Adequate corrosion assessment on gas distribution pipelines

Early 2021, IPEC invested in a Go!SCAN Spark 3D scanner with Pipecheck, a powerful pipeline integrity management software to accurately measure corrosion.

All kind of pipelines have to be checked on a regular basis for corrosion and mechanical damages. These tasks are often performed by service providers such as the Irish company IPEC Inspection Ltd. which was founded in 1973. They cater for numerous different industries in all shapes and sizes, specializing in Non-Destructive Testing (NDT), Advanced NDT, Welding Inspection & Certification, Vessel Inspection, Pipeline Inspection, Management & Supervision, Quality Assurance, Corrosion Assessment & Analysis, 3rd Party Vendor Assessment, Asset Owner Consultation & Quality Assurance.

Corrosion Assessment

Recently, IPEC was commissioned with the project to carry out an adequate corrosion assessment on a 610mm OD x 14.2mm WT, API 5L X52 gas distribution pipeline in Cork, Ireland. A P11 assessment using a pit gauge & UT set was the old-fashioned way of carrying out this inspection and this was the way it was carried out for many years in Ireland. IPEC clients felt a new approach was required, a method which would save time, while also improving the quality of test results. This is where the Creaform Scanner stepped in.

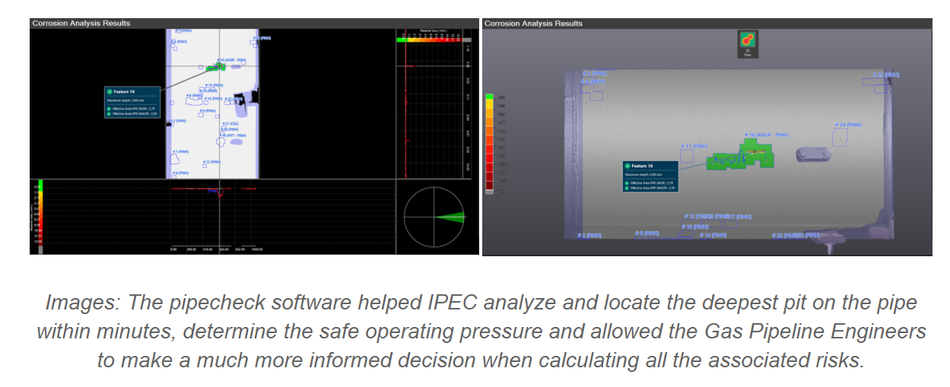

Early 2021, IPEC invested in a Go!SCAN Spark 3D scanner with Pipecheck, a powerful pipeline integrity management software to accurately measure corrosion. The Go!SCAN 3D offers the fastest and easiest 3D experience for NDT technicians who perform pipeline inspections for different types of damage, particularly corrosion. Its main benefits for NDT are : quick field deployment and capability to provide complete 3D picture by capturing the texture of the pipe. A lot of time, part of NDT procedure includes writing notes on the pipe and taking pictures. The Go!SCAN can capture theses notes and report them into Pipecheck. The time spent for inspections is thus shortened, making it an ideal solution for service companies and also IPEC is happy with its new tool.

James Murphy, Operations Manager at IPEC, explains: “It would have been possible to realize this project with our old technologies, but the quality of results from using the Creaform system is of a much higher standard. A manual P11 assessment would not of produced the same quality of report & the additional labor costs would have been a lot higher. With the new solution we save approximately 2 days of work and more specifically reporting time. The implementation of this Pipeline Integrity Assessment solution drastically improved our knowledge base and definitely opened our eyes to the current technologies currently available to us. We are trying to push this technology on our clients & hope to prove to them how successful it can be.”