Multi-Cavity and Family Molds: How to Choose the Right Mold for Your Injection Molded Project

When designing injection molded parts, multi-cavity and family molds are options worth considering, not just single-cavity tools. But are they the right fit for your injection molded project?

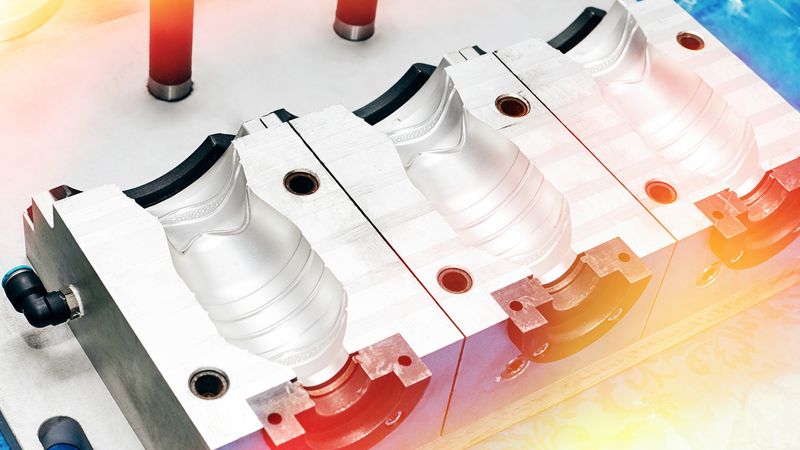

Credit: Shutterstock

When designing injection molded parts, multi-cavity and family molds are options worth considering, not just single-cavity tools. But are they the right fit for your injection molded project? Drawing on more than 20 years of manufacturing experience, here’s a deeper look into the practical considerations behind each option.

1. What are Multi-Cavity and Family Molds

Multi-Cavity Molds: Designed to produce multiple identical parts in one cycle. For example, a 4-cavity tool can produce four identical parts per shot, improving production efficiency and reducing unit cost when demand is high.

Family Molds: Designed with different cavities in a single tool, each cavity forming a distinct part of the same assembly (e.g., housing, cover, and latch). This ensures material and color consistency while reducing tooling count.

While both approaches sound efficient, this payoff depends on volume and tooling investment, which means that more cavities don't always equate to cost-efficiency.

2. Single vs. Multi vs. Family Molds: A Quick Comparison

Single-cavity molds are widely used in early development phases because of their lower upfront cost, shorter build time, and flexibility for design validation.

Multi-cavity molds are often chosen when higher volumes are required, and parts are relatively simple and uniform.

Family molds can produce multiple different parts in one cycle, making them suitable for assemblies or kits — but they involve greater design complexity and cost.

Important: Cavity count is not determined by order size alone. Part geometry, tooling risks, and ROI must also be considered. In some cases, a simpler tool yields better results even at higher volumes. Please check the quick reference table

Factor | Single-Cavity Mold | Multiple-Cavity Mold | Family Mold |

Output per Cycle | 1 part | 2, 4 or 8 identical parts | 2, 4 or 8 different parts |

Per-Part Cost | Highest at any volume | Lowest at scale | Moderate |

Lead Time | Slower for large orders | Fast throughput | Efficient for grouped parts |

Part Uniformity | Consistent | Highly consistent | Varies based on part shape/size |

Tool Complexity | Low | Moderate | High (due to varied fill and gating balance) |

Applications | Prototyping, validation, low volume | Mid- to high-volume of same part | Kits, assemblies with multiple parts |

3. Key Considerations for Mold Selection

3.1 Align Mold Type with Volume & Cost Targets

Low volume: Single-cavity molds are typically preferred for speed and low initial investment.

Medium to high volume: Multi-cavity molds can lower per-part cost and improve throughput — but only when geometry is simple and demand is predictable.

Assemblies with multiple components: Family molds improve material/color consistency by producing parts together but require more complex design and higher upfront cost.

ROI Example:

Single-cavity mold: $10,000 tool + $1.00 per part 10,000 pcs = $20,000 total

4-cavity mold: $30,000 tool + $0.40 per part 40,000 pcs = $46,000 total

3.2 Factor in Part Geometry & Tooling Constraints

Large/complex parts: Better to limit cavity count to simplify design, improve cooling, and reduce risk.

Symmetrical/balanced parts: More suitable for multi-cavity tools as they allow even filling.

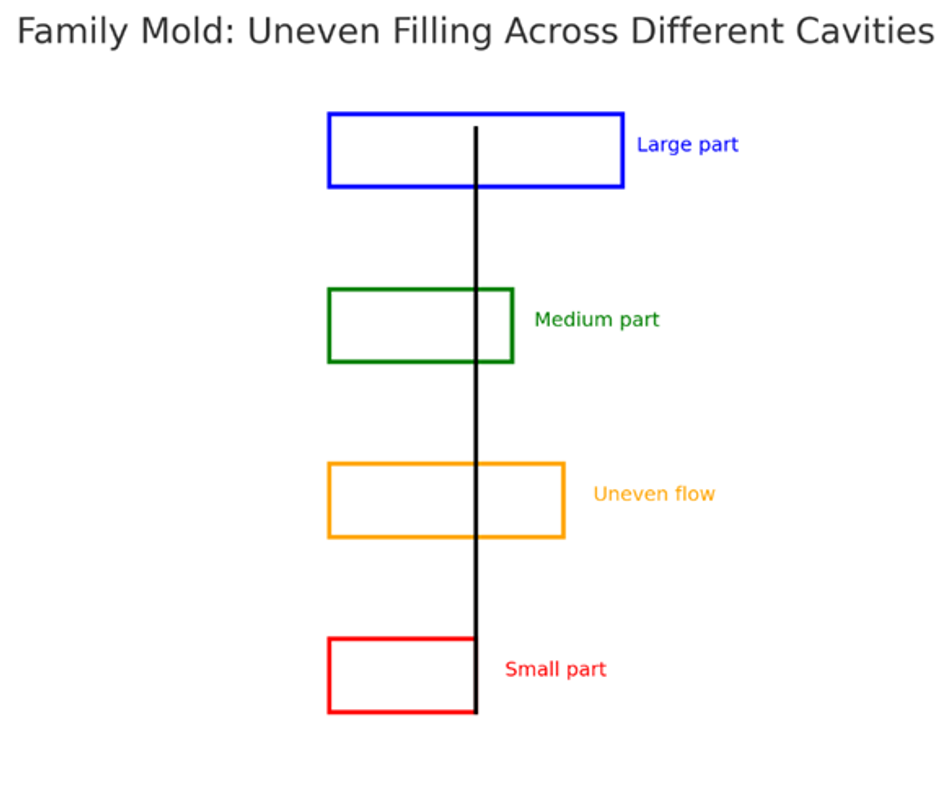

Family molds: Since they include different shapes/sizes in one tool, the mold maker must carefully balance internal pressures with complex gating and runner systems. Often, hot runner technology is needed to control temperature and stress. This adds higher cost and longer preparation time.

Diagram showing how different part sizes in one family mold create uneven filling/pressure, requiring more complex gating and sometimes hot runner systems.

3.3 Think Long-Term: Maintenance & Risk

Multi-cavity molds: More cavities = more maintenance. A failure in one cavity may shut down the entire tool.

Family molds: If one cavity produces defects, the entire cycle may result in wasted material.

4. Industries & Applications Where Both Shine

Multi-cavity and family molds are commonly used across industries where part consistency, cost-efficiency, and production speed matter:

Medical & Healthcare: Ideal for high-precision disposable parts and diagnostic kits where repeatability and volume are key.

Consumer Electronics: Used for enclosures, buttons, and internal supports that require matching materials and tight tolerances.

Automotive: Applied to fasteners, clips, and trim parts—standardized components needed at scale across multiple models.

Industrial & Construction: Suitable for brackets, fittings, and small structural parts where molding multiple components together saves time and cost.

5. Why Partner with RPWORLD for Your Mold Project?

At RPWORLD, we deliver custom injection molding solutions — from low-volume parts to scalable production, tailored to your project’s stage and volume. Here’s how we help accelerate your success:

- Rapid tooling in as little as 7 days, moving from design verification to production parts fast

- Expert DFM support to ensure manufacturability, cost efficiency, and risk reduction

- Flexible mold options: single, multi-cavity and family molds for efficiency and cost-effective

- 100+ engineering-grade materials with RoHS & REACH compliance

- Comprehensive quality assurance: COA, FAI, full inspection reports for every batch

- Scalability from 50 testing parts to 100,000+ production runs

Ready to evaluate your next molding project? Upload your CAD and explore the most efficient path forward with our engineers.