Digital Twins for a Sustainable Future: A Blueprint for Resource Efficiency Across Industries

Explore how Siemens digital twin technology drives sustainability, decarbonization, and resource efficiency across manufacturing, buildings, energy, and aerospace through real-time simulation.

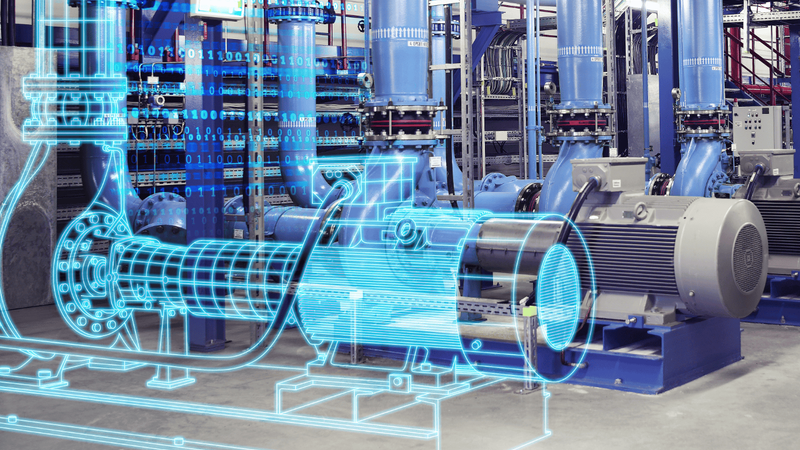

Global resource consumption is projected to increase by at least 60% by 2060, placing unprecedented strain on industries to innovate and operate sustainably [1]. Amid rising energy costs, tightening regulatory frameworks, and shifting market expectations, companies are seeking technologies that can reduce emissions, optimize resource utilization, and build resilience into their operations. Digital twin technology offers an effective solution as a dynamic method of linking the real and the digital worlds to enable accurate modeling, simulation, and real-time optimization. Digital twins enhance decision-making across the value chain, helping businesses meet their sustainability targets while improving efficiency and adaptability.

They empower organizations to anticipate disruptions, refine performance, and enable real-time improvements without interrupting live operations. Through advanced simulation, continuous feedback, and actionable insights, digital twins are redefining how businesses achieve decarbonization and operational excellence.

Sustainable Transformation Through Siemens’ Integrated Digital Twin Ecosystem

While many companies are turning to digital twin technology to optimize performance and reduce emissions, results often fall short without full integration across systems, data sources, and lifecycles. In most operations, a lack of real-time data flow creates blind spots and delays, leading to inefficiencies, downtime, and stalled progress on decarbonization goals.

Siemens addresses these challenges with a unified digital twin ecosystem built on end-to-end integration. Unlike fragmented solutions that replicate only part of a process or lifecycle, Siemens offers a continuous digital thread that connects the entire value chain, from concept and design to production, operation, and service. This integration of dynamic, real-time virtual representations across every stage supports traceability, quality assurance, and rapid iteration.

At the core of this ecosystem is Siemens Xcelerator, an open digital business platform that accelerates digital transformation and enables customers to unlock value faster. The key components of this ecosystem include:

NX™: Enables precise product design with seamless iteration between design and simulation, reducing development time and waste

Simcenter™: Simulates and optimizes product performance under real-world conditions, cutting physical prototyping and supporting sustainable designs

Teamcenter®: Manages product data, version control, and collaboration, ensuring compliance, quality, and efficiency across teams.

IT, OT, and IoT Integration: Connects digital twins with enterprise and operational systems for full visibility, predictive maintenance, and adaptive performance.

This level of integration helps organizations:

Eliminate silos and streamline data flow across departments and processes

Make faster, data-driven decisions with confidence

Minimize material waste, energy consumption, and carbon emissions through predictive and optimized processes

Enhance product quality, operational reliability, and customer satisfaction

By weaving together real-world data and advanced simulation, this integrated digital twin ecosystem equips businesses across discrete and process manufacturing, buildings, and energy systems with the tools and insights needed to drive decarbonization, efficiency, and competitiveness.

Real-World Applications of Siemens’ Digital Twins

Digital twins combine simulation, real-time data, and continuous learning to help organizations design, test, and optimize systems before committing physical resources. From individual components to entire facilities, virtual modeling eliminates trial-and-error on the shop floor, reduces waste, and accelerates innovation.

By linking product and production lifecycles and integrating with supply chains, digital twins like those enabled by Siemens’ ecosystem deliver measurable results, including operational agility, lower emissions, and improved productivity. These outcomes are already being realized in a wide range of application areas:

Manufacturers simulate complex machine kinematics and cooling airflow designs before investing in physical assets.

Shop floors are optimized using digital twins to determine ideal AGV routes and material flows.

Plant layouts are validated virtually after evaluating thousands of possible configurations.

Real-time operational data combined with AI further enhances decision-making by predicting and optimizing future production scenarios, while closed-loop feedback continually informs next-generation designs.

These advanced capabilities translate directly into impact, supporting decarbonization, operational excellence, and resilience across sectors such as additive manufacturing, commercial buildings, and aerospace. Digital twins are equally impactful in process industries, where platforms such as Siemens’ COMOS and Simatic PCS neo connect plant design, automation, and operations into a continuous model [2]. By simulating process behavior and energy use, they help companies reduce waste, improve safety, and accelerate sustainable production in sectors such as chemicals and food & beverage.

Additive Manufacturing: Driving Flexibility, Sustainability, and Innovation

Additive manufacturing (AM) is a powerful application of digital twin technology. By embedding digital twins into every stage of the AM value chain, companies can reduce material waste, accelerate development cycles, and create high-performance, sustainable products. This approach supports both agile production and environmental goals.

For instance, Siemens’ end-to-end digital thread allows companies to design and simulate mold production in a single software environment, cutting material use by up to 88% and reducing tooling time by 25%. Digital twins enable precise simulation and 3D printing of molds with minimal waste, making it easier to recover and recycle leftover materials. In sectors like aerospace and automotive, lightweight AM components reduce energy consumption over a product’s lifecycle, while localized spare parts manufacturing supports circular economy goals and minimizes supply chain emissions.

One compelling example of this transformation is the Electroimpact Scalable Composite Robotic Additive Manufacturing (SCRAM) system, a six-axis, continuous fiber-reinforced 3D printing platform developed for aerospace applications. Controlled by Siemens’ SINUMERIK ONE, a next-generation CNC control system with integrated digital twin capabilities, SCRAM enables precise simulation and optimization of layer-by-layer deposition. This setup allows engineers to tailor fiber orientation for maximum strength and stiffness while minimizing errors, material waste, and lead times [3].

This level of digital twin-enabled control extends beyond aerospace. Ingersoll leveraged SINUMERIK ONE to develop the world’s largest thermoplastic 3D printer, capable of producing large-scale industrial components on-site. By reducing the need for transportation and reinforcing supply chain resilience, this innovation supports more sustainable and flexible manufacturing models.

Siemens’ AM solutions are also making a healthcare impact. Unlimited Tomorrow uses Siemens’ digital twins to produce lightweight, cost-effective prosthetic arms for children. Virtual simulations optimize fit and functionality, reducing development time and material usage while delivering tailored solutions for individuals.

Beyond individual examples, Siemens’ strategy emphasizes the seamless integration of traditional and additive manufacturing. The Additive Manufacturing Experience Center (AMEC) brings this vision to life, showcasing how Siemens’ AM technologies drive mass customization, flexible batch production, and sustainability.

To accelerate adoption, Siemens extends its ecosystem through the Xcelerator Marketplace, partnering with companies like Castor, EOS, and AMbitious to offer scalable, interoperable solutions. This collaborative model empowers companies to harness AM as a strategic driver of resilience, productivity, and sustainability.

Commercial Real Estate: Turning Complexity into Sustainable Advantage

Commercial real estate is facing mounting pressures: energy costs are surging, regulatory expectations around carbon reduction are tightening, and market shifts like rising vacancy rates are forcing owners to rethink operations. Many buildings are still managed with fragmented systems that limit real-time visibility, resulting in inefficiencies, higher emissions, and reactive maintenance.

Siemens offers a path forward with its Building X Lifecycle Twin, a digital twin solution for buildings and infrastructures that integrates dynamic and static data across the entire building lifecycle. By merging data from Building Information Modeling (BIM), Building Management Systems (BMS), Computerized Maintenance Management Systems (CMMS), and IoT devices, Building X Lifecycle Twin creates a connected, digital replica of the building. This offers real-time performance insights and visualizations that support operational efficiency, proactive maintenance, and sustainability reporting [4].

A key strength lies in the synergy of BIM and Building Twin. BIM provides a detailed digital foundation, containing up to 95% of the information needed for a comprehensive Building Twin. This embeds rich design, construction, and operational data into a single, collaborative model, extending seamlessly into building operations. The Building Twin draws on real-time data to provide a live view of the building’s performance. Therefore, design adjustments can be tested, and systems can be commissioned before implementation, resulting in efficiency gains and cost savings.

A clear illustration of this approach can be found in modern smart office developments. At Gioia 22 in Milan, Siemens supported the transformation of a former office tower into a high-performance smart building. By integrating design, operational, and real-time building data into a unified digital environment, the project achieved a 75% reduction in energy consumption compared to similar towers and saved 2,260 tons of CO2 annually. The result is a commercial asset designed for long-term efficiency, transparency, and sustainability [5].

This lifecycle-driven approach is equally relevant for corporate headquarters aiming for Net Zero operations. At FUNKE Mediengruppe in Germany, Siemens connected more than 12,000 data points across building systems to enable centralized monitoring, remote services, and energy optimization. By creating a consistent digital view of building performance, facility teams gain the visibility needed to reduce operational costs and maintain comfortable working environments, directly supporting the company's decarbonization targets [6].

The Siemens ecosystem further strengthens this value proposition. Through partnerships such as Pointr, Siemens adds advanced indoor positioning and location intelligence that helps building owners understand how spaces are actually used [7]. These insights support smarter space planning, wayfinding, and workplace services — capabilities that are increasingly essential as hybrid work and fluctuating occupancy reshape the economics of commercial real estate.

These capabilities also extend to the hospitality sector, where smart hotel solutions balance guest experience with operational rigor. By integrating room automation with property management systems, hotels can personalize comfort for guests while automatically curbing energy usage when rooms are vacant, ensuring sustainability targets are met without compromising service quality [8].

Taken together, these examples show how digital twins at the building and portfolio level help commercial real estate owners turn operational complexity into a sustainable advantage. By connecting lifecycle data, real-time performance insights, and human-centric use cases, Siemens enables offices and other commercial properties to operate more efficiently, meet decarbonization goals, and remain attractive in a competitive market.

Aerospace: Accelerating Innovation and Sustainability through Digital Twins

Aerospace manufacturers are improving how they design, build, and certify aircraft by embedding digital twins into every stage of development. From simulation to design, production, and operations, integrating digital solutions creates a continuous digital thread that connects engineering, manufacturing, and certification workflows. This seamless integration drives faster innovation, reduces environmental impact, and ensures compliance with stringent airworthiness standards.

At the heart of this transformation is the model-based systems engineering (MBSE) approach, which enables multidisciplinary teams to collaborate effectively from the earliest design stages. By leveraging comprehensive digital models, companies can optimize system architectures, validate design assumptions, and identify potential issues long before physical testing. For example, organizations like Bye Aerospace have achieved up to a 66% reduction in engineering resources and significantly accelerated development timelines for electric aircraft [9].

Siemens’ digital twin technology also reshapes the certification process, traditionally a bottleneck in aerospace programs. By integrating compliance requirements into design workflows and enabling traceability across development phases, companies such as Fokker Services and Lisa Airplanes have reduced certification cycle times and costs. Virtual verification and certification allow teams to identify problems early, minimizing reliance on expensive physical testing and enabling a smoother path to market.

On the production floor, Siemens’ smart manufacturing solutions transform factories into connected, adaptive environments. Model-based planning, virtual validation, and closed-loop optimization ensure right-first-time production while reducing commissioning times by up to 60% [10]. Companies like Ingersoll and Broetje-Automation leverage Siemens’ digital twin-powered automation to enhance machining precision, improve throughput, and maintain consistent quality even for complex aerospace components.

Digital twin technology also supports sustainability goals. By simulating materials performance, optimizing weight, and enabling more efficient resource use, Siemens helps aerospace manufacturers reduce energy consumption, lower emissions, and improve supply chain resilience. Integrating digital twins with AI, edge computing, and industrial 5G further enables fast adaptation to market shifts and regulatory demands.

From Digital Twins to the Industrial Metaverse

Digital twins have moved from proof-of-concept to the frontline of operational excellence. They shape how industries design, produce, and operate more efficiently and sustainably. By enabling predictive insights and operational optimization, they bridge the gap between strategic goals and measurable outcomes.

But this is just the beginning! The industrial metaverse, built on digital twins, IoT, and AI, is emerging as the next frontier, offering immersive, physics-based simulations that can transform how businesses innovate, collaborate, and respond to challenges. The question for every business is not when but how to embrace this digital evolution.

References

[1] “Transforming industries with digital twin technology,” Siemens. [Online]. Available: siemens.com/global/en/company/digital-transformation/digital-twin

[2] “Comos – Making data work.” Siemens. [Online]. Available: siemens.com/global/en/products/automation/industry-software/plant-engineering-software-comos

[3] “Electroimpact SCRAM system sculpts new possibilities,” Siemens. [Online]. Available: siemens.com/us/en/products/automation/systems/sinumerik-cnc/machine-tools/sinumerik-one/electroimpact-scram-case-study

[4] “Building X - Lifecycle Twin,” Siemens. [Online]. Available: xcelerator.siemens.com/global/en/products/buildings/building-x/solutions/applications/lifecycle-twin

[5] “From Ruin to Revolution: The Rise of Gioia22,” Siemens. [Online]. Available: siemens.com/global/en/products/buildings/references/coima-gioia22

[6] “Media company of the future – the headquarters of FUNKE in Essen,” Siemens. [Online]. Available: siemens.com/global/en/products/buildings/references/funke-mediengruppe

[7] “Transform Corporate Real Estate: Smart Offices,” Siemens. [Online]. Available: xcelerator.siemens.com/global/en/industries/commercial-buildings/smart-office

[8] “Smart hotels of the future,” Siemens. [Online]. Available: xcelerator.siemens.com/global/en/industries/commercial-buildings/smart-hotels

[9] “Airplane manufacturer uses Siemens solutions to reduce product development time for all-electric composite aircraft,” Siemens. [Online]. Available: resources.sw.siemens.com/en-US/case-study-bye-aerospace

[10] “Smart manufacturing solutions for aerospace and defense,” Siemens. [Online]. Available: sw.siemens.com/en-US/digital-thread/smart-manufacturing/aerospace-manufacturing