Building a 720 kW Centralized Power Solution for Horticulture Lighting: A Case Study by Sager and MEAN WELL

A centralized 720 kW power system built with MEAN WELL's SHP-10K power supplies and engineered by Sager Electronics delivers high-efficiency, low-maintenance performance for a horticultural facility running 720 LED lights per room, simplifying control, scaling reliably, and minimizing heat.

Executive Summary

A large-scale horticultural grower in Florida needed a high-efficiency power delivery system to support 720 LED grow lights across multiple climate-controlled rooms. Their existing setup was overcomplicated, thermally inefficient, and prone to firmware and hardware issues. To address these challenges, Sager Electronics delivered a modular, rack-mounted power solution using MEAN WELL 72 SHP-10K high-efficiency AC-DC power supplies. Each unit provides 10 kW of clean, centralized power with a total system output of 720 kW per room. The result was a simplified, maintainable, and thermally optimized infrastructure that reduced in-room heat loads while offering precise control over lighting cycles. The success of this deployment highlights the broader applicability of centralized power systems for high-density lighting environments in industries such as vertical farming, retail, and industrial automation.

Introduction

A large horticultural grower in Florida was expanding operations across a 500,000-square-foot facility designed for climate-sensitive indoor cultivation. Each grow room was equipped with high-powered LED lights, supporting intensive, high-density plant growth across multiple zones.

As the facility grew, so did the expectations placed on its electrical infrastructure. The team needed a lighting power system that could align with strict environmental standards, simplify ongoing operations, and scale efficiently with future room buildouts. This case study explores how Sager Electronics and MEAN WELL partnered with the grower to deliver a solution tailored to these evolving needs.

The Challenge: Heat, Complexity, and Control in a Regulated Grow Room

The grower’s previous power setup introduced three major challenges: unnecessary system complexity, excessive thermal output, and insufficient control flexibility. The legacy solution featured firmware-controlled power systems with layered hardware and software dependencies. While technically capable, this approach far exceeded the functional requirements and introduced points of failure that led to instability, configuration issues, and difficulty in day-to-day operation.

Thermal performance was a more pressing concern. Though the LED drivers were located in a separate room, they generated substantial heat that affected auxiliary equipment and overall thermal stability within the area. This cumulative thermal load strained the control room’s Heating, Ventilation, and Air Conditioning (HVAC) systems, introduced reliability concerns, and increased energy usage.

Additionally, the customer required precise yet simple control over lighting intensity and timing, without the burden of managing complex digital protocols or firmware layers. The system needed to support basic functions such as dimming and remote ON/OFF capability, ideally in a way that could be grouped or replicated across multiple units.

These challenges had to be solved without increasing system footprint or introducing new layers of complexity. The grower needed a solution that was efficient, robust, and easily maintainable, with predictable, centralized behavior across hundreds of LED lights.

The Solution: A Modular, Centralized Power System Built With MEAN WELL SHP-10K

To replace the complex, heat-intensive legacy setup, Sager Electronics and MEAN WELL implemented a centralized, modular power architecture built around the MEAN WELL SHP-10K-380 power supply. This 10 kW AC-DC power unit offered the right combination of high efficiency, analog controllability, and robust construction, perfect for demanding, high-density lighting environments.

About the SHP-10K-380

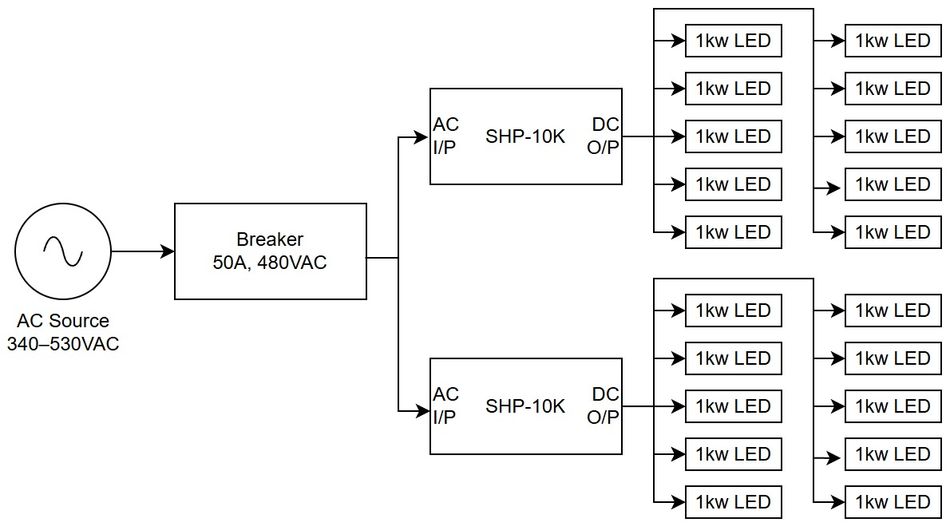

The SHP-10K-380 is a 3-phase, 10 kW power supply designed for applications requiring high reliability and thermal efficiency. It accepts 3-phase 340-530 VAC input and delivers a 380 VDC output at up to 96.5% conversion efficiency. The units are available in both forced-air and water-cooled variants; for this deployment, all 72 units were air-cooled, simplifying installation and long-term maintenance.

Feature | Description |

Input Voltage Range | 3-phase 340–530 VAC (480 VAC in this case) |

Output Voltage | 380 VDC (programmable) |

Max Power Output | 10 kW |

Efficiency | Up to 96.5% |

Cooling Type | Water-cooled, Forced-air (used in this deployment) |

Control Interface | Analog (0–5 V), Remote ON/OFF, CANBus, PMBus, Modbus RTU |

Built-in Protections | Over Voltage Protection (OVP), Over Current Protection (OCP), Over Temperature Protection (OTP), and Fan Failure Detection |

Communication Protocols | Optional Controller Area Network (CAN), PMBus, RS-485 (not used here) |

This system emphasized simplicity. Although the SHP-10K is capable of digital controls, no complex communication protocols (like CAN or PMBus) were used at the grower’s request. Instead, the SHP-10K’s analog input pins were used for precise dimming and ON/OFF control in grouped configurations.

System Architecture

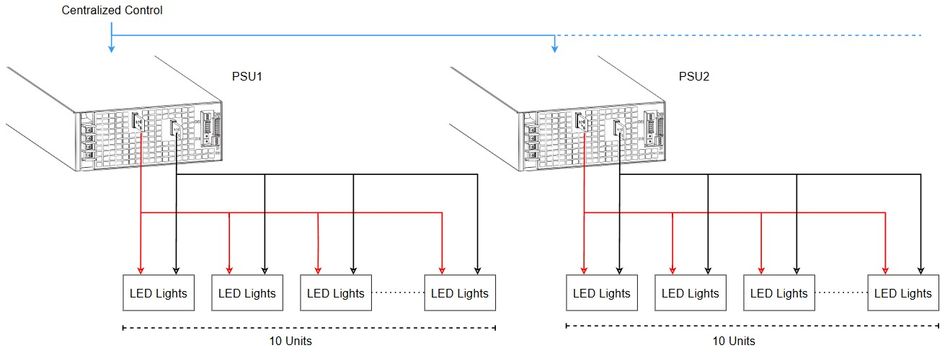

Each grow room was powered by 72 SHP-10K units, delivering a total of 720 kW. The layout was highly modular:

12 power supplies per rack, for a total of 6 racks per room

Each PSU powered a dedicated group of 10 LED lights

Each rack included a centralized remote ON/OFF and dimming control circuit wired in parallel across the 12 supplies

Wiring was streamlined using 10 AWG conductors, delivering DC power up to 500 yards from the racks to the lights

The power supplies were housed outside the grow rooms, eliminating excess heat inside the plant environment

This design offered clear advantages in modularity and reliability. If a power supply failed, it affected only 10 lights, just 1.4% of the total room. Maintenance could be done rack-by-rack, without shutting down the entire system.

Assembly & Deployment: From Off-the-Shelf to Field-Ready

While the SHP-10K is a high-efficiency off-the-shelf product from MEAN WELL, transforming it into a plug-and-play, field-deployable system for a high-power horticultural environment required thoughtful engineering and integration. That’s where Sager Electronics’ solutions team stepped in.

Sager’s Engineering Contributions

Sager Electronics didn’t just deliver power supplies, they delivered a complete, installable system optimized for both performance and ease of use. Their key contributions included:

AC Input Assembly Design: Sager engineered a custom AC input assembly that allowed the customer to leverage existing 50 A, 480 VAC breaker panels. Each breaker powered two SHP-10K units, reducing installation complexity and improving safety.

Rack Design and Power Distribution: The SHP-10Ks were mounted in standard 19-inch relay racks, with 12 power supplies per rack. Each rack included:

Pre-wired input/output connections

Front-facing LED indicators to display the operational status of each unit

A manual ON/OFF interface that allowed users to control all 12 units simultaneously

Busbar Modification for Field Installation: To simplify load wiring, Sager modified the SHP-10K output busbars by adding fixed studs, making it faster and safer to attach conductors in the field.

Custom Reusable Shipping Crates: To support phased deployment, Sager designed and built custom reusable crates, each capable of transporting six rack-ready units. Once unloaded, the crates were returned and reused, streamlining logistics and minimizing packaging waste.

Deployment Efficiency

Thanks to this thoughtful packaging and rack integration, on-site deployment was fast and consistent. The customer simply rolled each assembled rack into place, connected input power and load wires, and was ready to go. The systems remained on the casters, allowing them to be moved easily for maintenance or layout adjustments.

Compared to the previous over-engineered system with its software bugs, communication issues, and excess heat, the new solution was significantly easier to install, operate, and maintain. It enabled a smoother path from purchase order to full operation, without additional firmware programming or system-level troubleshooting.

Outcome & Benefits: Results from the Deployment

The centralized SHP-10K-based power solution delivered measurable improvements in thermal performance, operational simplicity, and system maintainability, exactly what the horticultural customer had been seeking.

Efficiency and Thermal Management

By replacing the legacy setup with 96.5% efficient SHP-10K units, the customer achieved a significant reduction in heat generation. While the previous system operated at around 90% efficiency, the 6.5% improvement translated to substantial energy savings and dramatically lower ambient temperatures, especially important given the scale of the deployment. With 720 kW of power delivered per room, even small improvements in efficiency had a large cumulative effect.

After the new system was installed, the room maintained a consistent, comfortable temperature, similar to walking into a climate-controlled 72-degree space, which was unimaginable with the previous setup.

Simplicity and Control

The customer had emphasized a preference for minimalism: no protocol stacks, no embedded firmware, no software updates. Sager and MEAN WELL delivered just that.

Each rack of 12 power supplies featured remote ON/OFF and analog dimming control, wired in parallel for simplicity.

Operators could manage light cycles with basic wall-mounted control systems, without relying on IT support or complex configuration tools.

The use of MEAN WELL’s built-in signal terminals enabled precise voltage trimming and current limitation through analog 0-5 V control signals, matching the lighting schedules and intensity needs.

Maintainability

The system’s modular design paid off immediately in day-to-day operations:

If one power supply fails, it only affects the 10 lights it powers. The rest of the room remains operational.

Spare SHP-10K units can be kept on-site and swapped in easily.

LED indicators on the front of each rack provide at-a-glance health status, reducing diagnostic time.

Scalability

Because each rack is self-contained and built with off-the-shelf components, the customer can easily replicate this architecture in new rooms or facilities. Expansion becomes a matter of ordering and installing pre-configured racks, not redesigning the system from scratch.

Return on Investment

The centralized system delivered measurable efficiency improvements and operational cost savings. These benefits compound across large-scale installations, making the investment highly impactful over time.

Lower heat = reduced HVAC strain and energy costs

Higher efficiency = less wasted power

Easier maintenance = reduced downtime and fewer labor hours

Simplified control = less training and fewer points of failure

Together, these factors deliver a high-value solution that meets the unique environmental and operational needs of horticultural facilities with high-density LED lighting infrastructure.

Collaboration & Engineering Synergy: Coordinated Efforts Behind the Project

Delivering a centralized 720 kW power system for a tightly regulated horticultural application required close coordination across multiple teams. This wasn’t just a product deployment, it was a system-level solution developed through collaborative engineering and iterative problem-solving.

Customer-Driven Requirements

The horticultural customer had clear priorities: reduce heat, avoid over-engineering, simplify control, and ensure maintainability. Their request for “dumb” power, without digital protocols or software dependencies, set the direction early. From there, Sager Electronics and MEAN WELL worked together to translate those needs into a deployable architecture.

Sager’s Role in Integration

Sager Electronics’ Custom Solutions Center took ownership of system integration. Beyond product selection, Sager’s engineers:

Designed custom AC input assemblies to align with the customer’s existing 480 VAC breaker panels

Modified output busbars with fixed studs to make field wiring easier and faster

Built racks with status indicators and manual control interfaces for all 12 PSUs in each rack

Developed reusable shipping containers to streamline logistics and reduce waste

These enhancements ensured the SHP-10K units weren’t just powerful, they were practical for real-world deployment at scale.

MEAN WELL’s Product Support

MEAN WELL provided technical insights on the SHP-10K platform, confirming performance ranges, operating characteristics, and best practices for analog control. Their support helped ensure the system design would deliver the expected thermal and electrical performance under real load conditions.

Joint Execution and Iteration

Sager and MEAN WELL also collaborated directly with the LED manufacturer to ensure compatibility between the SHP-10K and the lighting hardware. This involved aligning voltage, current, and control interface specifications so the fixtures could operate reliably and efficiently with the centralized power system.

Throughout the process, the three parties - customer, Sager, and MEAN WELL, met regularly to align on specifications, validate mechanical and electrical interfaces, and resolve edge-case challenges. This cross-functional collaboration ensured that the final system met both operational goals and technical constraints without compromise.

The project serves as a clear example of how engineering partnerships, grounded in shared understanding and practical problem-solving, can turn off-the-shelf components into high-impact, customized infrastructure.

Applications Beyond Horticulture: Where Centralized Power Makes Sense

While this deployment was tailored for a horticultural environment, the design principles and technical benefits of the SHP-10K-based centralized power architecture extend well beyond grow rooms. Any facility that relies on distributed, high-density LED lighting or DC-powered equipment can benefit from centralized power delivery with high efficiency, modularity, and simplified control.

Potential Application Areas

Supermarkets and Big-Box Retail: Centralized power racks can drive large banks of LED ceiling fixtures more efficiently than individual power adapters, especially when lighting layouts are updated for energy optimization.

Warehouses and Distribution Centers: Facilities with long lighting rows or automated storage systems can reduce wiring complexity and maintenance by moving power electronics out of the ceiling and into rack-mounted control areas.

Data Center Lighting and Support Systems: Support infrastructure in data centers, such as DC-powered LED lighting, airflow monitoring, and security access control, benefits from centralized power units that reduce ceiling clutter, enhance reliability, and allow for remote diagnostics.

Smart Buildings and R&D Facilities: Applications requiring programmable voltage/current control, remote ON/OFF switching, and simplified system diagnostics can benefit from the SHP-10K’s built-in analog control features.

Broader Applications for Centralized AC-DC Power

Beyond high-density lighting, centralized AC-DC systems like the MEAN WELL SHP-10K are well-suited for any environment demanding scalable, high-efficiency power delivery. These applications benefit from centralized control, reduced thermal footprint, and simplified infrastructure.

EV Charging Infrastructure: Centralized 10 kW modules can serve as building blocks in high-voltage charging cabinets, where DC output and parallel scalability align with the needs of modular, high-reliability EV chargers.

Industrial Automation and Robotics: Distributed actuators and motion systems require tightly regulated DC buses. Centralized power units reduce maintenance complexity, consolidate control wiring, and ensure predictable power quality across robotic cells.

Semiconductor and Test Equipment: Lab and fab applications often require programmable voltage/current sources with tight ripple and thermal characteristics. SHP-10K’s analog control and protection features make it a robust backbone for precision equipment.

Electrolysis and Process Control Systems: In electrochemical processes, stable DC under varying loads is critical. Centralized AC-DC conversion with 3-phase input and programmable output ensures high uptime and controlled process stability.

Conclusion

This project demonstrates how a thoughtfully designed, centralized power architecture, built with off-the-shelf components and customized through smart engineering, can deliver measurable results in highly-dense and demanding lighting environments.

By replacing a complex, heat-generating system with MEAN WELL’s high-efficiency SHP-10K power supplies, and integrating them into modular rack systems with analog control and simplified wiring, the horticultural customer gained:

Significant heat reduction in climate-sensitive spaces

Greater operational simplicity with analog dimming and ON/OFF control

Modular maintainability and localized fault containment

Scalability for future expansion using repeatable rack designs

Drastically improved energy performance with 96.5% efficient power delivery across 720 kW

From design to deployment, the collaboration between the customer, Sager Electronics, and MEAN WELL turned a real-world constraint into a repeatable infrastructure success.

Get in Touch

Looking to simplify your own high-density power delivery challenge?

Whether you're powering LED lighting, automation systems, or IT infrastructure, Sager Electronics can help engineer a solution that’s scalable, practical, and ready for the field.

Contact Sager Electronics to start the conversation.

References

[1] MEAN WELL Enterprises Co., Ltd. MEAN WELL SHP-10K Series Enclosed Power Supplies [Internet]. Available from: https://www.meanwell.co.uk/power-supplies/high-voltage/shp-10k-series

[2] Sager Electronics. SHP-10K-380 – MEAN WELL [Internet]. Sager Electronics. Available from: https://www.sager.com/product/shp-10k-380-mean-well/6384971