In-House vs. Outsourced 3D Printing: Choosing the Right Path for Your Business

The 3D printing world is evolving rapidly, offering new business opportunities. But with this comes a crucial decision: invest in 3D printing equipment or outsource? Both options have merits and drawbacks, and the best choice depends on specific business factors. Learn how to decide smart.

In-House vs. Outsourced 3D Printing

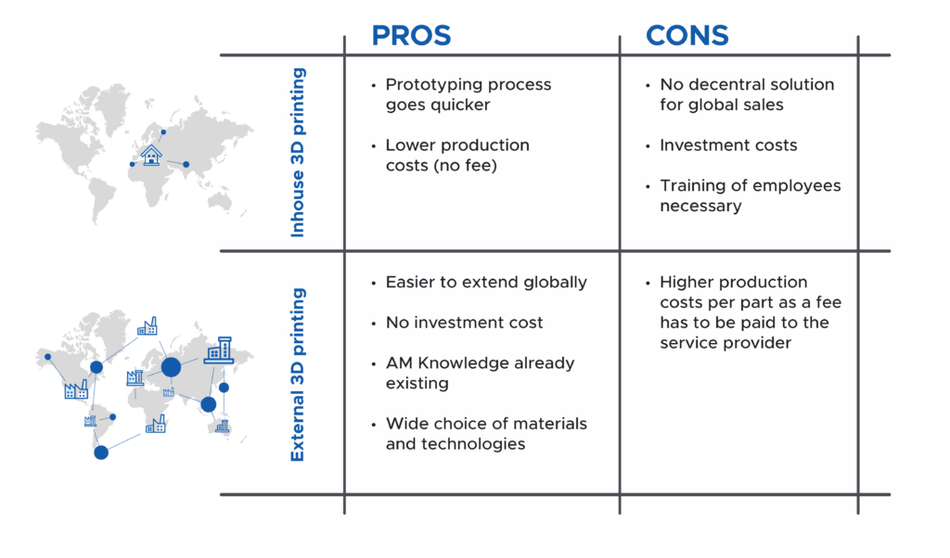

To say upfront, there is no simple answer and there are pros and cons for each option. However, this guide should help you in finding the right decision. We have established 6 factors you need to consider when deciding between inhouse and external 3D printing.

Location & Logistics

Consider the geographical reach of your operations. If your products or parts are required solely within a specific region, in-house printing might be the most efficient route. This allows for centralized production and quicker delivery times. However, if your business needs extend globally, outsourcing to geographically dispersed printing services or platforms can save you time and money on shipping.

Design Flexibility & Prototyping Speed

One of the biggest advantages of 3D printing is its design flexibility. In-house printing allows for rapid iteration during the prototyping phase. Need to make a quick design change? Having your own printer eliminates the need to wait for external services and allows for on-the-fly adjustments. This is crucial for businesses that rely on rapid prototyping to bring innovative products to market quickly. However, for smaller series production runs where the design is finalized, outsourcing can be a more cost-effective solution.

Scalability & Part Volume

The number and variety of parts you require will also influence your decision. If you plan to produce a wide range of products, each potentially needing different materials and printing technologies, in-house printing might become complex. Managing a diverse setup with multiple printers and materials can be a challenge. In such cases, outsourcing allows you to tap into the expertise and resources of established printing services, reducing your internal complexities.

Part volume also plays a role. Outsourcing is often more cost-effective for high-volume production runs or situations where you only need a few parts per week. Mid-range volumes, however, can be efficiently handled in-house, allowing you to maintain control over production schedules and quality.

Investment & Operating Costs

Investing in industrial 3D printers requires significant upfront costs. This includes not only the machines themselves but also maintenance, training for your staff, and a steady supply of materials. If your production volume is not high enough or the innovational power, you might consider outsourcing your needs, as they eliminate these upfront investments. You simply pay for the printing service you require. However, this convenience comes at a additional cost per part.

Expertise & Quality Control

3D printing involves specific design and production knowledge to ensure high-quality parts. If your team lacks this in-house expertise, outsourcing can be a safer option. Reputable printing services have the knowledge and experience to produce parts that meet your specific requirements. However, if developing internal expertise aligns with your long-term goals, you can consider training your staff or hiring individuals with the necessary experience.

Time Constraints & Efficiency

Time is a crucial factor in today's fast-paced business environment. If you need to get started quickly, outsourcing allows you to avoid the time needed for purchasing, installing, and training your staff on in-house printing equipment. However, if in-house printing aligns with your long-term vision and production needs, the initial setup time might be a worthwhile investment.

The Hybrid Approach: Combining Strengths

In some cases, the ideal solution might lie in a hybrid approach. You can maintain an in-house printing setup for handling specific parts or prototyping projects while outsourcing other printing needs. Platforms such as ours are emerging that simplify this process. By connecting your in-house printers with external services, you can leverage a larger network of printing capabilities and have parts printed on-demand based on location needs.

The Final Decision

Ultimately, the decision of whether to invest in-house or outsource your 3D printing needs depends on a thorough evaluation of your specific business requirements. Consider factors like production volume, geographical reach, design flexibility needs, and budget constraints. Don't hesitate to seek guidance from experienced 3D printing professionals who can help you analyze your needs and recommend the most suitable solution for your business success.

You want to implement 3D printing in your processes and are searching for an easy and scalable solution? Contact us and we can discuss your possibilities