Tradition meets innovation: wire mesh solutions for industry

Resource scarcity and climate change are major challenges for today's (and tomorrow's) industries: More efficient processes and reduced emissions are needed to keep pace in a globalised world. Cutting-edge technologies like AI and renewable energies are making a valuable contribution.

The transition to more environmentally friendly processes and materials promotes sustainability and can lead to significant cost reductions in various industries. Finally, the ability to innovate is a key competitive factor in opening up new markets. These challenges can often not be met alone, but only hand in hand with a strong partner who understands the requirements. And offers the right solutions.

Customised metal mesh solutions for every industry

Located in the heart of Oelde, Germany, Haver & Boecker oHG has stood for outstanding expertise in wire mesh and packaging technology for generations. Both the Wire Weaving and Machinery Division are under the umbrella of this traditional family business, which is characterized by its innovative spirit, engineering know-how and tireless search for tailor-made customer solutions.

Haver & Boecker's Wire Weaving Division has established itself as a leading global manufacturer – a testament to the company's expertise and commitment. The brand stands for an impressive variety of product solutions that go far beyond the limits of conventional wire cloth applications. From filters and moulded parts for the various industries to filtration media for the chemical and pharmaceutical industries, to innovative architectural mesh – the applications are as diverse as the needs of the customers.

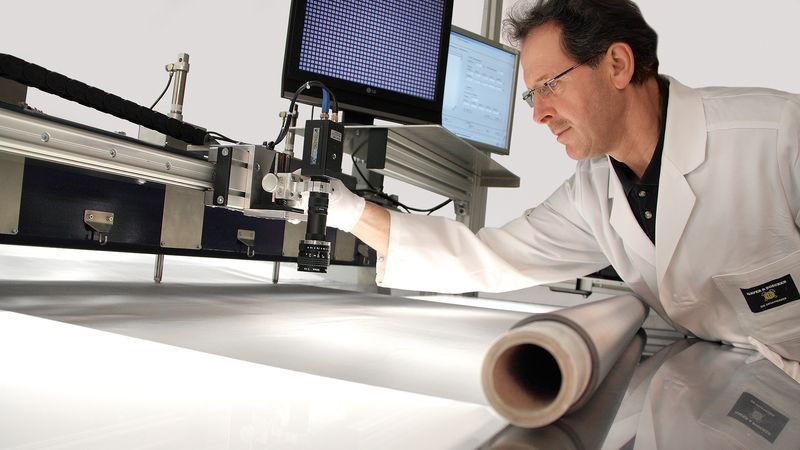

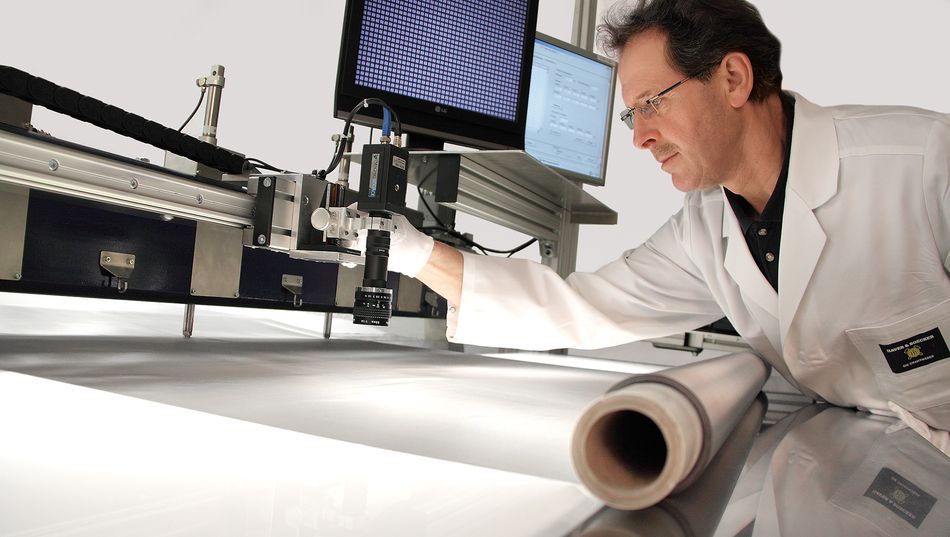

Haver & Boecker uses specially designed fine weaving machines and looms to produce products that often exceed specific requirements in terms of functionality and form.

Vertical integration and processes: A look behind the scenes

Haver & Boecker's exceptional vertical integration enables it to meet customer requirements precisely and efficiently – from the construction of the looms to the processing of the finest wires. Wire mesh of exceptional quality is produced on a production area of more than 30,000 m² in Oelde and other locations in Belgium and Canada. The ability to respond to almost any customer request underlines the flexibility and future security of the company.

Wide range of materials

The ability to work with all woven materials, from stainless steel to highly specialised materials such as titanium and hastelloy, enables Haver & Boecker to meet the most demanding customer requirements. Combined with the company's technical expertise, solutions can be developed that are perfectly tailored to the process.

Shaping the future with wire mesh

"The world of tomorrow needs our wire mesh" – this is the conviction and commitment of Haver & Boecker, a manufacturer that contributes to overcoming global challenges with pioneering solutions and products. Take electromobility, for example: flat and round wire mesh is already being used successfully to shield components in modern vehicles, including sensors and infotainment systems, from alternating fields that impair functionality. In addition to its excellent shielding attenuation, the material's flexibility and light weight are advantages.

The combination of decades of experience, technological innovation and customer proximity makes Haver & Boecker a unique partner for modern industry, whose products and solutions are indispensable today and in the future. Please browse the website for more information on applications and custom solutions. Haver & Boecker contacts are also available for a personal, no-obligation discussion.

Find out more about the Wire Weaving Division here.