Immersive Technologies in Medical Education

Article #6 of Improving Lives with Digital Healthcare Series: Immersive technologies enabled by modern sensing and connectivity systems can be effective pedagogical tools in making medical education safer, accessible, personalized, and engaging.

Source: Jelvix

This is the sixth article in an 8-part series featuring articles on Improving Lives with Digital Healthcare. The series focuses on electronic systems that enable innovation in the healthcare industry. This series is sponsored by Mouser Electronics. Through the sponsorship, Mouser Electronics shares its passion for technologies that enable smarter and connected applications.

The lockdowns imposed throughout the world since the beginning of the coronavirus pandemic made us realize the real need and potential of working online. From consulting a doctor to taking a course for becoming one, everything is shifting towards being online. Schools and Universities have also turned to an online/hybrid mode of education to protect the students from getting infected.

The new education pattern can be executed successfully for non-tech courses, but for medical and engineering students, a more practical approach was required. The current state of online education doesn’t offer all the contextual support of in-person learning The aim of this article is to discuss how immersive digital technologies can solve this problem by coming up with new ways to make learning more engaging through lifelike experiences.

Immersive Technologies as Pedagogical Tools in Medical Education

The healthcare sector is actively searching for prompt solutions to help increase efficiency and optimize the overall system. Medical education may close any potential gaps through technological advances coming along due to Artificial Intelligence (AI), Augmented Reality (AR), Mixed Reality (MR), Virtual Reality (VR), and eXtended Reality (XR).

Training with immersive technology provides several key benefits to learners and teachers alike. One way these technologies can reshape and enhance medical education is by moving knowledge acquisition beyond static presentations. Let’s look at what may drive this adoption.

Safe Environment

One of the benefits of medical training using immersive technology is that it provides a safe environment to learn. Across the world, people have been pushed out of the offices, the classrooms, and into their own homes in the name of safety, a duty of responsible behavior toward others, and containment. Interactive methods such as Zoom and Microsoft Teams have exploded and are used by almost everyone. But how can one train to be a doctor or a nurse just by interacting over video?

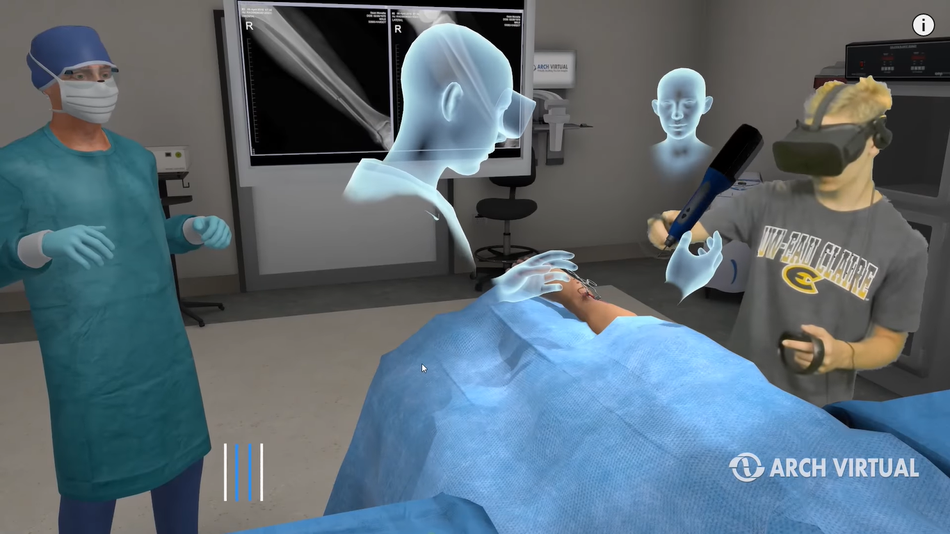

Immersive technology allows students to practice utilizing simulations on a host of healthcare issues with different people and teams. Medical simulations allow this practice to happen from a distance. It is no longer necessary to be in a hospital, an operating room, or a classroom. Immersive technology allows the requisite variety of skills to be brought to bear in a digital domain. Since practice through simulations may be easily set up and adjusted, it offers a risk-free environment to apply learned theory, making it a safe environment to enhance skills through repeated practice.

Accessible Technology

Medical equipment is costly and sensitive. What if medical equipment and the corresponding techniques to employ it could be emulated on computers and digital devices specially equipped for the required tasks? Headsets with accompanying tactile controls have been commonplace for gaming and are now moving into the medical and educational fields. The costs for this type of equipment are usually less than the actual physical medical equipment itself.

By learning and practicing in the digital realm, more people can access the learning content and get trained in the procedures and processes required. Just as flight simulators help aircraft pilots train, the medical instructor may perform a multitude of scenarios conveniently and cost-effectively in the immersive space. AR, for example, is accessible on mobile devices. It enables users to ‘see’ more by offering three-dimensional (3D) or 360° views. MR enables medical training students to interact with their colleagues and see the same relevant data and information as if they were in the room itself. This allows individuals to gain new perspectives and insights.

Personalized Content

Immersive technology may be personalized. It may be set up to respond both to the users’ personal manipulations and the medical training instructor to accentuate learning in areas where the student may require more attention and focus. It will also provide instructors with the ability to tailor the content fed to the student and respond to their queries, establishing a personalized feedback loop that can be positively positioned and reinforced over time by the instructor or via AI. Its convenience allows for self-paced customized training.

Engaging Experience

While utilizing immersive technologies, physical senses are led to take their experience as all-encompassing reality, merging the material and the digital realm. Because the student experiences the immersion technology as real and their attention is focused entirely on their environment, they absorb more of it. Just as no one goes to sleep or daydreams while scuba diving, because of the real difference in the contextual experience, the student who learns with immersive technologies will be more engaged. Through repeatable practice simulations, the student can develop competency and confidence.

Advancing Immersive Technology in Medical by Molex

Electrical power in the form of various voltage and current signals is required in every electronic circuit. This includes everything involving immersive technology designs for medical training. Molex brings decades of experience in advanced electronics, connectivity, and sensor technologies to help transform medical and pharmaceutical solutions. Molex works with designing, developing, and delivering cutting-edge medical device solutions that will enable the next generation of medical training and learning.

High-Performance Connectors for Power Delivery

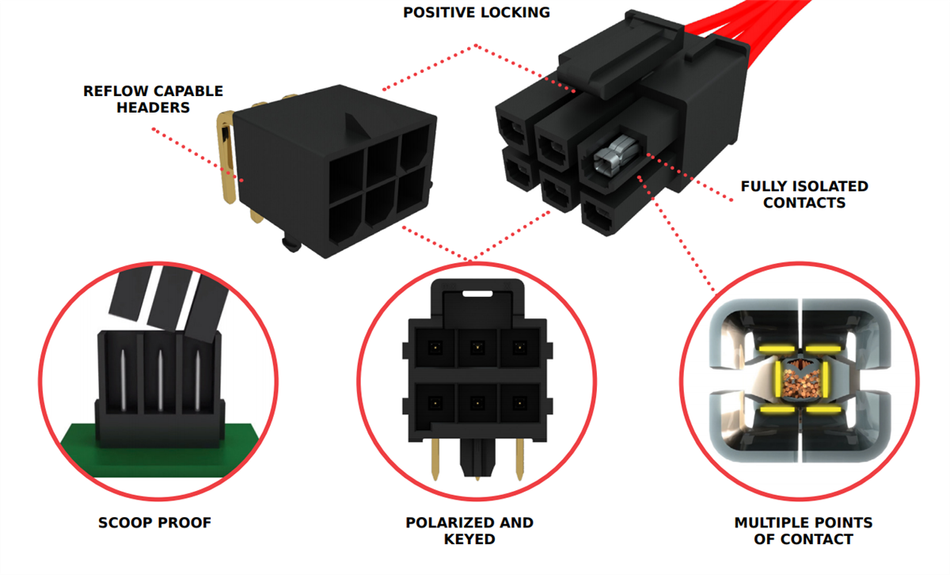

Molex FiT Family Power Connectors offer various connectors with colored, polarized housings with isolated terminals, terminal position assurance (TPAs), positive locks, and tangless terminals (Figure 4). Molex FiT Dual-Row Connectors provide power delivery and power distribution in wire-to-wire, wire-to-board, and board-to-board configurations. These off-the-shelf connectors can be modified, customized, or adapted to meet virtually any application need.

This family’s mechanically keyed feature allows the same circuit, and multiple connector use with virtually no chance of cross mating while making soldering easy. Terminals in Molex’s FiT families feature numerous contact points, so if one part degrades or becomes blocked by debris, the other contact points continue to carry the load. As a result, terminals have redundancy and a higher current-carrying capability. Molex’s FiT families feature positive locking latches designed with an audible click to give operators feedback that the parts have been securely mated.

With a scoop-proof design, contacts are protected until the mating connectors are correctly aligned. Therefore, damages related to aggressive unaligned mating and unmating are virtually eliminated. Molex’s FiT families feature fully isolated contacts that inhibit arcing between contacts and provide the use of higher voltages, as well as better electrical isolation between adjacent contacts. As a result of isolating the contacts, damage can be prevented during handling, and shorting risks due to debris are minimized.

Flex Cables that Bend but don’t Break

Molex/Temp-Flex manufactures specialty wire and cable to provide technological solutions to the medical, aerospace, military, datacom, testing & measurement, and industrial markets. Molex/Temp-Flex products are made in a fully equipped, on-site manufacturing facility to ensure quality and consistency. An extrusion process is employed using fluoropolymer insulation with a concentration on thin walls for the medical industry and faster speeds in the electronics industry. Typically designed for extreme conditions and harsh environments, all Molex/Temp-Flex product lines adhere to RoHS compliance standards.

Molex/Temp-Flex Foam-Core Ultra-Low-Loss Coaxial Microwave Cable combines space-saving with an effective dielectric. The fluoropolymer insulation eliminates the “phase knee” effect and delivers linear electrical length and stable performance at room temperature. Fluoropolymer insulation is characterized by high resistance to solvents, acids, and bases, making it ideal for medical applications. The cable achieves 80% velocity of propagation (VOP) loss characteristics. It also offers shielding greater than 100 dB at high frequencies.

Conclusion

As the coronavirus pandemic has clearly shown, the world needs more professionals to ensure the health of the community. As society works to meet the collective needs of us all, we must take advantage of the technologies around us to make life and healthcare learning experiences better. Immersive technologies are one of the ways we can produce medical education that's safer, accessible, personalized, and engaging.

This article was initially published by Mouser and Molex in an e-magazine. It has been substantially edited by the Wevolver team and Electrical Engineer Ravi Y Rao. It's the sixth article from the Improving Lives with Digital Healthcare Series. Future articles will introduce readers to some more interesting applications of electronics in healthcare.

Introductory article covered the fundamentals of biomedical instruments and the ways in which digitizing them is transforming healthcare.

Article 1 explored the design challenges in Consumer and Medical wearables. It showcased how technologies once limited to hospitals are now made available to everyone for monitoring personal health.

Article 2 was focused on the present state of robotic surgery. It explained how advancements in robotics and communication, combined with the expertise of surgeons, enable customized treatments for patients.

Article 3 presents an overview of how new sensing, communication, and energy systems, engineered for the healthcare sector can be used to transform cardiovascular disease treatment procedures.

Article 4 examined Brain-Computer Interfaces and how they help in enhancing human vision, motor recovery for disabled limbs, and more.

Article 5 featured an informative webchat between Mike Depp, and Glen Capek from Molex, as they discussed trends in flexible electronics driving new solutions for medical wearables applications.

Article 6 discussed how immersive digital technologies like Augmented Reality (AR) and Virtual Reality (VR) make medical learning more engaging through lifelike experiences.

Final article was a roundup of the entire series that tried to give readers a snapshot of the potential of medical technologies in the present times.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.