Injection molding vs 3D printing: Which one should you choose?

What are the differences between injection molding and 3D printing? Discover which manufacturing technique is best for your project.

3D printing vs injection molding

While starting your project, you are starting to think about the manufacturing technique you will use. How to choose the most adapted manufacturing technique? Today, we are going to see the differences between injection molding and 3D printing, in order for you to decide which one of these techniques might be the best to give life to your project.

Time, budget, precision, volumes, we will see all the pros and cons of injection molding and additive manufacturing. Follow the guide and find out the strengths and weaknesses of both these processes! Injection molding vs 3D printing: Which one should you choose?

Choosing the right manufacturing technique

3D printing and injection molding are two great manufacturing processes, but they are really different and can help you achieve different projects. This totally depends on your needs. Even if injection molding always seems more professional, some things now start to change and 3D printing is becoming a real alternative, allowing to create really accurate parts.

These two techniques can help you with both your rapid prototyping process and your production. They both have their own advantages, which one will bring more benefits to your manufacturing process, that is why, first, you will have to understand their differences.

What is the difference between injection molding and 3D printing?

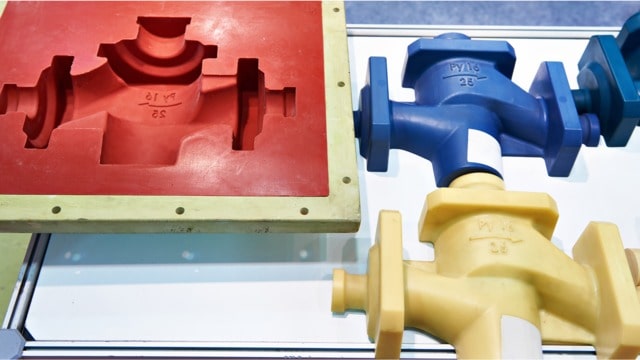

Injection molding

Injection molding is a traditional manufacturing technique. With this process, you produce parts by injecting material into a mold cavity in order to create your part. This manufacturing technique is shaping your products by injecting molten material into the mold, the material will then cool down and take its final solid shape.

https://www.ien.com/product-development/article/21014543/what-products-can-be-made-from-injection-molding

https://www.ien.com/product-development/article/21014543/what-products-can-be-made-from-injection-molding3D printing

3D printing is an additive manufacturing process, meaning that the whole manufacturing is made by adding material layer by layer. Using this process, there is no need to create a mold to produce your part, you will only need a 3D file. A lot of different 3D printing technologies and materials are currently available on the market.

When should you use each process?

How to use injection molding?

You can’t just use this technology like this, without any special equipment. Indeed, specific professional machines are needed to use injection molding. These injection molding machines contain a material hopper, an injection ram, and a heating unit.

Making molds for your injection molding process is a bit expensive, and reduce the possibilities when it comes to prototyping: If you need to make several iterations, it can be quite expensive to recreate molds each time. As these molds are usually made of steel, it is a bit complicated to make changes and could not be adapted to your prototype development.

However, if you are planning to produce large volumes, it is a good solution. Just keep in mind that this technique still includes high costs for injection molding tooling and large required turnaround time.

How to use 3D printing?

There are several ways to use additive manufacturing. You can get yourself a 3D printer, like an FDM (Fused Deposition Modeling) printer, if 3D printing filament is what you need. Your company can also invest in bigger and professional 3D printers, such as SLS (Selective Laser Sintering) 3D printers. But getting your own industrial 3D printer might be an expensive investment for your company, and it is maybe not worth it.

Or you could use a 3D printing service such as Sculpteo, giving you access to 75+ combinations of 3D printing materials and finishings. From metal to plastic and resin, 3D printing technologies will help you create all your best projects. Multi Jet Fusion, CLIP (DLS), DMLS, 3D printing technologies are numerous!

You just have to upload your 3D design, choose your technology, materials and finishing on Sculpteo's online 3D printing service. You will have an instant quote and receive your parts in only a few days.

What about you? Which one should you choose?

Benefits of injection molding

Injection molding is offering great advantage to produce your large volumes, with a great precision and perfect repeatability. While using plastic injection molding, you will have the choice among a wide range of materials. There are actually thousands of variations within each material, which will lead to different properties each time. Material weight, cost, flexibility, just for plastic properties and possibilities seem to be endless.

We already said it, injection molding is good for mass production, but also to create really detailed features. Due to the pressure of the process, it is really easy to add details to your parts created with injection molding.

Injection molding makes it quite easy to create parts with enhanced strength. Indeed, plastic injection makes it possible to use fillers in the injection molds.

Benefits of 3D printing

Using additive manufacturing is offering many advantages, making it a real alternative to traditional manufacturing techniques.

First, 3D printing is perfect to make iteration. For a long time, additive manufacturing was considered a rapid prototyping technique. It is not the case anymore, as it also became quite a reliable manufacturing technique. But prototyping quickly and easily is still among the best advantages offered by this manufacturing technique. While using additive manufacturing, you can print your project in order to test it, make all your modifications using your 3D modeling software, and print it once again to validate your changes. The flexibility of this process will help you save time and money, but also help you improve your product design.

Using 3D printing is also helping to avoid material waste. If injection molding was first seen as a manufacturing technique producing low scrapes, compared to processes like CNC machining, it appears that the winner in this category is the 3D printing technology! While 3D printing, you only use the amount of material you need for your whole project.

With 3D printing, you can also avoid inventory problems and costs by improving your storage and supply chain management. Indeed, you can 3D print your 3D design whenever you need it! You don’t have to think about your storage!

No more busy warehouse, the use of 3D printing for production can lead to a dematerialization of the supply chain. It could be the occasion to rethink the whole manufacturing process of your company and reduce tooling investment. What does digital inventory mean? This solution is simply to create your parts on-demand thanks to 3D printing. No need to store the part, you can simply print them when you need them.

We hope this blogpost helped you understand the advantages and disadvantages of these two manufacturing methods. 3D printing vs injection molding, which one will you choose? Share your point of view on these two techniques in the comments.