Beyond Rigidity: The Rise of Flexible Electronics

Exploring the transformative journey of flexible electronics and how additive manufacturing is the future.

The Evolution of Electronics

The history of electronics dates back to the late 19th century, with the discovery of electrons and the ability to control the electric current flow between them using vacuum tube devices. Of course, electronics today bear little resemblance to turn-of-the-century electronic systems, and this is due in large part to the emergence of printed circuit boards (PCBs). While the first technology to begin to resemble a PCB was patented in 1903 by German inventor Albert Hanson, the electronic devices, which connect wires in a circuit, would not be widespread until the 1960s, with the integration of printed circuit boards into consumer electronics like televisions and home radios. At the time, PCBs offered a number of benefits over existing circuit boards: they were lighter, smaller, and cheaper to produce.

Over the next decades, printed circuit boards would continue to evolve, with manufacturers finding ways to make the circuitry even more compact and cost efficient. For example, the ability to create multiple layers within a single PCB opened the door to smaller electronic systems with more capabilities.

Flexible electronics were also developing over this time, evolving significantly from their earliest iterations in the early 20th century (metal conductors mounted on wax-coated paper). In the 1960s, for example, flexible solar cells made from thin silicon were invented. Following this, the development of conductive polymers and other material advances paved the way for today’s flexible electronics.

Additive technologies, like 3D printing, are now at the cutting edge of both non-flexible and flexible electronics. This technology involves the deposition of conductive and insulating materials onto a substrate to create a circuit. Additive solutions like Voltera’s high-resolution printing platform are unlocking more opportunities for rigid and flexible electronics by expanding design possibilities and enabling a greater range of materials. In this article, we will be focusing specifically on additively manufactured flexible electronics, looking at how they are made, what benefits they offer, how they can be used, and more.

What are Flexible Electronics?

Flexible electronics are a type of electronic device characterized by their ability to flex, stretch and/or conform. Unlike rigid PCBs, this means they can bend without breaking, expand or stretch and return to their original shape, and adapt to whatever surface they are applied to. In the simplest terms, flexible electronics are achieved by mounting flexible conductive elements onto a flexible substrate, typically made of plastics like polyimide or polyethylene terephthalate (PET), or other flexible materials like paper or metal foil.

Materials and Components

Flexible electronics typically utilize a range of specialized materials to achieve their unique properties. The most common substrate material is polyimide, valued for its excellent thermal stability and flexibility. PET is another popular choice, due to its cost effectiveness and good mechanical properties. For the conductive elements, materials like silver, copper, and conductive polymers are widely used as they offer both excellent electrical conductivity and ductility.

Transparent conductors like indium tin oxide (ITO) or conductive polymers are used for applications requiring transparency, such as in flexible displays. These materials are carefully chosen to ensure that the final electronic device retains its flexibility, durability, and functionality, meeting the demands of various applications in fields like healthcare, consumer electronics, and wearable technology.

In the manufacture of flexible electronics, printing techniques such as inkjet printing, screen printing, and roll-to-roll printing (R2R) are often employed. Inkjet printing, for example, is a non-contact process that involves jetting tiny ink droplets using an array of nozzles onto a substrate. Some specialized inkjet printers, such as Voltera’s NOVA system based on its direct-ink-write technology, are designed to deposit a wide range of materials, such as conductive inks, with ultra-precise accuracy on various substrates.

Applications of Printed Flexible Electronics

While printed flexible electronics are still in their infancy, the potential applications for these devices is vast. Flexible electronics with small footprints are being investigated across many industries, from healthcare, to energy, to consumer goods, to make more efficient and innovative products. Let’s take a look at some application areas for printed flexible electronics.

Wearable Technology

Flexible electronics have numerous applications in the field of wearable tech, and have a big impact on how devices fit on our bodies and integrate with our daily lives. For example, fitness trackers made from flexible electronics can be integrated into wearable bands or even clothing that users can wear during exercise or daily activities. The flexibility of these devices ensures they remain unobtrusive, conforming to the body's movements while accurately tracking physical activity and vital signs. For wearable applications, electronics are printed onto a flexible material, which can then be applied directly to the surface of the wearable. In one study, Voltera’s technology was used to print a wearable heater, which was successfully applied to a pair of denim jeans resulting in a functional heating patch.

Medical Devices

The medical field is also increasingly interested in leveraging flexible electronics for the development of advanced medical devices. Wearable health monitors utilize flexible electronic circuits to conform to the contours of the human body, providing continuous, real-time health monitoring without causing discomfort or hindering the wearer's movement. Such wearable monitors can track a variety of health metrics, including heart rate, blood pressure, oxygen saturation, and even electrocardiogram (ECG) readings. The flexibility of these electronics is crucial, as it allows the sensors to maintain close contact with the skin, ensuring accurate and consistent data collection. For example, a researcher at York University recently investigated the use of printed flexible electronics for biomedical tattoos, which conform to the patient’s skin for greater comfort. These could be used to capture ECG readings, to integrate with prosthetics, and more.

Consumer Electronics

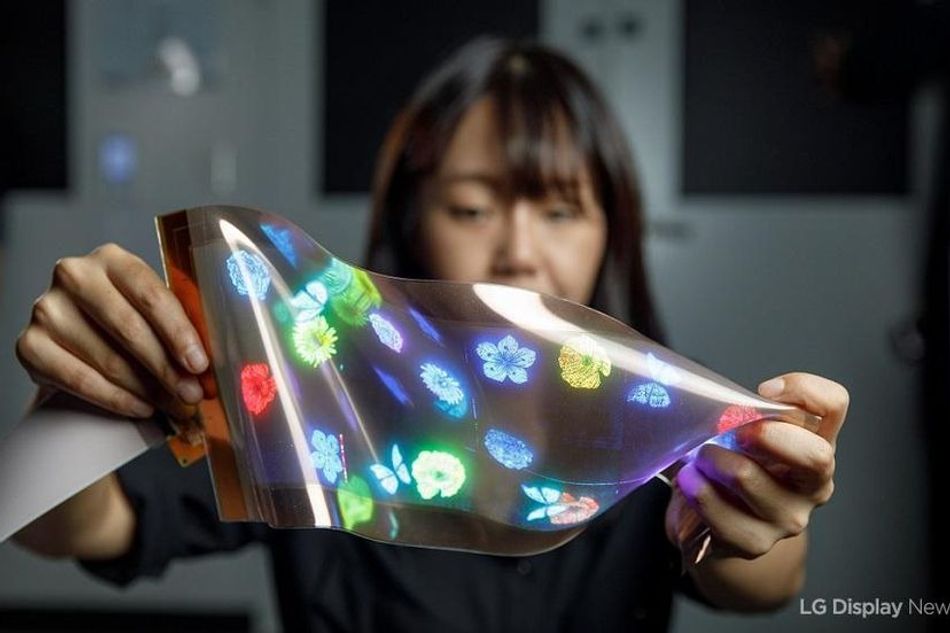

While still a nascent application area, there is huge potential for flexible electronics in consumer electronics. A striking example is the development of flexible displays used in smartphones, laptops, and televisions. These displays utilize flexible electronic components to create devices that are lighter and thinner than their traditional counterparts and offer new form factors such as foldable or rollable screens. These flexible screens could also be used in cars or in wearables, eliminating previous design restrictions on media and consumer electronics by being more adaptable.

Image: LG Display

Robotics and Automation

Robotics can also benefit from flexible electronics, as the technology opens up the door for pliant and deformable soft robots that can be integrated directly with sensors or electronics components. These soft robots can interact safely and efficiently with humans and complex environments, and can handle even the most fragile components in production or assembly lines. And that’s just the tip of the iceberg: robots with stretchable bodies could also have exciting applications in healthcare, search and rescue, and more.

Energy

Flexible, stretchable, and conformable electronics also have the potential to transform certain applications in energy. For example, the ability to directly print flexible electronics can enable the seamless integration of solar panels onto various surfaces, from architectural designs to portable applications, and offer improved durability and aesthetic adaptability. There is also growing interest in the development of flexible energy storage devices (FESDs), which could be used to power wearable tech and other flexible electronic products without the need for a bulky power source or wiring.

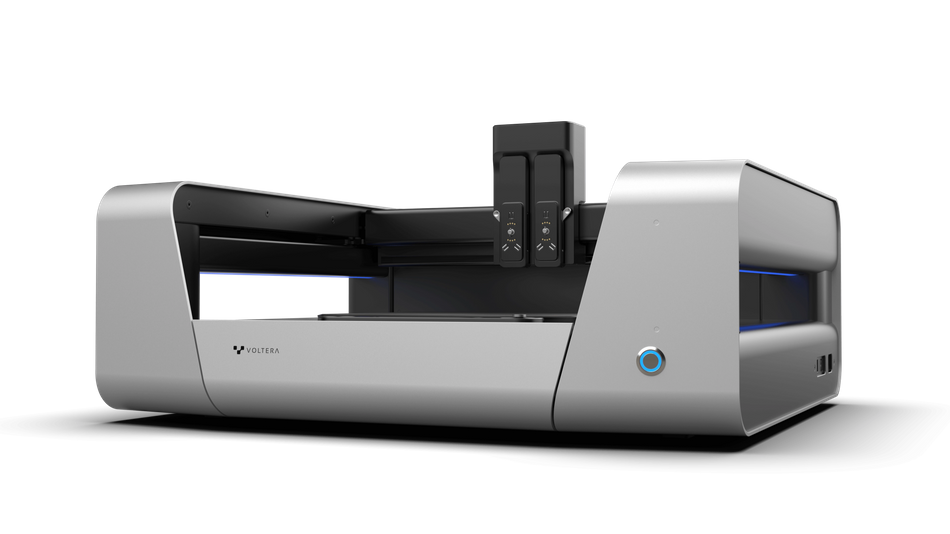

Voltera's NOVA

In the rapidly evolving field of printed electronics, Canadian company Voltera is doing something highly unique. It develops and supplies dispensing systems for the rapid prototyping of printed electronics, from traditional circuit boards to flexible, stretchable, conformable, and biocompatible electronics. Their approach enables users to quickly iterate and test designs, enabling faster design development and a more accessible method for industry experimentation and innovation. Notably, their systems don’t require expert knowledge and they can be used with a broad range of inks and materials enabling unfettered design freedom.

NOVA Printer

Voltera’s NOVA printer enables high-resolution printing using a range of functional materials and screen-printable inks. The system works with a wide range of conductive and insulating inks, including copper, silver and carbon-based inks ranging from 1,000 to 1,000,000 cps. NOVA deposits these conductive and insulating inks onto various substrates, including flexible, rigid and heat-resistant materials, with incredible precision (capable of printing a line width of 100 µm and a resolution of up to 17 µm/pixel). In terms of flexible substrates, it is possible to print on materials like paper, polyimide films, PET, and more.

Used by researchers and product developers to streamline their R&D processes, NOVA enables on-the-fly design changes and immediate feedback on new ideas, significantly accelerating timelines and reducing costs. To date, NOVA has successfully been used to manufacture various printed electronic components, such as RFID tags, ceramic PCBs, strain gauges, electrodes on glass, FSR sensors, and FHE circuits.

Direct-Ink-Write Dispensing

At the core of the NOVA system is Voltera’s direct-ink-write dispensing technology, which eliminates the need for tooling, waste, and extensive cleanup. This approach results in a 90% faster iteration time and a 96% reduction in material costs, highlighting its efficiency and cost-effectiveness.

High-Resolution and Closed-Loop Dispensing

NOVA offers high-resolution, closed-loop dispensing, which ensures increased material options due to compatibility with a wide range of viscosities. This feature also reduces risk by allowing for the validation of designs and materials in the lab before transitioning to production. The printer achieves consistent results with integrated closed-loop pressure feedback and temperature-controlled dispensing, offering a line width as fine as 100 µm, depending on material properties and nozzle geometry.

Adaptability

The printer's large, configurable print area of 220 x 300 mm makes it adaptable to various applications. It can handle both rigid and compliant substrates, with a porous titanium vacuum table ensuring uniform suction for flexible and soft substrates. The mounting grid features allow for the development of application-specific fixturing, further enhancing the printer's adaptability.

With its advanced features and capabilities, NOVA is poised to be a game-changer in the field of printed electronics, offering unparalleled flexibility, efficiency, and innovation in materials and design.

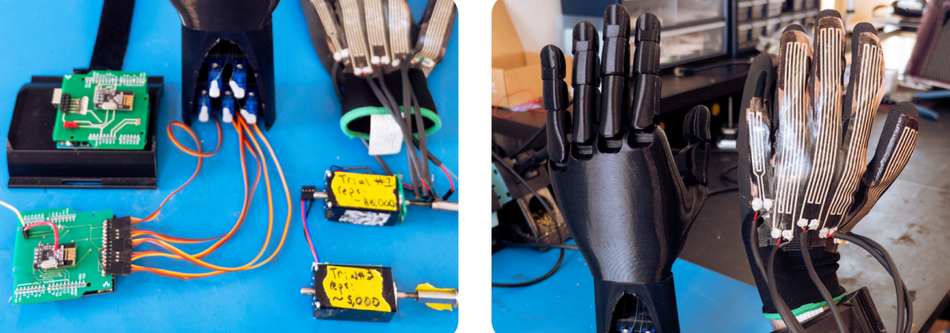

Case Study: Robotic Hand and Control Glove

To demonstrate NOVA's capabilities for flexible electronics, the Voltera team built a robotic hand and a control glove integrated with printed stretchable strain sensors and LED lights. The strain sensors are designed to light up when the glove’s wearer opens or closes their hand, and the brightness of the lights varies depending on the amount of strain on the sensors as the fingers move (i.e. the lights dim when exposed to increased resistance). These strain sensors were cleverly adapted to function as a control mechanism, using the degree of resistance experienced by the glove’s sensor to control the movements of a Bluetooth-connected robotic hand.

The glove sensors were made by printing traces of DuPont PE874 stretchable ink on a DuPont TE 11-C TPU substrate, which were then heat-laminated onto the glove using a T-shirt press. Then, wires were attached to the glove traces using MG Chemicals 9400 conductive adhesive. Lastly, the robotic hand was 3D printed and integrated with five servo motors to move the fingers. An Arduino, connected via Bluetooth to the glove, controls the robotic hand’s movements based on the glove’s movements. The whole project took only two months to complete.

Interestingly, strain gauges can be made by printing flexible conductive ink onto almost any stretchable material. The sensor-integrated glove demonstrates how this technology can be applied to a real-world robotics use case. It is also a fine example of how accessible the NOVA system is and how it can be used to develop new ideas and products on a rapid timeline.

Check out the full case study here. In addition, you can also find more case studies on Voltera’s website.

|

Voltera’s Case Study Robotic Hand and Control Glove. Image credit: Voltera. |

Future Potential

The adaptability, robustness, and versatility of flexible, stretchable, and conformable electronics will positively impact multiple industries, particularly healthcare and wearables.

Innovative manufacturing approaches, such as Voltera’s NOVA, enable the industry to advance at a pace unprecedented in electronics.

References

Zhao, Y., Kim, A., Wan, G. et al., 2019. “Design and applications of stretchable and self-healable conductors for soft electronics”

Global Electronic Services. “The Future of Flexible Electronics”

Voltera. “Case Study: Robotic Hand and Control Glove with Printed Stretchable Strain Sensors”

Cassiano Ferro Moraes, 2023. “Flexible and Printed Electronics: Breakthroughs, Applications, and Challenges”

Guang Z., Wei Q., Tiejun Z. et al., 2014. “Self-Powered, Ultrasensitive, Flexible Tactile Sensors Based on Contact Electrification”

Karsten S., Nils N. and Martin S., 2019. “Flexible, stretchable, conformal electronics, and smart textiles: environmental life cycle considerations for emerging applications”

Qing-Hua Lu, Feng Zheng, 2018. “Polyimides for Electronic Applications”

Corzo D, Tostado-Blázquez G, Baran D. Flexible electronics: status, challenges and opportunities. Frontiers in Electronics. 2020 Sep 30;1:594003.