Generative Design in Engineering: Two Different Approaches

Generative design is getting a lot of attention in the world of engineering, but what is it exactly? Here we explain how generative design can add value to your engineering process and why you should probably avoid the popular "black box" approaches.

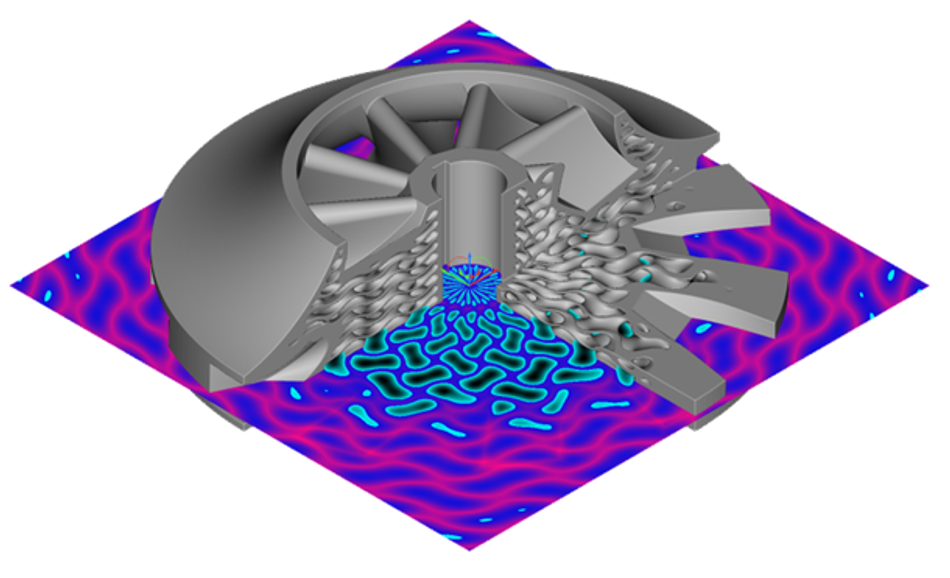

Topology optimization is a great tool for lightweighting, but generative design can offer much more. Source: nTopology

What is Generative Design?

Generative design is an emerging engineering design methodology that combines elements from CAD, multiphysics simulations, and computer science.

Since it touches upon so many different disciplines, concisely defining what exactly generative design is can be challenging. Here’s the one that I prefer:

“Generative design is a goal-driven, computational design methodology. Generative design software equips engineers with digital tools that enable them to explore a large design space effectively and efficiently and converge quickly to the best possible solution.”

For engineering design, the outcome of a generative process is typically a component with an optimized geometry that meets high-level design requirements.

These can be either technical — such as strength, stiffness, weight, manufacturability, and cost — or non-technical — like aesthetics, serviceability, recyclability, consistency with design standards and organizational procedures, or compliance with the regulations of different countries.

Let’s explore further the key elements of the generative design process.

Generative design is goal-driven

In this sense, generative design is not much different than the traditional iterative engineering design process. It begins by creating a minimal set of high-level design constraints and objectives. The main distinction is the emphasis that is put on the problem definition phase. Defining the available design space clearly is critical to obtaining a usable result.

Generative design is computational

In generative design, the geometry is created by an algorithm and not directly by the designer. Simulations are at the core of practically every generative process. This means that generative results are partially validated — of course, a detailed analysis is necessary for mission-critical components. This high degree of automation allows the exploration of a wider design space faster and more effectively than ever before.

Generative design is a digital tool

In essence, generative design is a deeply collaborative activity between the designer and the software. The outcome of most generative design algorithms is merely a solution proposal — not an engineered product. Several steps and iterations are needed to further explore, refine, and validate these results. Of course, by combining the expertise that seasoned engineers have built over the years with the power of these digital tools, you can create solutions that were previously impossible.

The Value of Generative Design

The intrinsic value of generative design is that it flips the traditional model of first creating and then evaluating a geometry. Instead of asking, “does this shape meet my requirements?”, an engineer following a generative approach asks, “what is the shape that best meets my requirements?”

Generative design is a tool that unlocks rapid engineering innovation. If used correctly, it can help your business unlock new opportunities for rapid engineering innovation. More specifically, generative design can:

Accelerate your product development cycles by automating manual engineering design and verification tasks

Lead to the development of better products as it produces unbiased solutions that may not immediately be obvious to a human designer

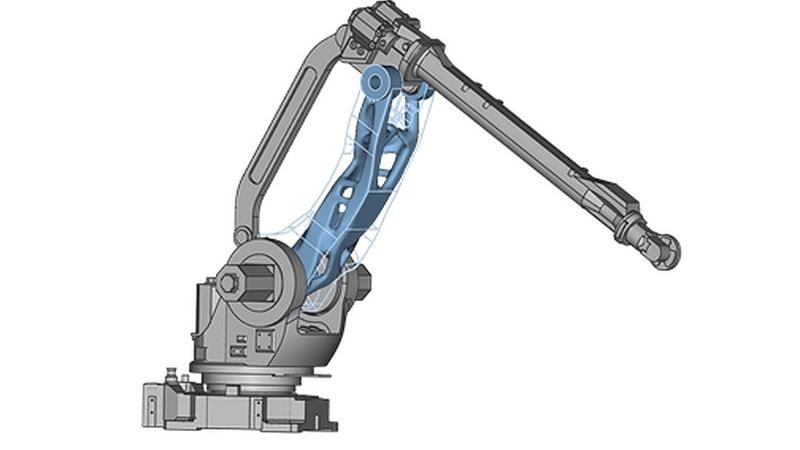

Enable you to take full advantage of advanced manufacturing technologies, such as additive manufacturing or any other robotic or digital manufacturing process

The Traditional “Black Box” Paradigm

It may surprise you that most “generative” tools today are based on the same methodology: topology optimization; a simulation-driven approach first developed back in the ’80s.

Topology optimization is a powerful tool that can generate new concepts during the early stages of the design process, but it has certain practical limitations that hinder its wider use in real-world applications of generative software that are based on it.

Topology optimization is very sensitive to the inputs that you give it.

Even a small change in a parameter or input can make a huge difference to the produced “optimum” result. You can see this in action in a recent nTop Live by our application engineers or in this presentation by one of the pioneers of topology optimization.

AI-powered solutions are not as good as they may seem.

So, you may think: “let’s use machine learning to predict what values will produce the best results.” This is the approach that many software vendors followed. But there is a big caveat: the burden of evaluating a design still falls on the engineer. Design evaluation and validation is a complex process and contemporary AI tools cannot perform such complex tasks.

Engineers do not work using “black box” approaches.

The standard approach to generative design seems to be this simple three-step approach: 1) specifying objectives and constraints, 2) wait for the algorithm to generate solutions, and 3) select the best option. In my experience, engineers do not work this way. Engineering design is characterized by multiple iterations and frequent change. It is much more complex than what can be captured by a generic workflow.

An Alternative Approach to Generative Design

Here’s the idea in a nutshell: instead of following the steps that someone else built for you, create your own generative design workflows. This approach enables you to incorporate specific engineering knowledge that already exists in your team while gaining all the other benefits of generative design.

nTop Platform is a generative design software that gives engineers direct and predictable control over every aspect of the process and its outputs. We built our software so that you can adjust it to your engineering workflows — not the other way around.

To tackle the limitations of traditional modeling technologies, we built nTop Platform on an unbreakable implicit modeling engine. This is a technology we pioneered for mechanical engineering applications. It is fast, robust, and can easily handle geometries with high levels of complexity.

To help you create reusable and standardized engineering design processes, we created a platform where built-in and user-created capabilities seamlessly merge into reusable workflows. This way multiple engineers can collaborate to build systems that encapsulate core engineering knowledge, manufacturing methodologies, and your in-house IP. Then lock them and share them with the organization to scale-up.

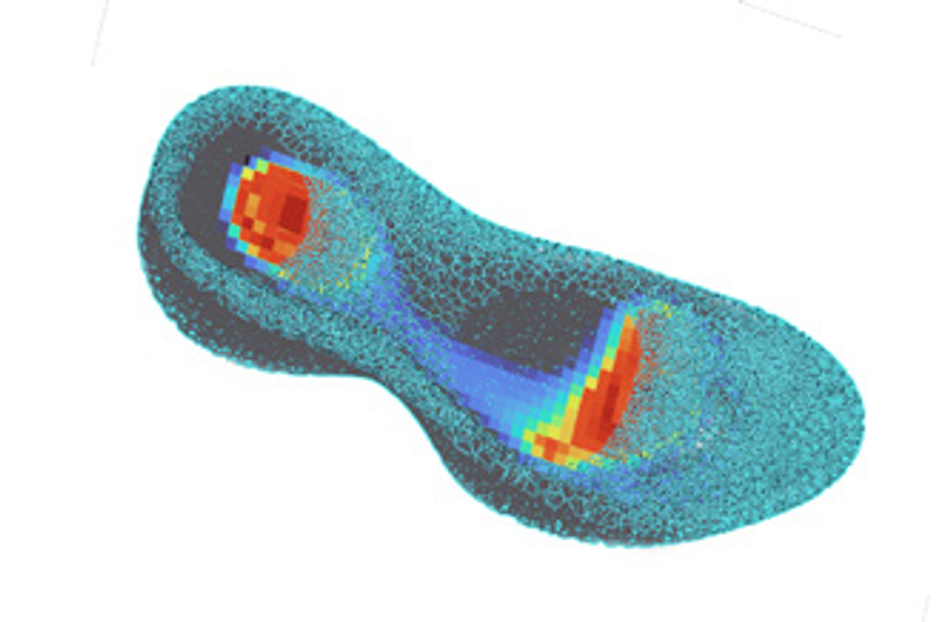

To enable you to go beyond topology optimization, we developed a generative design methodology we call Field-Driven Design. By superimposing different fields — including, complex geometry, simulation results, or experimental data — you can create unique, optimized, and high-performing structures.

If you want to learn more about our approach, we wrote a Guide to Generative Design that is now available for download.

Key takeaways

Generative design is a computational approach to engineering that uses algorithms to create part geometry.

The practical value of generative design is that it can greatly speed up your engineering process and allow you to explore a wider design space.

The traditional “black box” approaches that are based on topology optimization are foreign to that way that engineers work.

nTop Platform gives you an alternative approach to generative design by giving you complete control over the whole process.