Rapid prototyping's transformative role to the future of manufacturing

Rapid prototyping is significantly contributing to an innovative manufacturing future by enabling swift conversion from conceptual designs to physical models.

Understanding Rapid Prototyping

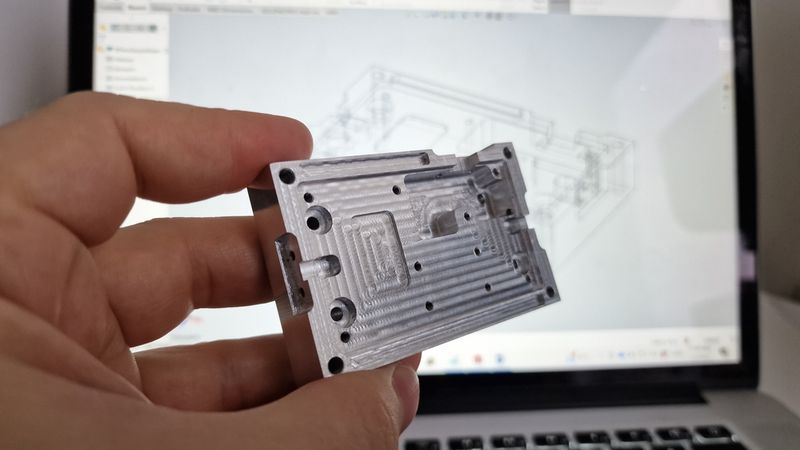

Rapid prototyping spearheads a shift in manufacturing, enabling the quick transformation of ideas into tangible products. This approach leverages cutting-edge technologies such as 3D printing, CNC machining, and additive manufacturing to facilitate fast-paced development cycles, crucial for staying competitive in today's market.

At the forefront of this transformation is BOEN, a company that's integrating advanced rapid prototyping techniques to offer flexible, cost-effective, and time-efficient solutions. Their services cater to a wide range of businesses, from startups dreaming big to global corporations looking for innovative manufacturing strategies. By reducing the time and cost associated with traditional manufacturing methods, BOEN empowers companies to experiment more freely with their designs, iterate faster, and bring products to market more quickly.

This shift toward rapid prototyping is not just about speed and efficiency; it's also about the democratization of manufacturing. By lowering the barrier to entry, rapid prototyping enables more creators to bring their visions to life, fostering a new era of innovation in manufacturing.

The BOEN Difference

BOEN distinguishes itself in the rapid prototyping industry through a blend of proprietary techniques and state-of-the-art technology. Their advanced approach combines:

Innovative Workflows: Streamlining the design-to-production cycle, BOEN employs agile methodologies that significantly reduce development time. Their seamless integration of client feedback loops ensures that prototypes meet or exceed expectations with minimal iteration.

Advanced Hardware: BOEN's investment in cutting-edge hardware, from 3D printers capable of producing complex geometries to sophisticated CNC machines for high-precision machining, sets a new standard for rapid prototyping. This hardware allows for a wide array of materials to be used, each selected through a rigorous materials science approach that matches the right medium to the project's specific requirements.

The synergy of these elements positions BOEN as a leader in rapid prototyping, providing unique technical benefits such as reduced lead times, increased precision, and greater flexibility in material selection. Their dedication to pushing the boundaries of what's possible in rapid prototyping not only accelerates product development cycles but also empowers innovation, making them a sought-after partner in the manufacturing sector.

Practical Impacts on the Industry

Streamlining the Design to Manufacturing Pipeline

Rapid prototyping significantly streamlines the journey from design to production, offering a profound impact on manufacturing efficiency and product quality. By enabling quicker iterations and faster validation of designs, organizations can drastically reduce development cycles and associated costs. BOEN plays a pivotal role in this transformation through its advanced prototyping solutions.

Leveraging state-of-the-art technologies, BOEN helps industries accelerate their design processes. For instance, the use of 3D printing allows for complex geometries to be created directly from digital models within hours, bypassing the lengthy traditional manufacturing setups. Similarly, CNC machining services offer precision in creating parts from a wide range of materials, further refining the prototype's fidelity to the intended final product.

Moreover, BOEN's emphasis on materials science ensures that each prototype not only meets design specifications but also simulates the functional and aesthetic properties of final products. This holistic approach to prototyping encompasses not just the physical creation of parts but also a rigorous assessment of how materials react under real-world conditions, leading to higher quality outcomes.

Significantly, BOEN's methodologies foster greater innovation. With reduced time and cost implications, companies are encouraged to explore more ambitious designs, test new concepts, and iterate more frequently. This democratization of high-quality prototyping serves as a catalyst for breakthroughs across numerous sectors, from automotive to medical devices, where the precision and speed of prototyping can mean quicker market entry and competitive advantage.

In essence, the services provided by BOEN underscore the practical benefits of rapid prototyping in today's fast-paced industry, emphasizing efficiency, quality, and innovation.

Opening Doors for Startups and Innovators

Rapid prototyping is a game-changer for startups and innovative companies, easing the path from ideation to realization with its cost-efficiency and flexibility. For ambitious projects on tight budgets, this methodology is a beacon, illuminating the route to successful product development without the hefty investment traditionally associated with manufacturing.

BOEN, understanding the unique landscape startups navigate, offers specialized services that align with the agile, innovative ethos of these ventures. Their approach demystifies the prototyping process, granting access to high-quality resources and expertise that were once the exclusive domain of industry giants.

The technical benefits provided by rapid prototyping, such as improved design accuracy, the possibility of iterative testing, and the capability to quickly adapt to feedback, are crucial for startups. These benefits enable a swift response to market demands or design challenges, enhancing market responsiveness.

Furthermore, BOEN’s solutions are not one-size-fits-all but are carefully tailored to meet the distinct needs of innovators. Whether it's selecting the right material for a prototype to test its durability or employing the most suitable prototyping technique to ensure cost-effectiveness, BOEN’s expertise proves invaluable.

This support empowers startups to tread boldly in competitive markets, making rapid prototyping not just a manufacturing approach, but a strategic asset for driving innovation and securing a foothold in the industry.

Beyond Prototyping: The Future with BOEN

From Prototyping to Low-Volume Production

The transition from rapid prototyping to low-volume production is a critical phase for any product development process, marking the shift from concept validation to market readiness. This stage involves:

Detailed Planning: Establishing a clear roadmap from prototype to production, considering timeframes, budget, and resource allocation.

Material Selection and Sourcing: Choosing materials that balance cost, performance, and availability for low-volume runs.

Manufacturing Technique Adjustment: Shifting from prototyping methods to those more suitable for small-scale production without compromising quality.

Quality Control Systems: Implementing stringent quality control measures adapted for low-volume production to ensure each unit meets the high standards set during prototyping.

Logistics and Supply Chain Management: Optimizing logistics to handle the distribution of smaller product quantities, managing supply chain relationships to ensure timely delivery of materials.

BOEN supports businesses through this transition by leveraging its expertise in both rapid prototyping and small-scale manufacturing. Their support encompasses:

Consultation and Strategy: Advising on the best pathways for scaling production in a cost-efficient manner while maintaining product quality.

Custom Manufacturing Solutions: Offering tailor-made manufacturing solutions that address the unique challenges of low-volume production.

Quality Assurance: Ensuring that the quality established during the prototyping phase is maintained or enhanced as production scales.

Supply Chain Optimization: Assisting in creating a responsive and efficient supply chain tailored to the needs of small-scale production.

Through these services, BOEN helps companies navigate the complexities of scaling their products, enabling a smoother transition from concept prototypes to market-ready products. This comprehensive support is invaluable for businesses looking to capitalize on their innovations with minimal delays and optimal product quality.

Empowering Innovation Across Industries

Rapid prototyping, especially when leveraged by BOEN's expertise, catalyzes innovation across various industries by providing tailored solutions that meet each sector's unique demands.

In the aerospace sector, precision and reliability are paramount. Rapid prototyping facilitates the production of lightweight, high-strength components, reducing aircraft weight and improving fuel efficiency. BOEN's adept material selection ensures components withstand extreme conditions, from high temperatures to mechanical stress, crucial for aerospace applications.

In the medical devices industry, the ability to prototype intricate, biocompatible devices rapidly accelerates the development of lifesaving technologies. BOEN's proficiency in navigating material compatibility and regulatory requirements allows for the swift iteration of designs, from prosthetics to surgical tools, ensuring they meet stringent medical standards. Low-volume manufacturing allows medical device products to be made in small batches, as medical devices, unlike consumer products do not require very large quantities.

The automotive industry benefits significantly from rapid prototyping by expediting the design process of both functional and aesthetic automotive parts. BOEN's expertise in durable materials and finishing techniques enables the production of prototypes that closely mimic final products, allowing for comprehensive testing and design optimization.

By overcoming technical challenges through innovative solutions and material expertise, BOEN not only advances product development within these sectors but also empowers companies to push the boundaries of what's possible, leading to groundbreaking innovations that reshape industries.

Conclusion

The journey through rapid prototyping's capabilities and its transformative impact on various industries has underscored its indispensable role in modern manufacturing. Through the lens of BOEN's innovative practices, we've seen firsthand how technological advancements in rapid prototyping significantly streamline the design-to-manufacturing pipeline, empower startups, and catalyze innovation across sectors like aerospace, automotive, and medical devices.

BOEN stands at the forefront of this revolution, offering expertise and solutions that not only meet the current demands of the market but also pave the way for future advancements. The potential for further innovation in manufacturing, driven by rapid prototyping, is boundless. We invite industry professionals to consider how these advancements could be integrated into their operations, ushering in a new era of efficiency and creativity.