Prototyping and production support for a fast developing medical devices company in Europe

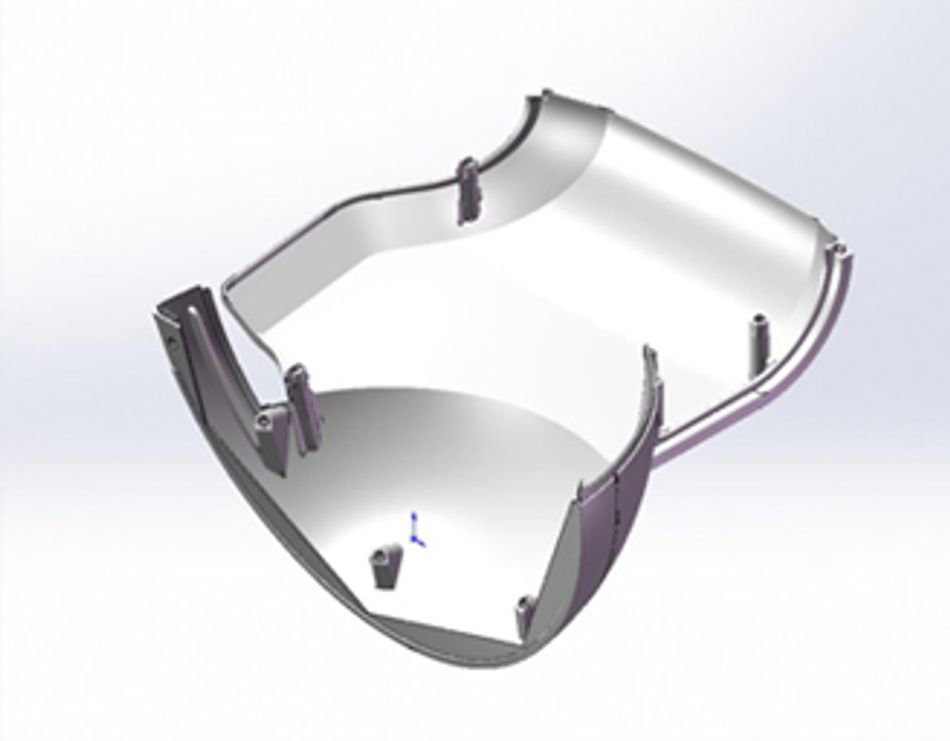

A rapidly-growing European medical device firm was looking for a partner for their high-end eye diagnostics device. Annual demand for this product is hundreds of units, with a design that could require modifications in order to respond to the changing market needs.

Project Background

A rapidly-growing European medical device firm was looking for a partner for their high-end eye diagnostics device. Annual demand for this product is hundreds of units, with a design that could require modifications in order to respond to the changing market needs.

RPWORLD Solutions

1. Process Selection:Combine urethane casting, injection molding, CNC and 3D printing.

(Traditional injection molding would require 2 to 4 months, cost over $100,000 and not permit major design changes once the mold has been made.)

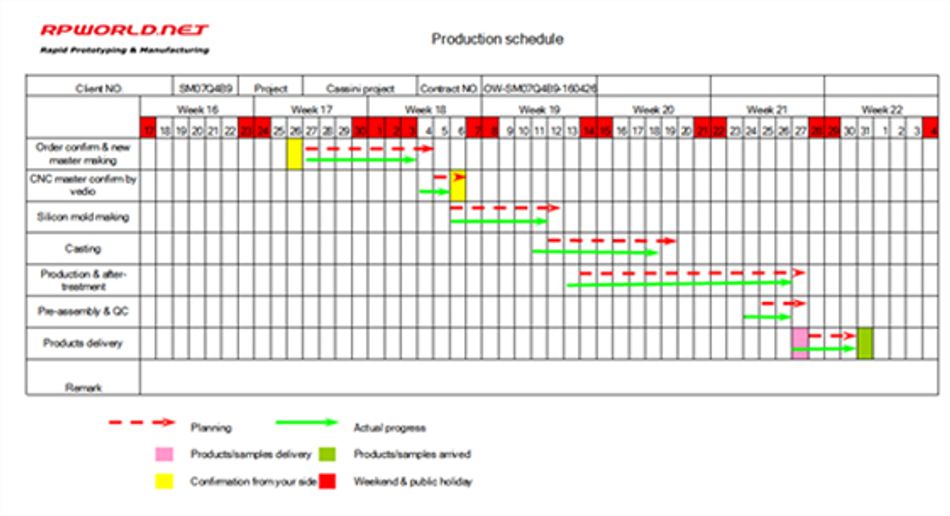

2. Project management:

3. Produce fixtures and gauge tools to ensure accurate hole location, tolerances and final assembly.

4. Cooper painting on the interior surface to achieve the EMC effect.

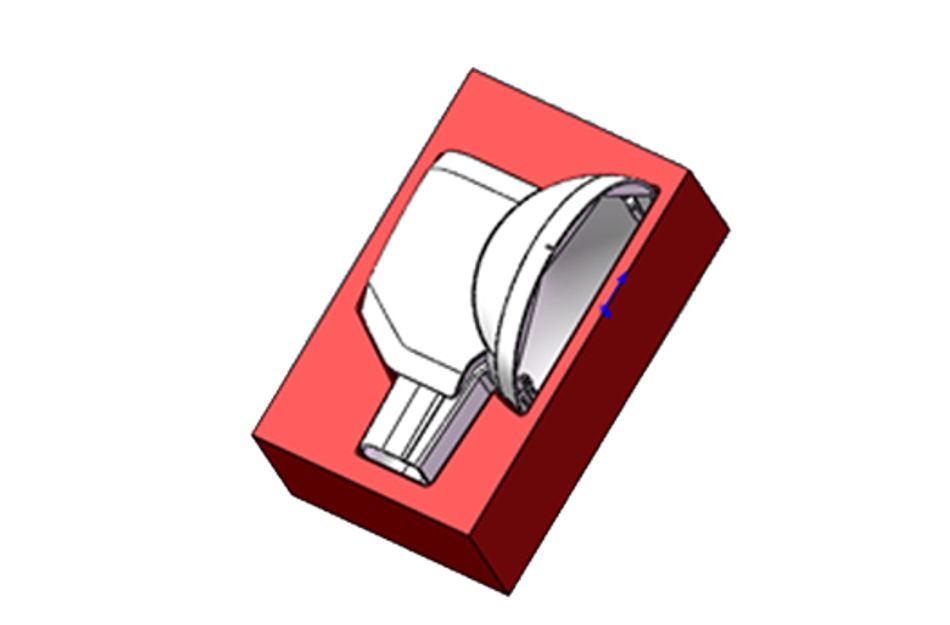

5. Customized Packing Solution: Designed by our engineering department for protection during shipment.

6. Engineering analysis and design optimization.

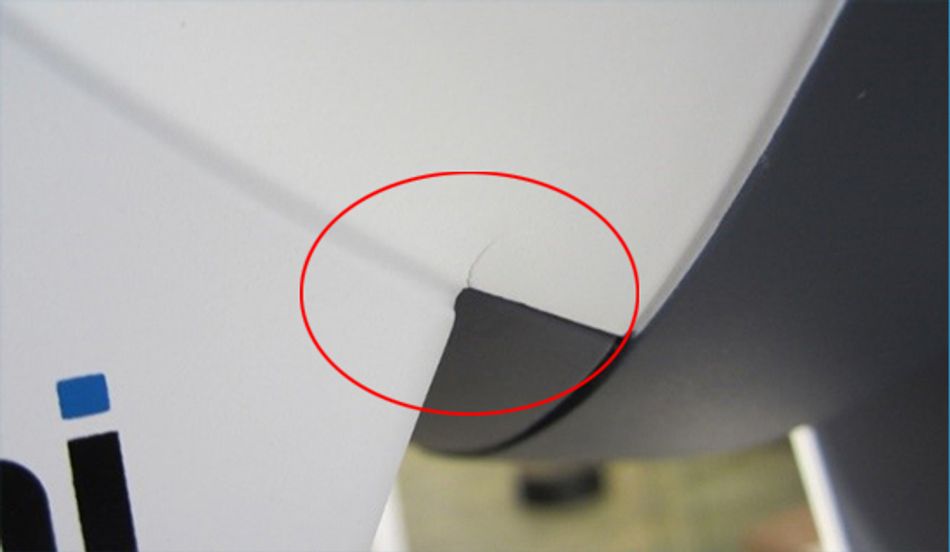

After Receiving The First Product Batch, The Client Detected A Crack On The Product.

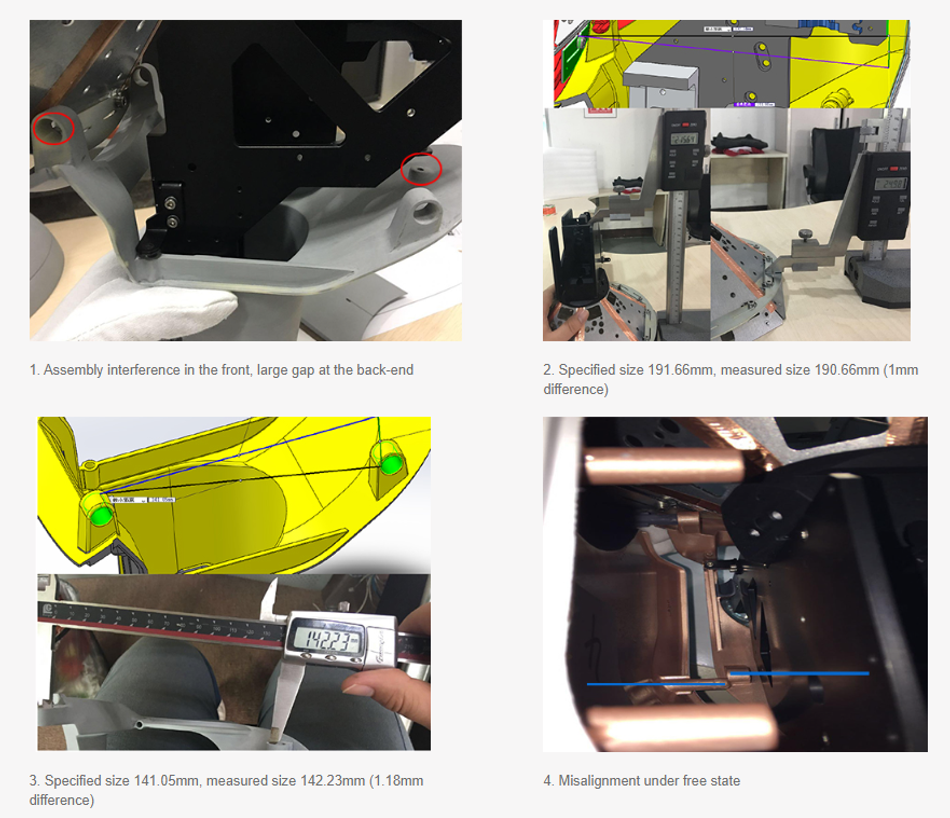

After further analysis, the client discovered that the rounded corner was smaller than what was specified in the 3D data (3D data R1.8 vs. measured size R1). The the round corner being too small led to stress concentration and cracking.

An Internal Meeting Was Held Once We Received The Feedback. We Determined That The Round Corner R1 Was Not The Cause Of The Crack.

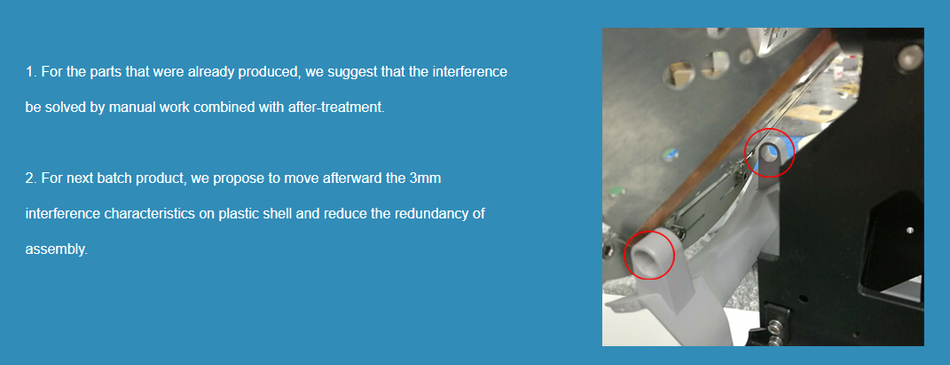

Force Is Required To Assemble Both Parts, Causing Significant Stress In The Plastic Shell Concentrated At The Rounded Corner. This Was Found To Be The Root Cause Of The Crack. We Submitted Our Analysis Report To The Client Along With A Suggested Improvement Plan.

The Improvement Plan Was Approved And The Crack Issue Never Occurred Again.

Customer Benefits

- With RPWORLD vacuum casting solution, the production time was reduced by 50%, we delivered 25 set in 4 weeks.

- Production cost was only 20%~30% of traditional tooling solution.

- Long term product development partner.

- Clients enjoyed smooth prototype testing and saved a lot of time and cost in R&D.

- All production, after-treatment and pre-assembly was provided by a single supplier, RPWORLD, which greatly reduced project risk.

- Close communication and professional coordination ensured high quality and launching schedule.

Postscript Note

- How to select the most suitable manufacturing solution to meet the customer's needs?

- How to attain the accuracy, exact heptagon structure and hole position?

- How to achieve the Electro Magnetic Compatibility (EMC) effect without affecting appearance?

- How to ensure high quality and launch the product as early as possible?

Feedback From The Client

Thanks a million for your great support, I sometimes have the impression you are in our office next door! What distinguish RPWORLD is your quick delivery times & flexibility, and good understanding of technical requirements.

- R&D Team Leader