Robots assemble reinforcing steel

The technology of ETH Zurich spin-off MESH allows for new shapes and was used for the Tor Alva in Mulegns, among others. And it makes construction more efficient, for example in prefabrication for the second Gotthard road tunnel.

The spin-off MESH is based in an industrial hall in Birr. (Image: Girts Apskalns)

This article was first published on

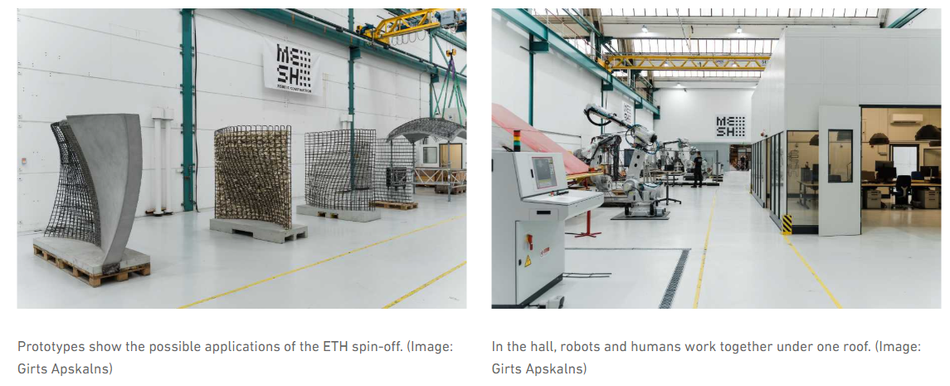

ethz.chAmmar Mirjan walks through a sprawling industrial hall in Birr in the canton of Aargau, where Brown, Boveri & Cie. once manufactured turbines. The huge cranes under the striking shed roof are not part of the typical atmosphere of a start-up. But the ETH spin-off MESH, which Mirjan founded together with Mattis Koh three years ago, needs space for technology development. The company, which has around 10 employees, has rented 800 square meters in the halls to automate work with reinforcing bars in the construction industry using robots.

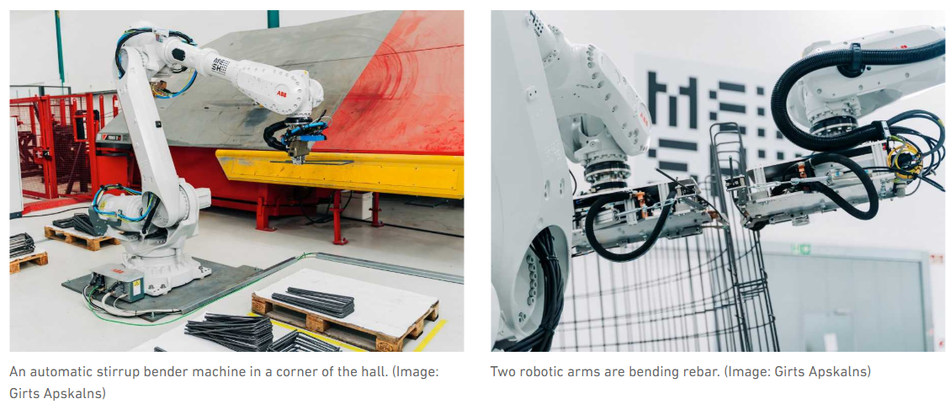

Mirjan once completed an apprenticeship as an automation engineer at ABB before studying architecture and completing a doctorate at ETH Zurich with Gramazio Kohler Research. MESH's technology is the result of several research projects, including that of the National Center of Competence in Research Digital Fabrication. The hall features strikingly curved walls made of reinforcing bars, some of which are filled with concrete or natural stone. A robotic arm can grip, bend, place and weld the individual bars independently. This makes it possible to construct shapes that would be far too time-consuming and complex to do by hand.

Reinforcement at the touch of a button

The core of MESH's expertise lies in the software that processes the data and calculates the robot's movements. It can generate the reinforcement cage of a free-form concrete wall at the touch of a button and send the data directly to the machine. The complexity of the shape is easy to handle thanks to the direct link between digital data and digital production. “Architects don't normally have any connection to reinforcement,” says Mirjan. “Now they can design with it, as the construction directly influences the shape.”

The MESH technology was used, among other things, to automatically place the reinforcement for the 3D-printed Tor Alva in Mulegns. The flagship project pushes the boundaries of digital fabrication and demonstrates its new formal possibilities. MESH is also focusing on the freedom of form at the Architecture Biennale in Venice, together with Gramazio Kohler Research and the artist Armin Linke. In the Arsenale, the team is presenting an installation consisting of three floating rings made of reinforcing steel, in the middle of which a humanoid robot dreams of the future of digital construction. “How digitalization will change architecture is still an open question,” says research director Inés Ariza, who is responsible for the project.

For variety, against labour shortages

Beyond the Biennale, the reality of construction is still different. “The demand for complex shapes is limited, even if they can save material thanks to optimization,” says Mirjan. MESH has therefore expanded its business model. The spin-off also uses its robots to partially automate the use of conventional reinforcing bars. An automatic stirrup bender machine the size of a bus stands in a corner of the hall. The industry has been using the machine for some time to automatically bend and cut rebar. The robot now replaces the worker, who removes the differently shaped parts and stacks them carefully.

In this way, the startup is counteracting the shortage of labor, especially for such physically demanding jobs. Automation also helps to ensure that individual construction remains affordable. “No two buildings are identical, and the reinforcement of every staircase is slightly different,” says Mirjan. Digital solutions allow this diversity in construction to be maintained even as wages rise. The first MESH robots are being used by reinforcement manufacturers in Switzerland, to whom the spin-off rents out its technology.

Used in the Gotthard Road Tunnel

MESH also uses the robotic arm to identify reinforcing bars, control quality and improve logistics overall. The company has been awarded a major contract for the construction of the second Gotthard road tunnel. Robots knot the reinforcing bars for prefabricated concrete elements at the crossing points. With around 10,000 reinforcement cages, this requires mass production, in which automation can save time and money.

MESH's technology can be used in a variety of ways, from free-form projects to standard prefabrication. The start-up will continue its research and try to open up new business areas. “Special projects such as the Tor Alva or at the Biennale are important to further develop the technology and communicate it to the construction industry,” says Mirjan. “Our innovations should find broad application and make a sustainable contribution to the industry.”

MESH at the Swissbau 2024. (Video: Girts Apskalns)