Managing Continuity and Unplanned Demand in Modern Manufacturing with Conrad

What if your next critical manufacturing project was halted by an unexpected supply chain disruption? In modern manufacturing, that is a constant risk. Staying on track requires agile sourcing, real-time coordination, and partners who can adapt when plans shift.

Introduction: Volatility Is the New Normal

Manufacturing today operates in an environment shaped by unpredictability. From raw material shortages and shifting trade policies to sudden demand fluctuations, volatility has become the norm. Businesses can no longer rely solely on static supply chains or long-term forecasts to stay competitive.

This article explores how engineering and sourcing teams can adapt to these realities. It looks at the evolving responsibilities of engineers, outlines key strategies for operational continuity, and highlights how Conrad has positioned itself as a high-service sourcing platform that supports manufacturers when flexibility matters most.

The Evolving Role of Engineers in Manufacturing

In modern manufacturing, the responsibilities of engineers do not end at design. They are increasingly involved in solving supply chain bottlenecks, identifying substitute materials, managing compliance workflows, and ensuring that what gets designed can actually be built.

This shift reflects a larger transformation in how manufacturing teams operate. Engineers must now collaborate more closely with procurement and operations. The boundaries between departments are dissolving, and cross-functional decision-making is essential. But without the right tools or transparency into sourcing and delivery timelines, engineers are often left to improvise, resorting to design changes or last-minute workarounds to stay on schedule.

Photo Credit: Kristof Lemp

The pressure to do more with less, faster, is not going away. That is why building resilience into the engineering workflow is no longer optional. It is a competitive necessity.

Strategy for Operational Continuity

Staying ahead of disruptions requires more than reactive fixes; it calls for infrastructure that supports speed, flexibility, and informed decision-making. Conrad has emerged as a key partner in this space, offering a sourcing platform designed to help engineering and procurement teams embed continuity into their processes from the start.

Photo Credit: Westend61/Getty Images

Through a combination of technical expertise, digital tools, and service integration, the Conrad Sourcing Platform delivers several strategic advantages:

Customized Sourcing: Not every situation can be solved with off-the-shelf solutions. Engineers often need tailored products that meet specific performance or size constraints. Conrad supports these requirements through custom sourcing, reducing the need for design rework and enabling faster deployment.

Integrated Logistics: Speed and predictability matter, especially when demand shifts mid-cycle. By managing the full product journey from factory to final destination, Conrad ensures better tracking, coordination, and fewer delays.

Early Compliance and Testing: Regulatory and safety requirements often delay product rollouts. Conrad helps customers handle certifications and quality checks early in the sourcing process, reducing friction and accelerating time-to-market.

E-Procurement Solutions: Conrad's ProcurePlus service streamlines procurement with features like multi-user access, approval workflows, budget controls, and customizable catalog views. It integrates seamlessly with Enterprise Resource Planning (ERP) systems and offers automated order tracking, making it easier for businesses to manage procurement with transparency and control.

Case Study: The “Baby Dummy” Story

The development of advanced safety systems in cars is evolving rapidly. One new requirement in the automotive industry is Child Presence Detection (CPD), a feature designed to detect if a child is accidentally left in a vehicle. Austrian company 4activeSystems created a lifelike newborn dummy to help test these systems.

This Baby Dummy mimics the appearance, movement, and breathing patterns of a real infant. It is made with advanced composite materials and is used in labs to validate CPD sensor performance. But as development progressed, 4activeSystems faced several rounds of rapid design iteration. This led to frequent changes in material requirements, including new sizes of connectors, sensors, chips, and other components.

Credit: 4activeSystems GmbH

Conrad stepped in as a high-service sourcing partner. Rather than simply shipping parts, Conrad worked closely with 4activeSystems to secure urgently needed supplies, handle logistics, and keep development on track, despite shifting technical demands. Their ability to respond quickly helped 4activeSystems maintain momentum without compromising quality or compliance.

"Conrad's long-standing presence and reliability in the field of electronic components made them a trustworthy partner for 4activeSystems projects." Simon Perle, Product Manager for Occupant Detection at 4activeSystems GmbH.

This collaboration was not just about parts; it was about partnership. And it illustrates the growing importance of agile sourcing in engineering-intensive fields.

Conrad’s Evolution into a Modern Sourcing Platform

Conrad has spent a century building its expertise and credibility in electronics. Starting as a radio parts supplier and evolving into a staple of the electronics industry, the company has continuously responded to market shifts and customer needs.

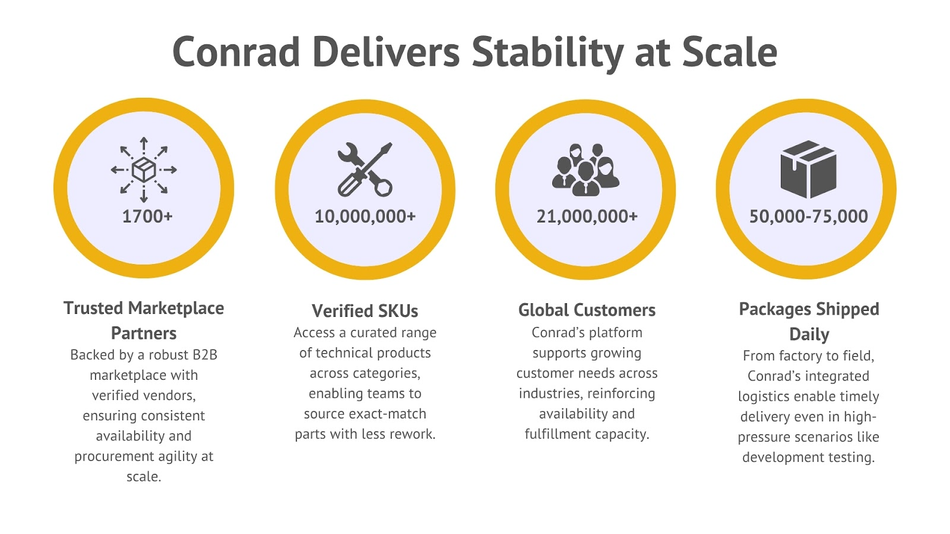

Today, Conrad is a high-service sourcing partner dedicated to B2B and industrial sectors. Its platform offers over 10 million verified products, but its strength lies in the comprehensive suite of services that support every stage of the manufacturing lifecycle:

Specialized and Secure Sourcing: Fast and reliable access to hard-to-find or alternative components, especially critical during design changes or shortages. All products are sourced from verified suppliers, helping eliminate risks related to counterfeit or gray-market parts.

Technical Project Support: Access to product specialists and engineering consultants helps resolve sourcing challenges, assist with prototyping, and keep complex projects moving.

Digital Procurement Tools: Conrad’s e-procurement tools offer features like catalog integration, role-based approvals, and real-time tracking, streamlining procurement workflows and improving visibility. With Conrad’s ProcurePlus, these capabilities expand to include supplier consolidation, spend optimization, and automated order handling for greater efficiency and cost control.

Compliance, Testing, and Quality Services: Support for early-stage regulatory compliance, measurement device calibration, and quality checks ensures that sourced components meet both operational and market requirements.

Custom Modifications: Conrad offers configuration services such as pre-cut cable lengths, bundled kits, and tailored assemblies to simplify deployment and reduce engineering overhead.

Flexible Ordering Conditions: Whether ordering in small batches or bulk quantities, customers benefit from fair pricing, consistent quality, and dependable delivery timelines.

Pan-European Fulfillment: Reliable logistics across Europe ensure fast delivery, while regional partnerships enhance Conrad’s ability to meet specialized sourcing needs.

As the Baby Dummy case shows, Conrad is more than a marketplace; it’s a continuity partner that brings technical depth, supply assurance, and procurement intelligence into one platform.

Final Thoughts: Engineering Continuity as a Competitive Advantage

Continuity in manufacturing isn’t the result of luck; it’s the outcome of intentional planning, the right systems, and dependable partnerships. As disruptions become the norm rather than the exception, the ability to adapt quickly without compromising quality is emerging as a key differentiator.

Engineering and procurement leaders who embed flexibility, digital visibility, and supply assurance into their operations are better equipped to deliver, not just under ideal conditions, but when it matters most.

Conrad makes this shift possible. It offers more than just components by delivering end-to-end sourcing support, integrated logistics, quality assurance, and e-procurement infrastructure that transforms uncertainty into strategic control.

Discover how Conrad can become your partner in operational continuity. Visit conrad.com and take control of uncertainty today.