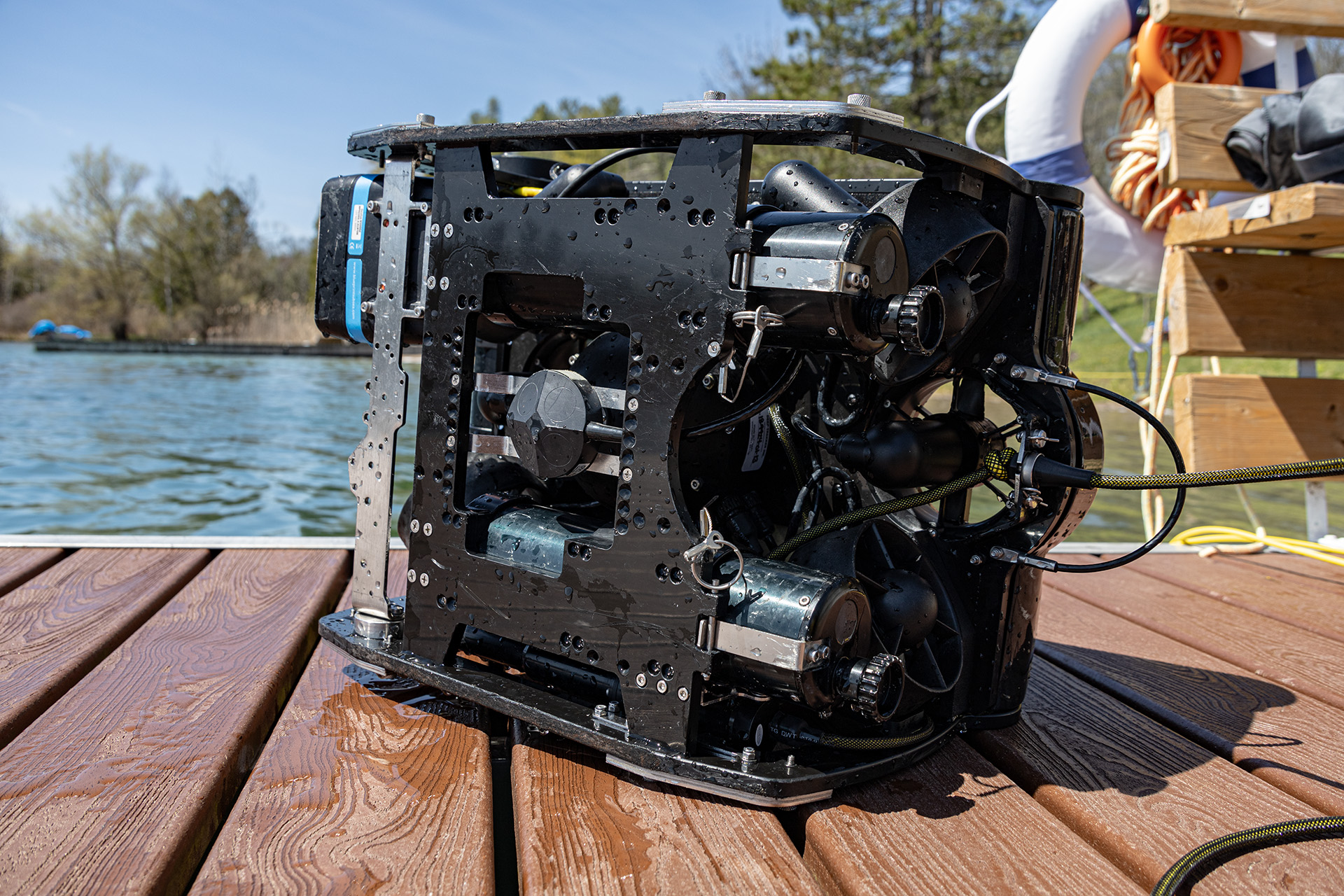

Deep Trekker IMU Testing: A Detailed Look at MEMS and FOG Technologies

Discover how Deep Trekker rigorously tests and evaluates IMU technologies, comparing MEMS and FOG systems to ensure precise underwater navigation for ROVs.

Operator viewing screen on ROV handheld controller.

This article was first published on

www.deeptrekker.comThe application of advanced sensors and navigation methods in Deep Trekker ROVs are utilized across a broad range of industries, including marine research, search and recovery, underwater inspection, aquaculture, offshore infrastructure maintenance, and environmental monitoring, to name a few.

With reliable positioning and navigation in complex underwater environments, Deep Trekker ROVs allow engineers, scientists, and business owners to conduct underwater operations with efficiency, accuracy, and reliability.

Deep Trekker employs a suite of advanced sensors and methods to overcome the challenges of underwater navigation, enabling true underwater positioning. In this article, we explore the various types of sensors utilized by Deep Trekker, their performance comparisons, testing methodologies, and ongoing advancements in underwater navigation technology.

Deep Trekker IMU Testing and Evaluation

In our pursuit of refining underwater navigation, Deep Trekker has rigorously evaluated a spectrum of positioning systems, examining their operational complexities and real-world performance. Nemanja Kliska, Deep Trekker Team Lead and Autonomy Systems Engineer, provides insights into the nuanced distinctions between these systems, describing their functionalities and inherent trade-offs.

Navigating this intricate landscape, Deep Trekker has meticulously curated an optimized solution, fusing the DVL with the IMU to strike a delicate balance between cost-effectiveness and performance.

This approach mirrors market leaders, though at a fraction of the cost, thus democratizing access to cutting-edge positioning technologies.

How Does the Deep Trekker System Compare to FOG IMUs?

Aside from the exorbitant price point of FOG IMUs compared to the much more affordable MEMS, a crucial distinction lies in the impact of magnetic interference on heading stability.

Kliska notes, "While both MEMS and FOG IMUs offer accurate Dead Reckoning, FOG IMUs do not utilize a compass and therefore excel in environments with significant magnetic interference, such as near metal wrecks or ships. Their stability remains unaffected, ensuring precise navigation even in challenging conditions."

Another significant operational distinction is the pre-mission preparation required for FOG IMUs. Prior to starting a mission, FOG IMUs necessitate initialization on land, where they must remain stationary on stable, flat ground for a period typically ranging from 10 to 15 minutes.

This initialization process cannot be conducted aboard a vessel. This requirement highlights the need for careful planning and consideration of environmental factors when deploying FOG IMUs, contrasting with the more flexible deployment options offered by systems like Deep Trekker’s Dead Reckoning implementation with observation class ROVs.

Underwater Navigational Challenges and Solutions

Deep Trekker's navigation systems encounter diverse environmental factors, necessitating adaptive solutions. Kliska explains, "In scenarios like ship hull inspections, where magnetic interference is inevitable, MEMS IMUs, though prone to magnetic noise, provide flexibility and rapid deployment, making them ideal for dynamic applications." Deep Trekker has also developed different modes for its ROVs that can be switched in real-time to address and navigate issues arising from magnetic interference.

Kliska adds, “It’s also important to note that we have found that most of the magnetic interference happens near the engine room of the ship, allowing us to cover inspections of 95% of the submerged portions of the vessels virtually unaffected.” For the remainder, switching modes allows the ROV to continue the inspection without being affected by ferrous environments.

In this context of ship hull inspections, where precise navigation amidst magnetic interference is critical, MEMS IMUs provide a practical solution. Their ability to adapt to varying magnetic fields while maintaining agility and responsiveness enables effective maneuvering around obstacles and complex structures. This adaptability ensures that Deep Trekker's navigation systems remain effective and reliable, even in challenging maritime environments where magnetic interference is present.

By leveraging MEMS IMUs, Deep Trekker ROVs navigate through intricate underwater environments with agility and precision, allowing tasks such as ship hull inspections to be carried out efficiently and accurately. Despite the inherent challenges posed by magnetic interference, the flexibility and rapid deployment capabilities of MEMS IMUs ensure that Deep Trekker's navigation systems remain the ideal solution for underwater inspections and operations.

Testing Methodologies and Performance Evaluation

Deep Trekker employs comprehensive testing methodologies to validate IMU performance across various environments. Kliska outlines, "Our testing encompasses top-down validation, where ROVs navigate predefined courses to assess performance. Additionally, our bottom-up analysis involves analyzing sensor specifications and dynamic performance to refine our Sensor Fusion algorithms."

Top-down validation constitutes a cornerstone of Deep Trekker's testing approach. Within this framework, ROVs are tasked with navigating predefined courses, serving as real-world proxies to evaluate IMU performance under operational conditions. This methodological approach offers a holistic perspective, allowing Deep Trekker to explore the IMU's performance in scenarios mirroring actual field deployments.

In parallel, bottom-up analysis forms an integral component of Deep Trekker's testing regimen. This analytical process requires a meticulous examination of sensor specifications and dynamic performance parameters. By exploring the intricacies of sensor behavior and responsiveness, Deep Trekker refines its Sensor Fusion algorithms, which serve as the bedrock for integrating data from multiple sensors to improve accuracy and reliability.

Ensuring Reliability Through Real-World Validation and Customer Collaboration

Kliska emphasizes the importance of real-world validation, stating, "In addition to in-house testing, we engage with customers to address specific challenges encountered in diverse environments. For instance, mitigating issues like depth-dependent error propagation in deep-sea operations requires tailored solutions and continuous refinement."

In deep-sea operations, errors can amplify with increasing depth due to environmental pressures and other factors. Addressing such issues requires more than just standard testing procedures; it necessitates the development of tailored solutions that are finely tuned to the unique conditions of deep-sea environments. This involves continuously refining algorithms and system components to ensure dependable performance at depths.

Engaging with customers allows Deep Trekker to gather valuable feedback and insights from actual field operations, which is instrumental in identifying areas for improvement and innovation. By integrating customer experiences and specific use-case scenarios into the development process, Deep Trekker can create more robust and effective solutions that are precisely aligned with the practical demands of underwater exploration and inspection.

In essence, ensuring reliability in challenging environments is an ongoing process that blends rigorous testing with real-world application and customer collaboration. This dynamic approach enables Deep Trekker to not only meet but exceed the expectations of performance and reliability in some of the most demanding and unpredictable underwater environments.

Deep Trekker’s Advancements in Sensor Fusion Algorithms

Deep Trekker places a high priority on the stability of its algorithms and the redundancy of its sensors to enhance the reliability of its navigation systems. Kliska elaborates on the advancements in their Sensor Fusion algorithms, highlighting how these improvements are pivotal for maintaining accurate and stable navigation in challenging underwater environments.

"Our Sensor Fusion algorithms are designed to integrate data from a variety of sensors," Kliska explains. This integration process is dynamic, with the algorithms constantly recalibrating in real-time to ensure that the data remains stable and reliable, even as the conditions around the ROV change. This constant recalibration helps to smooth out any discrepancies or anomalies that might arise from individual sensor readings, leading to a more consistent and accurate navigational output.

Deep Trekker has also implemented robust recovery mechanisms within their systems. These mechanisms are crucial for maintaining operation in the event of a sensor failure. If one sensor experiences an issue or fails, the system can autonomously detect the problem and switch to backup sensors without interrupting the ROV's operation. This redundancy ensures that the vehicle can continue its mission seamlessly, providing a significant advantage in critical and time-sensitive underwater tasks.

Mitigating Magnetic Distortions and Startup Time

Drawing from empirical data, Deep Trekker's testing initiatives have unveiled inherent challenges, such as mitigating magnetic distortions that affect heading and accuracy. Nemanja recounts a ship hull inspection in Hamilton, ON, Canada, wherein deviations in reported heading necessitated manual compensations to align with actual trajectories, highlighting the nuanced calibration complexities inherent in mitigating magnetic disturbances. Deep Trekker addresses these challenges by employing Sensor Fusion algorithms designed to compensate for such errors.

Deep Trekker's commitment to user-centric design is evident in simplifying startup procedures, forgoing prolonged settling times characteristic of FOG based IMUs. By circumventing laborious calibration procedures and leveraging pre-calibrated sensor arrays, Deep Trekker expedites operational readiness, augmenting user convenience without compromising navigational integrity.

“Typically, a FOG IMU requires about 15 minutes of settling time and that's used to determine the sensor bias,” explains Kliska, “And so, with the higher end FOG based IMUs, you're required to put it on a flat, static surface where it's not moving while it's calibrating, so you can't start up on a boat. Then there's some other startup systems once you get in the water, you have to have DVL calibrate itself, so you have to move around until it gets a lock. Overall, it takes about 20-25 minutes of calibration before you can start running a mission.

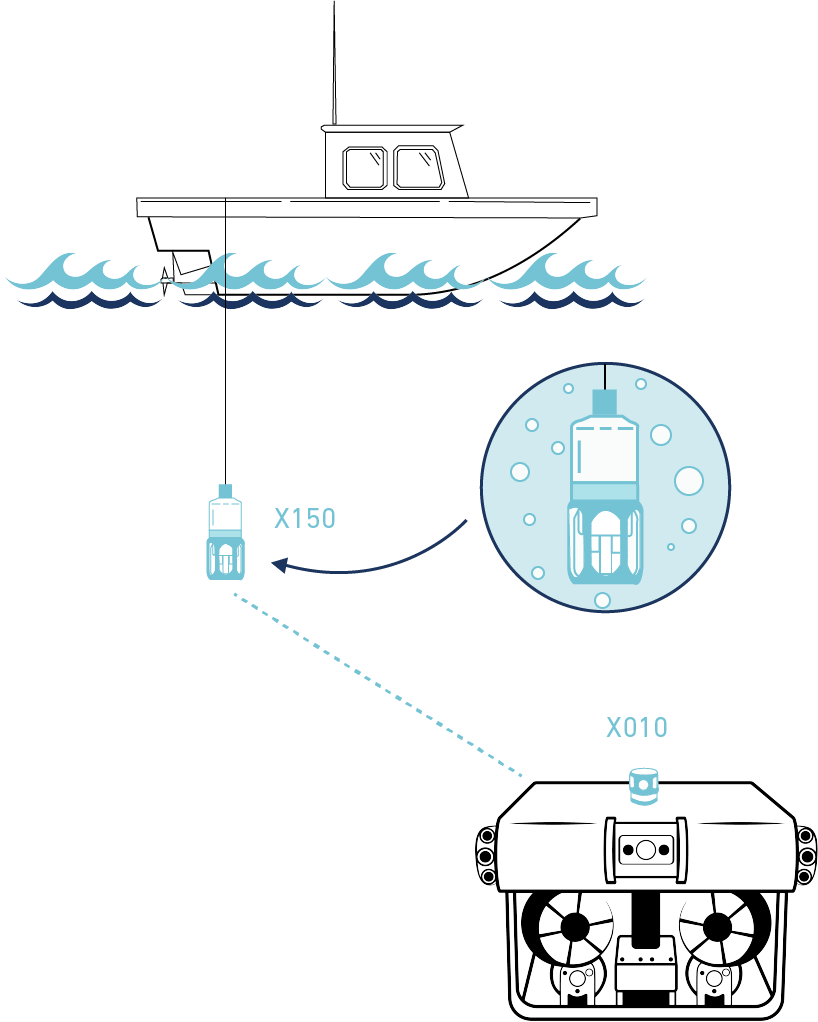

With the Deep Trekker system, you can deploy right away, and you can do that off a boat, too; you don't need to have it on the ground.”

Leveraging USBL and GPS Augmentation

To enhance Dead Reckoning methodologies, Deep Trekker explores the symbiotic integration of absolute position sources, defined by USBL and GPS systems. While USBL technologies offer exceptional precision in open water environments, their effectiveness is limited due to acoustic reflections and background noise, necessitating meticulous setup considerations to mitigate environmental constraints.

Conversely, GPS systems have robust global positioning capabilities, albeit confined to surface operations, thus necessitating seamless transitions to Dead Reckoning methodologies when submerged.

Deep Trekker's strategic use of MEMS IMU and DVL configurations, combined with USBL and ROV GPS integration, delivers a versatile positioning suite adaptable to diverse operational requirements.

Practical Validation and Future Prospects

In summary, the incorporation of advanced sensors and positioning techniques transforms underwater navigation with Deep Trekker ROVs. By integrating IMU, DVL, USBL, and other state-of-the-art technologies like Dead Reckoning, Deep Trekker ROVs offer groundbreaking precision and reliability in navigating challenging underwater environments.

Deep Trekker's dedication to pushing the boundaries of underwater technology positions them as leaders in the field, offering pioneering solutions for underwater inspections and research. Continuously redefining the capabilities of underwater navigation, Deep Trekker is opening new avenues for exploration and innovation in marine industries while laying the groundwork for future discoveries and advancements.