How Advanced Driver-Assistance Systems (ADAS) Impact Automotive Semiconductors

Vehicles increasingly contain electronic systems that assist drivers with monitoring, warning, braking, and steering tasks. Semiconductor companies are innovating to increase safety, while reducing weight, size, and complexity.

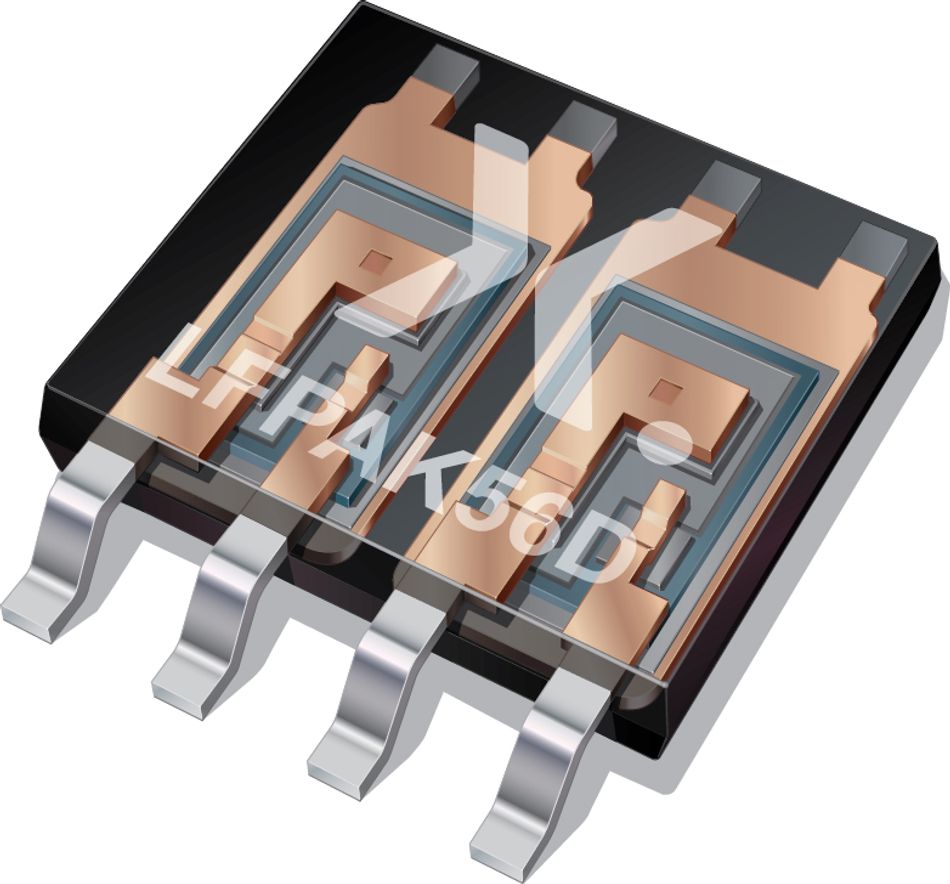

Dual MOSFETS

This article is part of a series about ADAS and Autonomous Vehicles, sponsored by Nexperia. We'll start the series by unpacking the concept of ADAS and exploring its impact on the world of semiconductors. The article is written by Ahmed Faizan Sheikh and co-authored by Ian Kennedy and Wayne Lawson.

The second article will dive into new semiconductor products that can increase reliability and performance in electrical automotive systems. Find it here.

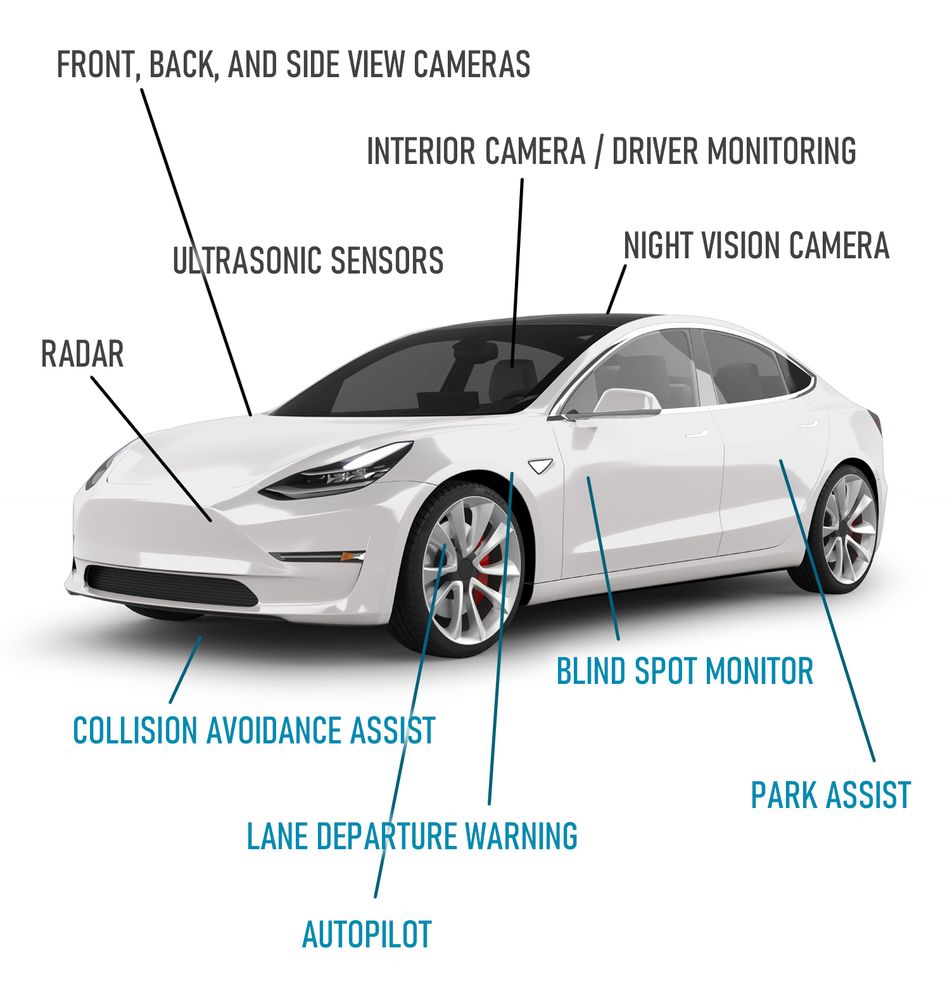

Advanced Driver-Assistance Systems, also known as ADAS, are electronic systems that help with monitoring, warning, braking, and steering tasks in a vehicle. These technologies exist at different levels. For example, infotainment systems, rear-view cameras, blind spot, and lane departure warnings are applications of this technology which empower the driver with crucial information but also let them exercise control over the vehicle at all times.

Next are semi-autonomous systems (SAS), like lane-keep assistance, which enable the vehicle to control itself for a brief period but allow the driver to override the automatic control when needed.

Lastly, highly autonomous systems are the ones that take full control of the vehicle at times, like during automatic parking.

All these subsystems come together to realize automated and semi-autonomous systems. From electronic stability control systems which help drivers regain control of their vehicles as needed, adaptive headlights which adjust their direction and intensity as per the road conditions, a rearview video system which allows the driver to see the area behind the rear bumper, adaptive cruise control which determines the speed of the vehicle based on the position of the driver’s vehicle with respect to the vehicle in front, and so on.

Components of ADAS

Quite predictably, ADAS has played an important role in the development of autonomous cars and will play an even critical role in the years to come. But before we delve deeper into this, let’s understand how ADAS works and what makes up an ADAS system.

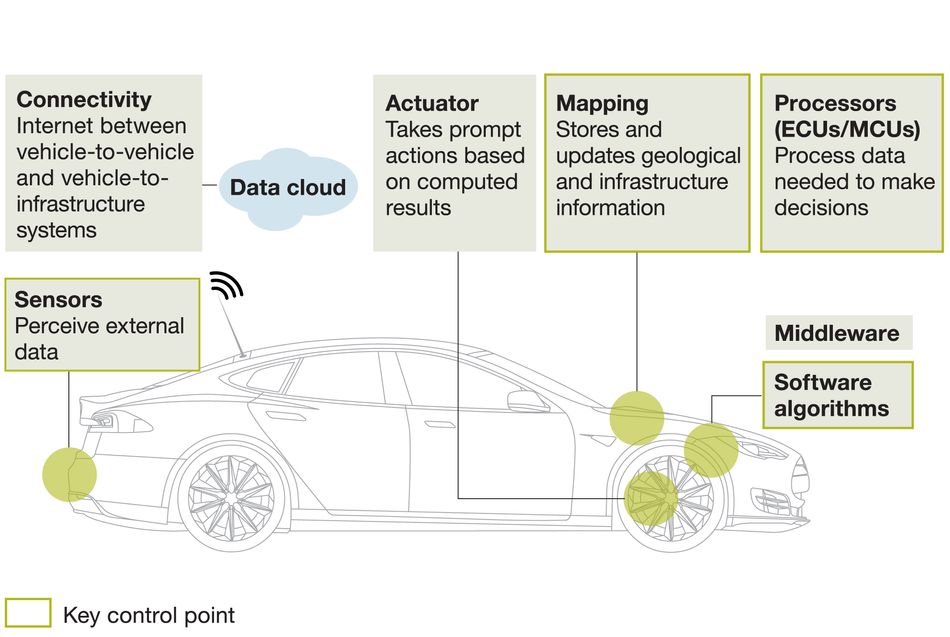

Sensors

Sensors capture real-time actionable data from the environment that provide input for the various Advanced Driver-Assistance Systems in a vehicle. Commonly used ADAS sensors include cameras, ultrasonic, radar, and Lidar sensors. They’re often located in the rear and front bumpers of the car and side-view mirrors.

Software & Data

Most automotive companies are employing advanced software to process the incoming sensor data, learn and make decisions, and actuate the hardware for a specific response. Machine learning and artificial intelligence are ruling the industry and feeding the algorithms to decide how to behave in varied situations.

The mapping functions of ADAS are used to collect and store geographical and infrastructure data related to vehicle sensors.

Processors

Electronic Control Units (ECUs) and Microcontroller Units (MCUs) are the hardware components (the electronic circuitry) that the software runs on. They are often dedicated to a single or narrow range of tasks, so with increasing ADAS applications, the number of processors is likely to increase as well. However, increasingly vehicle manufacturers are changing their approach from embedded software that is running on ADAS-specific ECUs to higher-level software platforms running on centralized ECUs or MCUs.

Recommended reading: Putting high-performance computing into cars: automotive discrete semiconductors for autonomous driving

Actuators

Actuators execute the decisions made by the system. They come in many forms, depending on the ADAS system. For example, displays that provide information, or actuators that control the engine and steering for adaptive cruise control or lane-keep assistance.

Centralized vs. Decentralized ADAS System Architecture

As you can sense, with increasing capabilities and a larger number of sub-systems comes increasing complexity. One of the key questions on how to achieve highly effective sensing & processing evolves around the concept of sensor fusion and the question of implementing a centralized versus decentralized architecture for fusion.

Centralized ADAS System Architectures

In a centralized architecture, all the Remote Control Units (RCUs) are directly connected to a central control unit. For instance, Lidar and ultrasonic sensors will be located in two different locations of a vehicle and will perform two different functions. These sensors will gather input and send it to a central control unit which processes the data.

Decentralized ADAS System Architectures

A decentralized fusion system consists of a network of sensing units, each with an ability to process its raw data and communicate with the adjacent nodes.

Which architecture is the right one?

It is tough to determine as to which architecture is the right way to design a self driving car. Centralized architecture could sound like a better option as the measurements from different sensors are independent quantities and not influenced by other nodes; there are two drawbacks. There should be enough communication bandwidth to transport the raw data to the centralized node. This essentially means high-power processing, and this could prove to be costly.

On the other hand, decentralized architecture is complex. Although the demand related to bandwidth and centralized processing is reduced greatly in such an architecture, it introduces latency between actuation and sensing phases and increases the challenges related to the sharing of misinformation.

Engineering Challenges in Designing ADAS Systems

ADAS technology development affects many parts of vehicle engineering. Vital requirements for future developments are:

- Increasing redundancy.

- Reducing weight and size of components (such as electronics, sensors and cameras).

- Assimilating exclusive functions into more comprehensive systems. Additionally, accomplishing more multifaceted ADAS functions involve not only input from more cameras and sensors but also the fusion of data from those sensor elements.

Redundancy

Increasing automation and (semi-)autonomy in vehicles increases the importance of the reliability of automotive electronics both at the system- and component level. Therefore the concept of dual redundancy of key systems has been introduced to improve reliability and safety. For instance, in the event of failure of part of a vehicle’s ADAS system you still need to be able to control the steering and brakes; a so-called limp home mode. Examples of systems that need redundancy are: drive by wire, steering, and braking systems.

To achieve hardware redundancy extra components are included, which allow the continuing operation of a system in the event of a partial failure, thus increasing the availability and reliability of the system. Take for example a traditional brushless motor with three phases; if one of these phases is lost, then the motor will fail to turn. However, if the motor is designed to have another 3-phase set of windings, then if one phase fails, the motor will still operate.

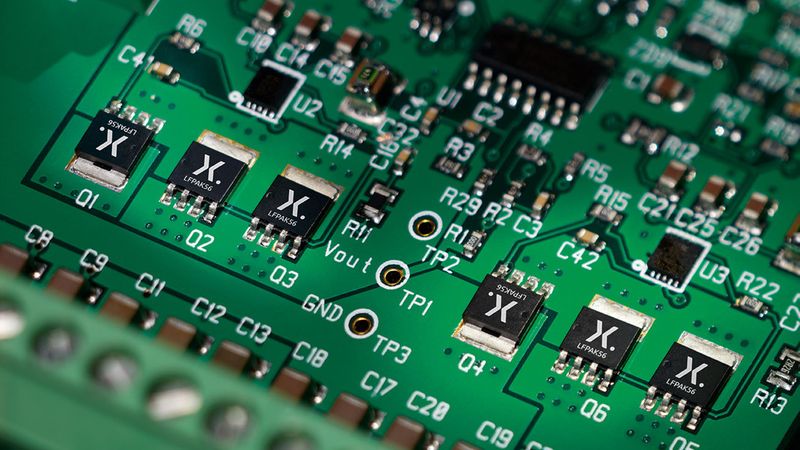

The requirements for high levels of system availability are driven by standards such as ISO26262 for critical safety functions where Automotive Safety Integrity Level (ASIL) C or D is required. Modern mission-critical automotive systems now feature redundancy and high-reliability automotive power MOSFETs that adhere to AEC Q101 qualifications from the Automotive Electronics Council.

Increased safety and reliability are great. However, dual redundancy has the potential to increase the size, weight, and complexity of electronic subsystems, which already have become bigger, heavier, and more complex with an increasing amount of ADAS systems.

Semiconductor manufacturers are innovating to overcome these challenges around the weight, size, and reliability of their components. Examples of solutions are MOSFETS with two independent channels inside a compact footprint, enabling both space and weight savings for designers.

A future article in this series will particularly address reducing the size of electronic components by the use of automotive qualified highly reliable small size Discrete Flat No Leads (DFN) packages.

Interference

Along the same lines, another important concern is related to interference and shortcuts. The automotive software industry must meet the strict safety requirements and follow the proper certifications to ensure that everything is going as intended. Freedom from interference is an important requirement. The electronic currents passing through a component of an electronic system should not impact a nearby component through interference.

Besides adhering to standards and qualifications, something called Failure Mode and Effects Analysis (FMEA) can play an imperative role in discovering potential failures and studying their impact. FMEA can be an extremely powerful tool to lessen the error rate in an automotive system and to recognize the underlying complications in any situation of failure.

Conclusion

ADAS systems have tremendous potential to increase the safety, comfort, and effectiveness of our vehicles and transportation systems. By many ADAS is seen as a stepping stone to fully autonomous vehicles.

As we’ve seen, more systems and more advanced systems, increase weight, seize, and complexity both on a systems level as well as on the overall vehicle architecture level. Semiconductor companies are responding to above mentioned challenges by innovating their components. The technological expertise of semiconductor companies is more impactful than ever in the future development of vehicle autonomy.

This article is written by Ahmed Faizan Sheikh and co-authored by Ian Kennedy and Wayne Lawson.

This article is part of a series about ADAS and Autonomous Vehicles, sponsored by Nexperia. In the next articles we will dive more deeply into the new semiconductor technologies that reliably enable you to bring high-performance computing, 5G connectivity, and sensing into cars. The second article will dive into how new semiconductor products can increase reliability and performance in electrical automotive systems. It's called “Putting high-performance computing into cars – automotive highly reliable miniaturized Discretes for autonomous driving” and written by Jan Birger Preibisch.

More articles on autonomous vehicle technology can be found here.

To read more about how the electrification of cars' powertrains impact semiconductors; read this article by Ian Kennedy.

References

• Advanced driver-assistance systems: Challenges and opportunities ahead - Mckinsey & Company

• ADAS radar sensor module design - Nexperia