World-First Adoption of Thin Film Lithium Niobate (TFLN) as Imaging Device

As augmented smart glasses technology edges closer to mainstream adoption, engineers face challenges around display performance. Namely, many seek to achieve higher resolution without driving up power consumption and device bulk.

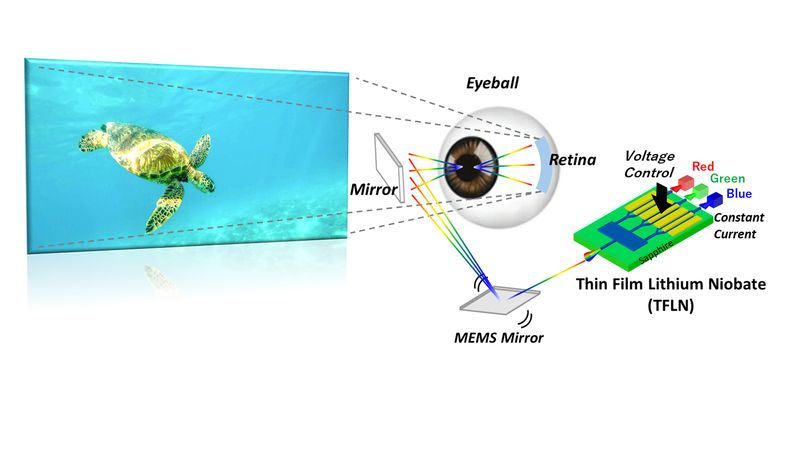

Among emerging solutions, Direct Retinal Projection (DRP) stands out. Rather than projecting onto a screen, DRP beams images directly onto the retina to unlock ultra-clear visuals with minimal eye strain. Yet the effectiveness of DRP hinges on the performance of the underlying light modulation device. That’s why TDK is now repurposing thin film lithium niobate (TFLN), a material long prized in telecommunications, for next-generation AR smart glasses displays.

For decades, lithium niobate has been trusted for high-speed modulation in long-haul infrared optical communication. TDK's breakthrough lies in applying this well-established material to the visible light spectrum and adapting it for DRP imaging. With this world-first innovation, TDK is delivering on promises of higher resolution and significantly lower power consumption.

The TFLN Device Concept

In traditional laser projection systems, color modulation is achieved by dynamically adjusting the injection current to red, green, and blue (RGB) laser diodes. This current-based approach alters the power level of each laser, creating the desired mix of colors. However, this method introduces two fundamental constraints: significant power consumption due to current control to change colors thermal inefficiencies and a practical upper limit in switching speed (i.e., typically around 1 GHz) due to the carrier dynamics in semiconductor laser junctions.

TDK’s lithium niobate-based projection module fundamentally rewrites this equation. Instead of modulating color through current, the system fixes the injection current at a low, stable level and applies a voltage across a TFLN electro-optic modulator to dynamically alter the phase of each RGB laser beam. This separation of power delivery (via fixed current) and modulation (via voltage) brings profound improvements in both efficiency and speed.

At the center of the system is an Active Photonic Integrated Circuit (Active-PIC) fabricated from sputtered TFLN. These modulators leverage the Pockels effect, which is an intrinsic property of lithium niobate wherein the refractive index changes linearly with an applied electric field. By exploiting this effect, TDK can induce precise phase shifts in the optical waveguides without generating excess heat or requiring large drive currents. The result is color modulation at frequencies up to 10 GHz and more, a number ten times faster than what’s possible with laser diode current modulation.

In simple terms, TFLN enables color tuning without altering the energy driving the laser itself. This stability makes it ideal for the DRP method, as laser beams must scan across the retina at high speeds to build up an image. Faster switching means higher effective resolution and smoother rendering, while lower power draw extends battery life in AR smart glasses.

TDK’s Breakthrough in Sputtered TFLN

One of the primary challenges that historically prevented lithium niobate from entering the consumer electronics space was its fabrication method.

Traditionally, TFLN devices have been manufactured by bonding thick, bulk-grown crystals onto silicon or other substrates. While this method works well for high-performance optical communication systems, it presents serious drawbacks for mass-market applications. Bulk bonding is inherently low-yield, expensive, and difficult to scale. It also limits device miniaturization due to the thickness and fragility of the bonded crystals.

TDK’s breakthrough comes in the form of a proprietary sputtering process that enables the deposition of high-quality, single-crystal-like TFLN directly onto sapphire substrate. Using a precisely tuned sputter deposition technique, TDK forms several hundred nanometer-thick TFLN layers with uniform thickness and crystallinity across large-diameter wafers. This process is compatible with standard semiconductor fabrication workflows and allows wafer-scale integration alongside etching, lithography, and metallization steps.

Bonded films require manual alignment and polishing. In contracts, sputtered TFLN can be patterned and processed to drastically reduce cost and manufacturing complexity. Furthermore, TDK’s sputtered films exhibit excellent electro-optic performance, with X-ray diffraction confirming the good crystallinity required for low-loss optical waveguides. This has allowed TDK to fabricate fully functional phase modulators and multiplexers in TFLN for the visible light spectrum: a world-first.

A World-First in Visible Light Modulation

While lithium niobate has long been used in infrared applications, TDK is the first to demonstrate its viability for full-color visible light modulation. This includes independent modulation of red, green, and blue lasers and real-time color mixing through an integrated multiplexer.

In lab demonstrations, TDK has successfully shown RGB phase modulation and full-color output using their sputtered-film Active-PIC. Notably, TDK has also proved that the system works within the constraints of wearable AR smart glasses validating the design with direct retinal projection demos.

Three Advantages of TDK’s TFLN

Modulation Speed

In traditional laser-based systems, modulation speed is limited by the physical properties of the laser diode itself. Specifically, the carrier recombination rate within the semiconductor junction caps switching frequencies around 1 GHz. While sufficient for lower-resolution displays, this frequency limit restricts how quickly the laser beam can toggle between red, green, and blue during raster scanning. For DRP applications where individual laser pulses trace an image line by line across the retina, this modulation rate becomes a bottleneck to achieving higher resolution.

TDK’s TFLN modulators bypass this limitation by decoupling color control from laser current. Instead, they leverage the Pockels effect to enable optical phase modulation purely through applied voltage at frequencies up to 10 GHz and more. This tenfold increase directly translates into faster pixel transitions and a resultant higher number of color changes per scan line and per frame. Practically, this means TFLN modulators can support 4K and 8K retinal imaging while maintaining frame rates up to 60 fps without flicker. It also opens the door to future high-frame-rate, high-pixel-density displays such as those required for light-field rendering and retinal microdisplays.

Scalability

The scalability of TDK’s TFLN architecture stems from its use of Active-PIC design. Whereas discrete optical systems require manual assembly of modulators, multiplexers, and beam combiners, the Active-PIC consolidates all light-processing elements onto a single TFLN chip. Each waveguide, multiplexer, and modulator is lithographically defined with submicron precision, enabling complex optical functionality in a compact footprint.

Such an approach allows resolution to scale through architectural duplication, not through physical expansion. For example, increasing from 720p to 4K+ is as simple as expanding the number of modulator paths and multiplexing channels on the chip, without enlarging the overall module or increasing system power. The uniformity and reproducibility of the sputtered TFLN process ensure consistent performance across high-density arrays for future displays to be scalble. Because all modulation is done on-chip, TDK’s system also reduces optical alignment complexity and allows for cohesive integration with advanced MEMS mirrors and other beam-steering technologies.

Efficiency

Efficiency in optical systems is largely governed by how light is generated and modulated. Conventional current-driven laser modulation requires constant active power to vary intensity, often resulting in unnecessary thermal load and significant energy loss due to resistive and thermal inefficiencies in the diode junctions. In AR glasses, this translates to shorter battery life, increased heat near the user’s face, and thicker device form factors to accommodate thermal management.

TDK’s use of TFLN reverses this paradigm. With the injection current fixed near the diode’s threshold and modulation achieved through external voltage, the optical output remains highly stable while power consumption is minimized. Voltage modulation in TFLN requires much less energy per switch and introduces negligible thermal dissipation, even at GHz speeds. In practical terms, this architecture consumes up to 75% less power than traditional current-modulated systems.

This has cascading benefits: battery size can be reduced, wearables stay cooler to the touch, and thermal drift, which can degrade image fidelity, is minimized. Furthermore, low-power operation unlocks more sustainable AR systems that are viable for extended wear.

TFLN Imaging Beyond AR Smart Glasses

Although AR smart glasses is the initial target, the implications of TDK's TFLN extend well beyond. Its high-speed modulation and low-power characteristics make it well-suited for

Data Center Optical Interconnects: Lower power and faster IO for photonic computing. Specifically, this is more important for a generative AI data center.

Quantum Photonics: TFLN's precise phase control and electro-optic properties are suitable for quantum circuits.

TDK's work with visible light also unlocks new possibilities for consumer-level Visible Light Communication (VLC) and ultrafast wireless transfer, which have long been limited by cost and complexity.

Scaling and Industry Adoption

As with any material breakthrough, industry adoption depends on cost, scalability, and ecosystem readiness. TDK’s sputtered TFLN approach addresses all three.

Combining TFLN modulators with photodetectors, amplifiers, and logic layers could enable fully self-contained one-chip ultracompact optical transceiver to be suitable for optical interconnect for generative AI.

Conclusion

TDK's use of TFLN for visible light modulation is a major moment in the evolution of AR smart glasses display systems. By replacing traditional current-based laser control with high-speed, voltage-driven phase modulation, TDK has enabled higher resolution, lower power consumption, and unprecedented scalability.

To learn more, get in touch with TDK here.