Advanced Connector Systems for Industrial Robotics

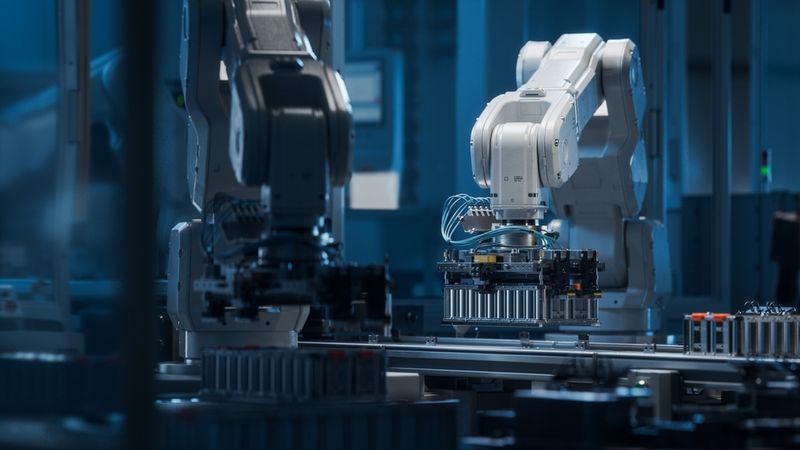

In the rapidly growing field of industrial robotics, reliable connectivity is essential for maintaining high signal integrity, especially in environments characterized by continuous motion and harsh conditions.

Introduction

The industrial robotics landscape is experiencing remarkable growth and transforming manufacturing operations worldwide. The market is expected to expand dramatically, with projections growing from $17.78 billion USD in 2024 to $84.36 billion USD by 2034. This expansion is driven by labor shortages, accelerating automation demands, and the paradigm of Industry 5.0. Complementing this growth, the collaborative robot market is rapidly expanding at 31.6% CAGR, and expected to reach $11.64 billion USD by 2030.

While companies navigate this market growth, connectivity has emerged as the backbone of industrial robotics. Modern automation systems demand far more than conventional electrical connections. They require advanced connector solutions that can endure continuous motion, resist harsh environments, and maintain the high signal integrity demanded by modern robotic applications. These trends underline the important role of advanced connector systems as enablers of reliable automation. Without them, the next generation of robotics can’t be fully realized.

The Connectivity Challenge in Industrial Robotics

Industrial robotics have unique connectivity challenges that differ from traditional automation applications. The continuous motion inherent in robotic systems means that cables and connectors are subject to constant forces that would quickly break down conventional solutions. Six-axis industrial robots are the standard in modern manufacturing, and pose a particularly complex challenge for cable management because traditional connections can’t accommodate the full range of motion required.

Environmental protection is another important challenge. Industrial robots operate in harsh conditions where exposure to chemical, dust, and temperature extremes is expected. In industrial environments, multiple robotic applications require a minimum protection of IP65 to protect against water ingress, dust intrusion, and chemical exposure that could compromise system integrity.

Signal integrity and power delivery are another layer of complexity. Modern industrial robots require simultaneous transmission of power, digital control signals, analog feedback, and increasingly high-speed communication protocols. Connector systems must simultaneously maintain signal quality, withstand the stress of continuous motion, and meet the space constraints of compact robotic designs.

Connectivity failures can come at a huge expense to production. According to industry research, cable issues are the number one cause of downtime in robotic work cells. Connectivity failure can cause cascading effects through an integrated production line, potentially costing thousands of dollars per hour in lost productivity, meaning that reliable connectivity is a business imperative.

The complexity of cable management in multi-axis robots has led to the adoption of segmented approaches, where cable routing is divided into sections corresponding to robot joints. However, this approach requires connector solutions that can handle frequent mating and demating while maintaining environmental and signal requirements. Traditional connector systems with bulky size and shape and complex multi-step mating often become maintenance bottlenecks.

Ultimately, the ability of a connector system to balance durability, compactness, and signal integrity determines whether a robot operates as a productive asset or becomes a costly maintenance liability. These demands explain why connectivity has become one of the most decisive factors in modern robot design.

TE Connectivity's HDC H3A-TIC-LOQ Solution

TE Connectivity has addressed these challenges in connectivity with their innovative HDC H3A-TIC-LOQ connector system, which is specifically engineered to meet the demands of modern robotic applications. This system is a significant advancement in connector technology, as it combines compact design with user-friendly features and directly addresses the biggest challenges in industrial environments.

The HDC H3A-TIC-LOQ system has a high-density design with 32 contacts in a compact form factor. The contact density saves a significant amount of space in applications where every cubic centimeter is critical. This is particularly important in collaborative robotic environments, where compact designs are required for closer human-robot interaction. The system has a modular architecture and is compatible with standard HDC HQ inserts, making it flexible for system integration while maintaining the benefits of advanced TIC-LOQ housing technology.

The housing itself incorporates the innovative TIC-LOQ (Twist, Insert, Connect - Lock On Quickly) automatic locking system. Unlike traditional heavy-duty connectors that require more complex two-step mating procedures, involving careful alignment and separate locking actions, the HDC H3A-TIC-LOQ system allows technicians to complete the connection in just two seconds through a single, intuitive motion. This reduction in mating time and complexity has been shown to directly reduce maintenance and downtime, resulting in improved production activity for robotic installations.

TE Connectivity’s system also achieves environmental protection, with an IP65 rating when mated. This provides robust protection against dust ingress and water jets common during industrial cleaning operations. The connector system has an operating temperature range of -40°C to 125°C, making it reliable across extreme temperature variations in industrial environments, from cold storage facilities to high-temperature manufacturing.

Electrical specifications of the HDC H3A-TIC-LOQ system are also tailored for industrial robot applications. The system maintains its compact form factor while providing a current rating of 2.2A per contact and voltage rating of 32V to effectively handle the power and signal requirements of modern robots. Its 0.8kV impulse voltage rating provides additional protection against electrical transients common in industrial environments with heavy machinery and variable frequency drives.

Connector materials also reflect the demanding mechanical requirements of industrial robots. The die-cast zinc alloy housing provides durability and EMC shielding, while the polymer insert keeps the electrical insulation and contact retention reliable. This combination of materials maintains connector stability that is essential for reliable electrical performance.

The system’s compatibility with standard HDC HQ connectors is also a big advantage for system integrators and end users. Existing cable assemblies and termination procedures can often be retained when integrating the HDC H3A-TIC-LOQ system. By reducing mating complexity, maximizing space efficiency, and ensuring environmental resilience, the H3A-TIC-LOQ bridges the gap between laboratory design and factory-floor reliability. For engineers, it is a system that simplifies integration and sustains long-term performance.

Real-World Applications and Benefits

The versatility of advanced connector systems like HDC H3A-TIC-LOQ is demonstrated through diverse applications across multiple industries. For example, in automotive manufacturing, these connectors have allowed engineers to develop sophisticated robotic assembly lines. Modern automotive robots equipped with advanced connectivity solutions can perform precision welding, painting, and assembly with repeatability around ±0.01 mm. Compact, reliable connectors facilitate the integration of multiple robotic systems in coordinated cells and support flexible manufacturing that can produce multiple models on the same line.

In electronics assembly, miniaturization challenges exceed human capabilities, requiring robots that accurately place components as small as 0.1mm. Advanced connectors enable high-speed data communication for real-time machine sensing and support continuous operation in cleanroom environments. This level of precision reduces defect rates from over 3% using manual processes to under 1% with robotic assembly.

Collaborative robots (cobots) also benefit from compact connector designs that maintain workflow and safety. The HDC H3A-TIC-LOQ’s compact form and easy mating suit cobot applications that require frequent reconfiguration and maintenance access. Cobots can boost productivity while reducing injuries by automating repetitive and physically demanding tasks.

Predictive maintenance enabled by advanced connectors cuts downtime by 25-30%. IoT sensors monitor connector integrity and cable condition. In doing so, they provide early warnings and enable planned repairs, preventing costly emergency shutdowns and maintenance.

Additionally, Industry 5.0 integration focuses on human-robot collaboration and mass customization. Advanced connector systems support rapid reconfiguration in flexible manufacturing, enabling robotic cells to produce different products. Early adopters report significantly reduced cycle time due to reduced maintenance, improved reliability, and faster changeover.

These use cases illustrate how robust connectors move beyond a supporting role and become central to robotic innovation. From precision assembly to predictive maintenance, the choice of connector can directly shape throughput, safety, and the economics of production.

Future Trends and Technological Evolution

AI-driven automation is also placing new demands on connectivity. Robots must adapt to material, process, and product variations in real-time, requiring high-bandwidth links for transmitting large sensor data and complex commands with low latency. Future connectors must support current and emerging protocols, and provide bandwidth for increasing complex AI algorithms.

Mobile manipulators, which combine autonomous mobility and precise robotic arms, also require robust connectors that can accommodate vibration, acceleration, and environmental changes due to movement. Unlike fixed robots, mobile manipulators have unique connectivity challenges that demand innovative and flexible solutions.

5G and edge computing are reshaping robotic architectures. These technologies offload complex computations to edge servers while maintaining low latency for precise control. Connectors must support high-speed data transmission with industrial reliability. Additionally, 5G allows engineers to develop new applications like remote robot operation and collaborative AI systems across industrial installations.

Components are increasingly miniaturized as sensors and AI increase connectivity density demands in smaller packages. Advanced manufacturing means that engineers can design contact pitches below 1mm without sacrificing robustness. This is essential for space-constrained applications.

Sustainability is an important factor in connector design and materials. Manufacturers aim to reduce their environmental impact by using recycled materials, implementing energy-efficient manufacturing processes, and extending product life. New materials, like bio-based plastics and nano-structured contacts, are the future of performance balanced with sustainability.

Predictive maintenance is another factor toward improved sustainability. When combined with embedded IoT sensors, predictive maintenance detects wear, changes in electrical resistance, and environmental intrusion early. Advanced connectors enable real-time feedback for reduced downtime and continuous improvement.

As robotics evolve alongside AI, 5G, and sustainability initiatives, connector systems will continue to define the limits of what machines can achieve. The next generation of automation will rely on these components to deliver both performance and adaptability in equal measure.

Conclusion: Enabling the Next Generation of Industrial Robotics

Advanced connector systems have become key enablers of robotic innovation amid a booming industrial robotics market projected to reach $60 billion by 2034. TE Connectivity’s HDC H3A-TIC-LOQ solution addresses modern connectivity challenges with high-density design, quick mating, environmental protection, and modular flexibility. As Industry 5.0, AI, mobile manipulation, and 5G converge, engineers must prioritize advanced connectivity to meet evolving demands. For engineers embarking on robotic automation projects, choosing robust connector solutions like the HDC H3A-TIC-LOQ is critical to minimizing downtime and maximizing performance. In this way, advanced connectors are not just hardware. Rather, they are strategic enablers of industrial resilience and progress.