Miniaturization Meets Performance: Designing Reliable, Wearable Devices for Diabetes Care

Engineers face multiple design challenges and constraints in the development of wearable diabetes devices. Smaller, reliable, and robust components are helping usher in the next generation of diabetes care devices.

The convergence of medical wearables, cloud-connected services, and chronic disease management is transforming personal healthcare. Nowhere is this more apparent than in diabetes care, where continuous glucose monitors (CGMs) and insulin pens are advancing beyond their therapeutic roles to become full-fledged wellness devices. Today, these tools extend beyond monitoring glucose levels and administering insulin, also contributing to a broader ecosystem of connected health through real-time insights and data-driven lifestyle management.

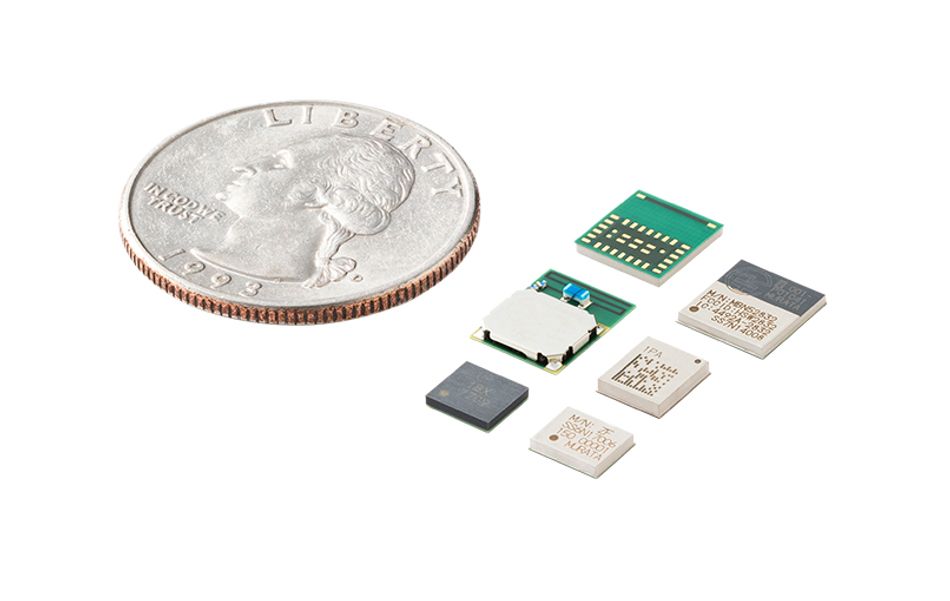

However, this new paradigm also introduces a cascade of engineering challenges. Designers are under pressure to develop devices that are small and comfortable enough for continuous wear, robust enough to deliver clinical-grade performance, and efficient enough to run on coin cells for weeks or months at a time. They must guarantee reliable wireless telemetry, tight timing synchronization, and EMC compliance within form factors smaller than a coin.

This article examines the design trade-offs and system-level constraints encountered by engineers developing wearable diabetes devices, as well as how component-level decisions can significantly impact product viability and user trust. It further explores how Murata is helping engineers solve these complex challenges.

Engineering Challenges in Wearable Diabetes Devices

Designing CGMs and insulin pens requires a delicate balance between user comfort, technical reliability, regulatory compliance, size, and power consumption. Each design decision impacts multiple subsystems, making integration an inherently multidisciplinary challenge.

Miniaturization Under Constraint

Both CGMs and insulin pens must maintain user discretion and comfort when worn continuously or used in public. But reducing size below 20 mm in width, while integrating wireless connectivity, battery, sensor, control logic, and signal processing, introduces non-trivial mechanical and electrical compromises.

Limited PCB area forces tradeoffs in component placement, thermal dissipation, and trace routing. Flex assemblies and stacked boards may solve form factor issues, but increase susceptibility to mechanical stress and thermal cycling under daily wear conditions. Designers must also manage strain at skin interfaces and enclosure seams, especially for adhesive-based CGMs.

Reliable Wireless Communication

For CGMs, wireless connectivity is a must, as telemetry to smartphones or cloud platforms is a major value-add for the entire user experience. Bluetooth Low Energy (BLE) offers a strong balance between interoperability and low power but requires precise antenna matching and timing synchronization. Signal attenuation from the body, risk of interference from nearby devices, and the need to conserve power during idle states all complicate system design.

Meanwhile, insulin pens increasingly incorporate BLE to log injection events and synchronize with mobile dose-tracking apps. These require occasional but reliable short bursts of communication, often from within unfriendly environments like metallic enclosures or dense purses and bags.

Power Management/Battery Life

CGMs operate continuously, sampling and transmitting at defined intervals, while insulin pens remain dormant for long stretches but must wake immediately and operate without error. Each mode imposes different demands on the power architecture, making it hard to optimize for a single use case.

Meanwhile, standard silver oxide and coin-cell lithium batteries are preferred for their small size and stable voltage, but energy budgets remain tight. Designers must reduce quiescent leakage to preserve standby life, then accommodate high peak currents during wireless bursts. Such a task requires transient energy buffering, impedance-matched converters, and smoothing capacitors to prevent brownouts or resets during mission-critical tasks.

Thermal and Timing Stability

Accuracy in sensing and delivery depends on timing precision and environmental compensation. For CGMs, sensor calibration relies on stable thermistor output and consistent clocking across temperature fluctuations caused by skin contact and ambient variations. Insulin delivery systems must coordinate timing for motor actuation, feedback sensing, and BLE handshake while maintaining sub-millisecond tolerances to guarantee proper dose logging or alerts. In both cases, timing errors can propagate into incorrect measurements or missed events.

Noise Immunity/EMC Compliance

Miniaturization often means placing analog, digital, and RF components in extremely close proximity, raising the risk of conducted and radiated interference. High-frequency switching noise from DC-DC converters can degrade sensor signal integrity or wireless reliability. Achieving compliance with IEC 60601 EMC standards requires careful filtering, shielding, and decoupling without expanding the footprint or compromising energy efficiency.

Design Best Practices and System-Level Approaches

Creating a reliable, compact diabetes wearable means optimizing a system where wireless communication, timing precision, power architecture, and electromagnetic compatibility (EMC) are all tightly interlinked. Engineering success depends on managing these interactions cohesively and holistically.

Start With Wireless

Wireless functionality sets the clock for everything else. Whether designers choose Bluetooth Low Energy (BLE) or low-power wide-area (LPWA) modules, these decisions define the antenna structure, enclosure tolerances, and energy budget. In miniaturized devices, embedded antennas are necessary, but they come with performance tradeoffs. Impedance matching becomes necessary, and designers must use compact LTCC filters and baluns to minimize return loss and preserve signal integrity. Moreover, wireless data bursts often create the system’s peak power draw, meaning RF design and power delivery cannot be decoupled.

Clocking and Timing Stability

Connection intervals and sensing schedules demand stable timing references, especially during sleep-to-wake transitions or during synchronized RF activity. Crystal units such as Murata’s XRCGB series offer low drift and small size to support reliable wake intervals and BLE synchronization. Since these clocks often govern duty-cycling thresholds and sensor polling rates, they directly influence battery life and system responsiveness. Therefore, clock selection is as much a power decision as a timing one.

EMC and Signal Integrity

The high density of mixed-signal subsystems in diabetes wearables creates inherent EMC risk. Co-located RF radios, digital control loops, and analog sensing channels can produce crosstalk or spurious emissions. Designers must deploy multilayer MLCCs, low-ESL EMI filter capacitors, and signal-line filters to maintain sensor fidelity and pass IEC 60601 certification. These measures protect both regulatory compliance and end-user safety, as well as product trust.

Power Architecture

Wearables must wake instantly yet consume virtually zero current while dormant. Batteries must handle both low leakage and transient surges. Voltage conversion stages (e.g., chip inductors, smoothing capacitors, and compact DC-DC modules) must deliver stable operation without adding bulk. Since every subsystem draws from the same energy pool, power must be conditioned to meet the strictest common denominator.

How Murata Solves These Challenges

Murata’s healthcare-focused portfolio directly addresses the engineering constraints that define wearable diabetes devices. With a focus on miniaturization, ultra-low power, wireless performance, and EMC robustness, Murata offers component-level solutions that reduce system complexity while enhancing overall reliability and compliance.

Connectivity Modules

Murata’s Bluetooth Smart modules integrate wireless radios, antenna matching, and regulatory certifications in a single compact form factor that is perfectly suited for CGMs and insulin pens. As highly integrated solutions, the modules simplify board layout and reduce the need for external RF components, which improves area constraints and sidesteps the impacts of parasitics.

Complementing these modules are Murata’s LTCC filters and baluns, including the LFL, LFB, and LDB series, which provide harmonic suppression on the transmitted signal and rejection of interfering signals on the received path in crowded RF environments. Collectively, these components help mitigate signal loss and interference, even when devices are worn against the body or carried in RF-hostile conditions.

Power Supply/Energy Efficiency

Murata’s coin lithium and silver oxide batteries deliver stable voltage profiles with exceptionally low leakage. For voltage conversion and conditioning, Murata’s NXJ1 and NXJ2 isolated DC-DC converter modules provide compact, energy-efficient power delivery to important subsystems like sensor conditioning and RF transmission. And, to handle the transient load from wireless bursts, Murata’s ECAS polymer aluminum electrolytic capacitors offer excellent smoothing and backup energy performance in a space-saving package.

Murata also supports low-power sensing through its AMR magnetic sensors, which consume less power than traditional TMR options and are ideal for injection detection and cap-on/cap-off state monitoring in insulin pens. The ultra-low-profile non-isolated power converters like PicoBK and MonoBK also offer powerful conversion solutions with minimal area requirements.

Miniaturized Passives and Noise Control

In high-density PCB environments, Murata’s multilayer ceramic capacitors (GRM and GJM series) provide low-ESR decoupling and high-frequency stability in extremely small footprints. For improved EMC performance, the NFM series low-ESL EMI filter capacitors suppress conducted noise at the power and signal lines while supporting IEC 60601 EMC compliance. Meanwhile, chip inductors from Murata’s LQP series provide impedance matching solutions for RF circuits and energy storage for switching regulators. Similarly, the BLF_RD and LQZ series filters suppress unwanted harmonics to enhance Bluetooth sensitivity and protect sensor integrity.

Timing and Sensing Accuracy

Precise timing is needed for wake-up cycles, sensor sampling, and wireless handshakes. To this end, Murata’s XRCGB series crystal units deliver reliable timing with tight frequency stability and excellent mechanical resilience in sub-millimeter packaging.

For thermal management and dose detection, Murata’s NCU series thermistors offer consistent temperature sensitivity. Meanwhile, AMR sensors provide highly stable magnetic sensing with lower current draw, resulting in longer battery life and improved detection accuracy.

Conclusion

Today’s CGMs and insulin pens are entering a broader category of intelligent, wearable health platforms. As these devices evolve to support early detection of metabolic disorders, stress and hydration monitoring, and even closed-loop drug delivery, their technical demands will only grow more stringent. Therefore, meeting these demands requires architecting systems where wireless connectivity, power efficiency, timing stability, and noise resilience reinforce each other.

Murata’s portfolio of miniaturized, power-conscious, and EMC-optimized components is built for exactly this kind of system integration. By offering modular building blocks, ranging from Bluetooth modules and DC-DC converters to thermistors, filters, and crystal timing devices, Murata unlocks faster and more reliable development cycles for next-generation diabetes care and beyond.