3 Ways to help you find the right CNC machining materials

Almost any plastic or metal can be manufactured by CNC machining. It means that you have more options when selecting the right materials for your CNC machined parts, and it is quite a challenging work to find the exact material that meets all requirements for your product development.

Photo by Mastars on Unsplash

Almost any plastic or metal can be manufactured by CNC machining. It means that you have more options when selecting the right materials for your CNC machined parts, and it is quite a challenging work to find the exact material that meets all requirements for your product development. Here are 3 general rules you should keep in mind when you select the materials among the numerous options, and the rules may help you get the best option.

Know the requirements for materials of your parts:

You know much better the parts application when you develop the products, so taking all possible factors in- cluding parts final application, mechanical property, cost and the surface treatment into consideration will be necessary.

Final Application

The final application of your parts can have the most significant effect on your selection of food grade, medical grade or other special high-performance engineering materials. Environment temperature and contact medium should be considered as well.

Mechanical Property

Mechanical properties include strength and ultimate strain in several modes, impact strength, abrasion resistance, ductility, coefficient of friction, hardness, and machinability.

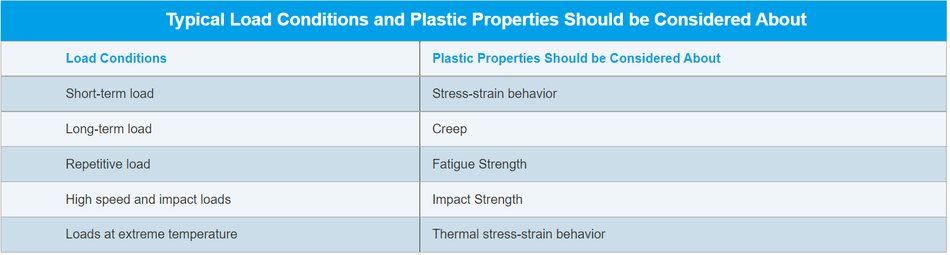

Take plastic materials for instance, when selecting the plastic materials, the engineer should analyze conditions of parts load, including load ability, types and time, then compare the physical properties of plastic materials. See the below sheet five typical load conditions and plastic properties engineers should consider about.

Electrical and Thermal Requirements

If you are considering the plastic materials, you should evaluate on the operating temperature of plastics, and the electrical property is crucial in the parts of household appliances.

Identify the common materials for your parts:

our engineers select several common materials that frequently used by our customers. The below is the properties of common material:

Considering all aspects when selecting the right material:

Over more than a decade, the engineers of RPWORLD has accumulated experience on how to find the right material, and considering all aspects mentioned above. If you have more questions about CNC machining selection, please contact us for more information, the professional engineers will make the best choice for you.