Interview: How 3D Printing helps better shape ceramics

We interviewed Guillaume de Calan, engineer and co-founder of Nanoe, a ceramics material manufacturing company. Read how he set up his own Additive Manufacturing ceramics process, and what this combination allows for.

Guillaume de Calan

Meet Nanoe Cofounder Guillaume de Calan, engineer and Ecole Centrale de Paris graduate. He explained to us how Additive Manufacturing can be utilized for ceramics applications, and what the advantages it brings over traditional processes.

By setting up his raw materials manufacturing company, Nanoe 12 years ago, Guillaume specialized in technical ceramics manufacturing, which in turn led him towards metal and ceramics 3D printing.

Can you tell us about your background?

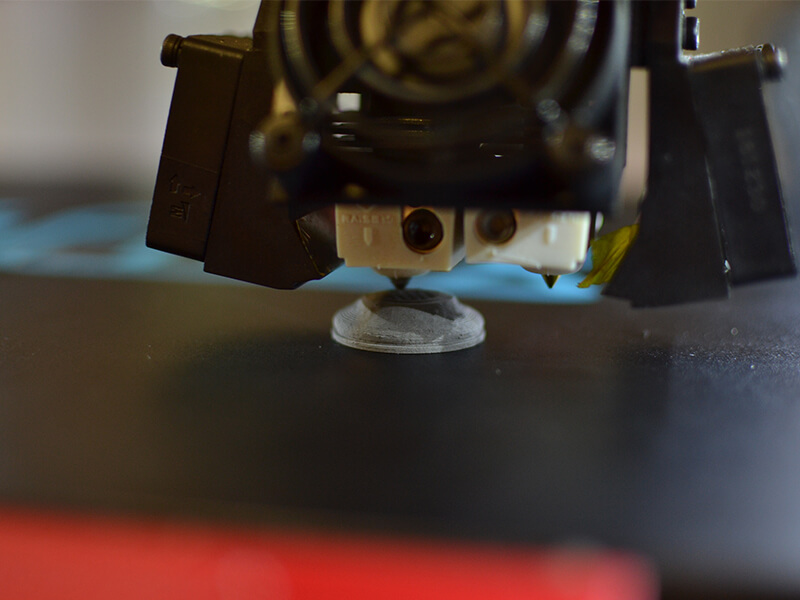

Nanoe has been for 10 years a raw material manufacturer, and what we do in 3D printing is linked to this activity. In 2018 we started a 3D Printing material range, which we developed from a filament line allowing for use fused deposition modeling (FDM) 3D printers. These materials are mostly used to 3D print ceramic parts, but also metal ones. To make this possible, we resort to indirect processes, that’s to say methods that rely on the 3D printing of parts out of powder mixes, which we bake in ovens afterward. That’s what we call sintering. 3D printing will give the part its shape, while the sintering operation will impart the ceramics with its density and mechanical properties. This part manufacturing approach has been developing lately, as it allows for productivity and cost gains, both for metal and ceramic parts.

Why did you start this 3D Printing raw material product range?

Until now, if you wanted to 3D print technical ceramics, there was only one technology available: Stereolithography. Though it performs very well, it works with closed, industry-oriented systems that are quite expensive and with a limited spread.

It seemed to us that an offer was missing here, in other words, an offer that would allow to start 3D printing ceramics easily. Our partners often shared with us that 3D printing was important, even though they didn’t necessarily have clear ideas upon the parts they would make with it. For this reason, they don’t want to invest significant amounts in 3D printers. They want to start small, making prototypes, small parts, and demonstrators they can show their customers. Then, if that’s relevant, they invest in a different technology at a higher cost.

As to us, this solution requiring a low investment is the one we wanted to provide. The fused deposition modeling systems we market are simple and cost-efficient. With a small investment comprising both a 3D printer and an oven, we can start 3D printing ceramic and metal parts, and that’s something that didn’t exist before.

Can you tell us about the applications of ceramics?

When referring to ceramics, we are talking about technical ceramics, which we resort to when other materials can’t work. We use it for loads that metal and plastic parts can’t deal with, that’s to say extreme conditions such as high temperatures, chemical applications, and friction. Hence, this material can be found in the manufacturing of parts subjected to high temperatures like: Resistor carriers, gas lines, probes or even foundry cores. A sizable segment lies in the Medical sector, as ceramics are biocompatible materials.

What are the benefits of 3D Printing for technical ceramics manufacturing?

We observe quite common usages of 3D printing among our customers, such as small-batch manufacturing, intended for parts tailored to their production needs.

This room for customization is something the Medical area values, for instance for patient-specific part manufacturing. Much work has been achieved in cranial reconstruction, which requires ceramics implants dimensioned to the patients’ scans. Other than small batches and unique parts, 3D printing is also interesting because it can shape ceramics better than any other process. This material isn’t easy to work, and there is a certain amount of parts we wouldn’t be able to manufacture without 3D printing.

How did this idea of combining Additive Manufacturing and ceramics production arise?

As a raw material manufacturer, we always adopted this approach of developing products adapted to our clients’ processes. Yet, when one is into ceramics, several processes such as injection molding exist. We hence wondered what process would be the next one to come, and it appeared clear to us that developing 3D printing materials was paramount. We then had to come up with our own open 3D printing technology, with which to use these raw materials.

Did you enjoy this interview ? Discover how 3D Printing push the eyewear, the medical and other industries forward from real people.