Pilot Production of Biochemistry Analyser

A medical company sought to develop a new biochemistry analyzer product. Development was stalled due to the complex structure of a component and the small quality required. Then they found RPWORLD to help them get out of the dilemma.

PROJECT BACKGROUND

A medical company sought to develop a new biochemistry analyzer product. Development was stalled due to the complex structure of a component and the small quality required.Then they found RPWORLD to help them get out of the dilemma.

CHALLENGES

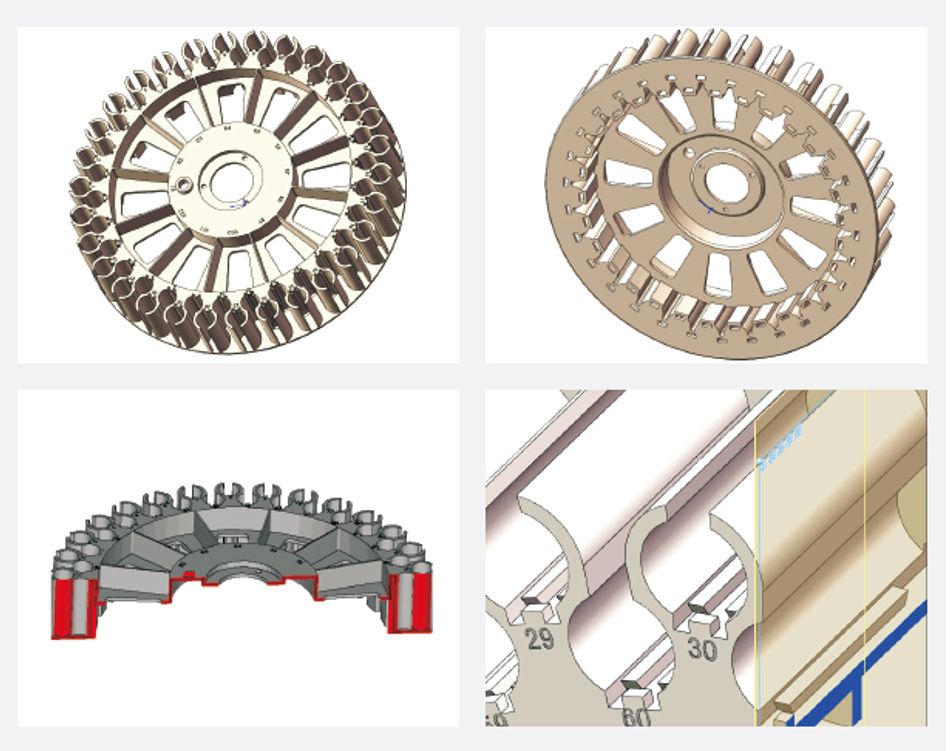

★ Structure too complex for injection molding or CNC milling

★ Production quantity is very low(50 to 500 sets per year)

RPWORLD SOLUTIONS

Processes Chosen

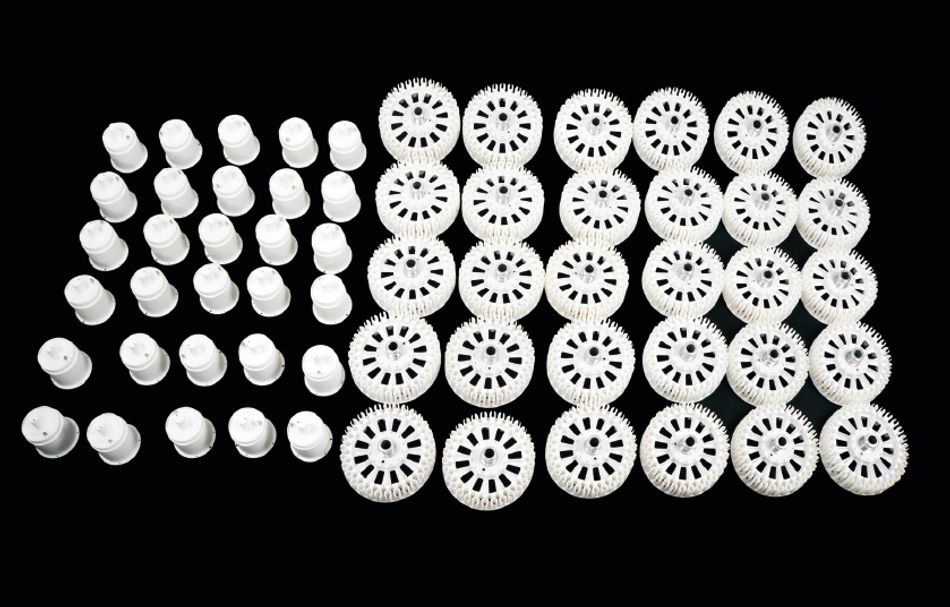

• After meticulous analysis and discussion, we chose SRM(Silicon rubber molding)/vacuum casting/urethane casting.

Material Selection

• To meet cosmetic and performance requirements, ABS performance polyurethane resin was selected. It provided competent mechanical properties, including impact resistance.

Production Schedule

| • Rapid prototyping and testing | 4 days |

| • Silicon rubber molding and testing | 4 days |

| • 50 units manufacturing by vacuum casting | 6 days |

| • After-treatment was done by our experienced technicians | 2 days |

| • Total | 16 days |