Microminiature Components Are Revolutionizing the Connected Vehicle Industry

Article #4 of our Connected Transport Series. Many technologies, regulations, and infrastructure changes need to be adopted for connected vehicles to realize their full potential.

Image credit: BMW

This is the fourth article in a 5-part series exploring the connectivity solutions for the future of transportation. The series will detail various connectivity challenges engineers face and describe the technology that will provide the solutions to enhance transportation and driving experience.

The articles were originally published in an e-magazine, and have been substantially edited by Wevolver to update them and make them available on the Wevolver platform. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics supports engineers in building a highly connected transport future in addition to knowledge sharing on related topics of electric vehicles, 5G, and autonomous transport.

Introduction

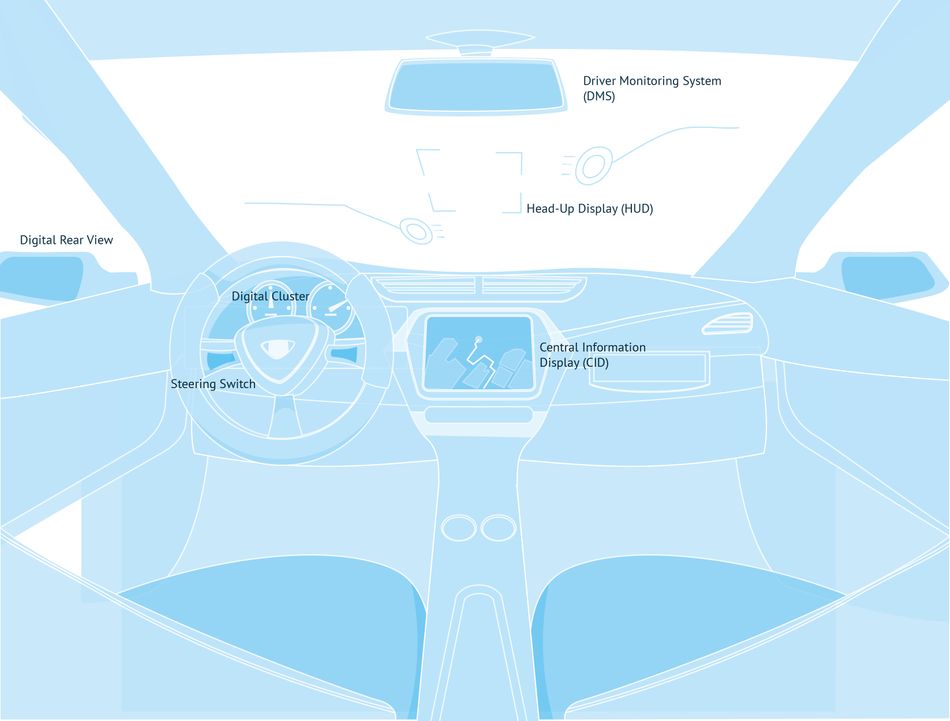

Although the streets are not yet filled with driverless cars, more and more vehicles are being outfitted with the components needed to facilitate higher-level autonomy, and connectivity with networks and devices alike. In concert with state-of-the-art sensors, the capabilities of connected vehicles - span from customized media modules to advanced driver assistance systems (ADAS) that serve as a virtual copilot and beyond.

The anticipated widespread rollout of 5G networks, which will boost connectivity for all internet-enabled devices, and advances in specialized miniature connector systems will continue to facilitate the connected vehicle industry's growth. These advances are sure to revolutionize how consumers and devices interact with vehicles, virtually turning into computer networks on wheels.

Connected vehicle capabilities are not only being integrated into consumer vehicles. Advancements in the technology are being fast-tracked in industries that will benefit the most from data-driven automobiles, such as agriculture and commercial transportation. For example, in 2018, Ford and Walmart partnered to test autonomous grocery delivery in Miami. The test harnessed the benefits of connected technology within commercial areas, in addition to introducing select consumers to a self-driving vehicle and how to interact with it once it arrived at their house. Ford also partnered with Dominos Pizza to further its research in this area.

Meanwhile, manufacturers and other industry players continue to make strides in the fully autonomous vehicle market. Volvo and Mercedes are the latest automakers to team up with tech giants to develop and integrate software into their vehicles, making automotive infrastructure increasingly digital. There are also reports that more than 50 countries have recently agreed to adopt autonomous vehicle regulations issued by the United Nations, further standardizing and quantifying how a world of connected vehicles might operate.

Although it might be a matter of time until fully autonomous vehicles take to the roads, connected vehicles are driving the industry in the right direction by evolving automobile infrastructure to handle connectivity and, eventually, fully autonomous control.

Components Driving Connectivity

Autonomous vehicles require cutting-edge components, creating new challenges for designers and engineers. However, seamless adoption and integration of components that enable self-driving cars - especially when it comes to safety and connectivity - are critical for advancing the industry. The increased electronic content in vehicles requires more connections, more input and output systems, and more data. All of those electronic components will need to communicate seamlessly within vehicle networks.

The types of terminals used by original equipment manufacturers (OEMs) - such as clean body or locking-lance - are often dictated by the region in which they are built. U.S. automakers worked with the United States Council for Automotive Research (USCAR) to establish a 0.5mm terminal. In contrast, German automakers follow Zentralverband Elektrotechnik (ZVEI), which has a different 0.5mm interface with a side-latch design and uses a locking-lance terminal. There is no governing body in China for automotive standards, so automakers are free to choose either North American or European designs already tooled. South Korea is developing its standards, and Japan's major automakers are influenced by parent companies and joint ventures in both North American and European countries.

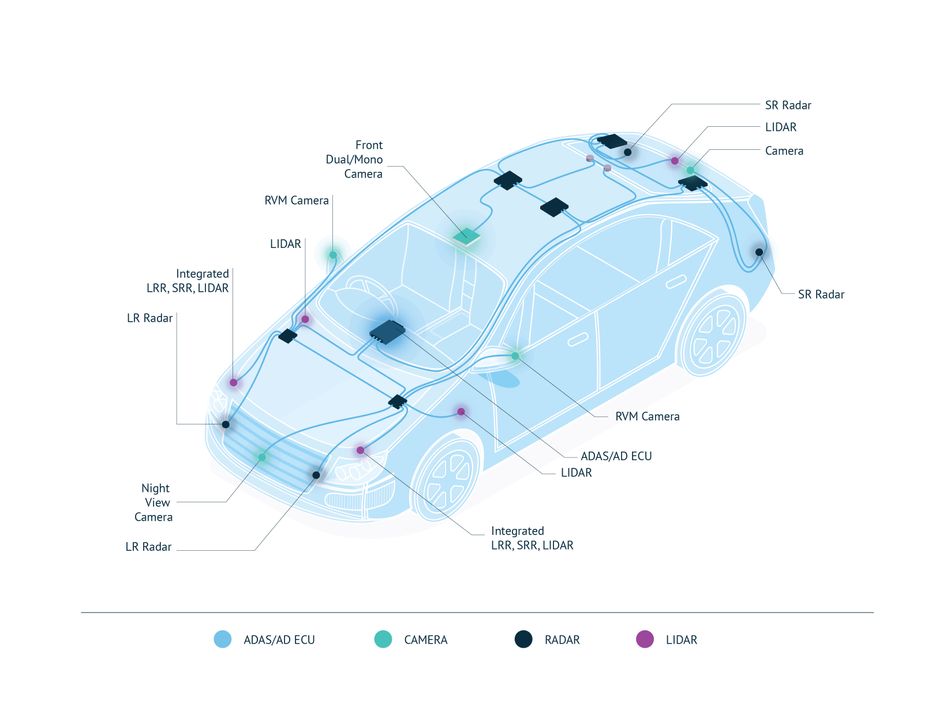

The race to develop driverless vehicles will require additional sensors and more redundancy for safety applications. Consumers will expect a vehicle with 360-degree sight, capable of seeing, anticipating, and operating in any situation, regardless of the harshness of the environment. Customers will also expect a highly capable, customized experience, which will result in the vehicle running more applications and putting more sophisticated demands on vehicular networks.

Connected vehicles need reliable internet connections, and components must communicate vast amounts of data with many different sources, both inside and outside the vehicle. These hefty connectivity requirements call for denser packaging of in-vehicle electronics across a wide variety of ever-increasing applications. Designers must fit more circuits into smaller spaces while maintaining the same robust automotive requirements.

These trends call for smaller connector systems that use smaller wire to fit the dense packaging needs. In response, designers have increasingly shifted over the past few years to using 0.5mm terminal systems, customized depending on who is using the terminals and in what capacity.

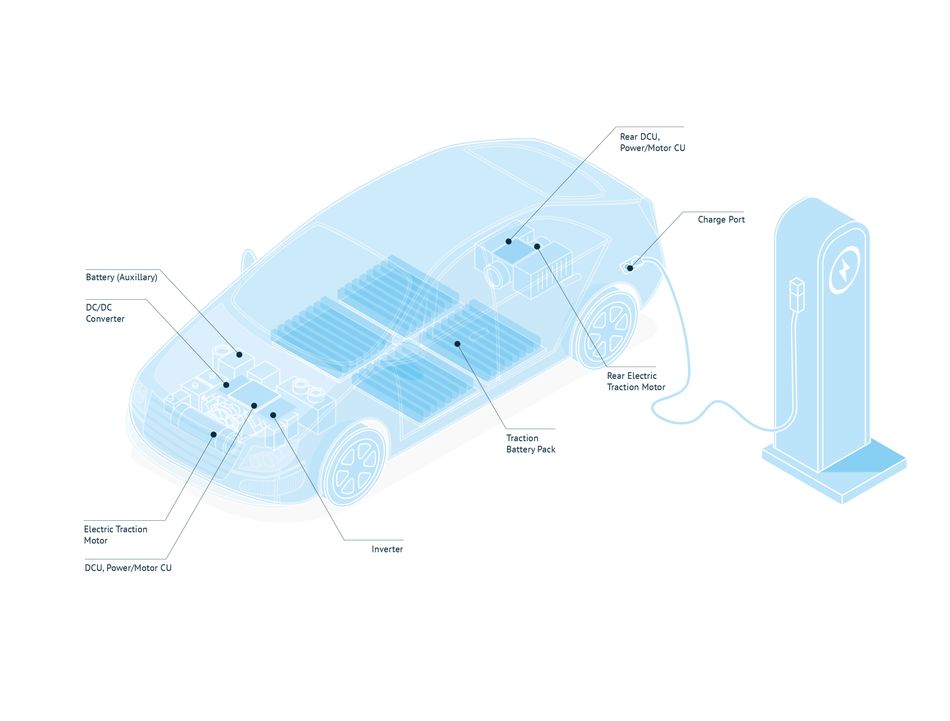

Space-Saving Challenges

Creating a line of connectors that meet USCAR and ZVEI requirements while solving some of the toughest challenges presented by connected vehicle specifications requires a team of experienced, dedicated designers. Beyond engineering a line of connectors that meet regional requirements, other design challenges are emerging as manufacturers streamline connected vehicle connectivity. For example, a continued push for weight savings in the vehicle has affected the connector industry and calls for smaller wires and more compact wiring bundles. Hybrid electric vehicles (HEV) and battery electric vehicles (BEV) continue to drive this trend with complex battery management systems with massive amounts of connections and wiring packaged in a small space. This challenge creates the need for solutions that are not traditional to automotive applications, such as micro-sized connectors, very small wire gauges, and flexible flat cables (FFCs).

As the HEV and BEV markets increase vehicle lifespans from a traditional 320,000km (200,000 miles) to 1.6-million km (1-million miles), there is an increased need for connection systems and terminal contact interfaces that can withstand temperature and vibration over this extended period. Regardless of engine type, whether traditional internal combustion engine, HEV, or BEV, the need for more I/Os near the engine and in harsh environments is increasing. Engine controllers have evolved to become sophisticated computers that are sending and receiving data throughout many systems in the vehicles. Additionally, the transition to smaller systems is also happening with engine controllers as requirements for circuit counts reach more than 300 in such systems. Smaller wires and terminal systems create challenges in operating in environments with higher temperatures and vibration.

The Mini50 and TAK50 Solutions from Molex

Innovation on new 0.5mm products has been a focus for Molex, which has honed its line of Mini50 connectors to meet the needs of OEMs through elegant design and a deep understanding of the unique - and continuously evolving - requirements within the connected vehicle market.

Understanding that customers' preferences differ, Molex has enhanced the 050 offerings to include TAK50, which provides various options across its standard product lines:

- Mini50 Connection System - USCAR-standard unsealed interface - clean-body terminal and top-latch design: (Figure 4)

- Offers 50 percent space savings over traditional 0.64mm systems

- Tested to USCAR and LV214

- Multiple configurations and circuit sizes

- Mini50 Sealed Connection System–one of the smallest automotive-grade sealed connector systems that meet USCAR-2 specifications for automotive electrical connector systems:

- Offers 50 percent space savings over traditional 0.64mm systems

- ConnTAK50 Connector System–German auto standard 050 interface–locking-lance terminal, side-latch design:

- Tested to USCAR, PSA, and LV214 specifications

- Also offers a clean-body terminal option

- stAK50h Connection System–Hybrid stackable header and connector system that offers 0.5mm, 1.2mm, and 2.8mm options:

- The system provides four customized header designs that can be stacked together to make multi-bay headers.

The use of the Mini50 Connector System delivers significant space savings over the traditional USCAR 0.64mm connectors while eliminating mating and assembly errors and offers protection from water and dust with Mini50 Sealed. Additionally, the Mini50 Connector System is selected as the industry's USCAR 0.50mm unsealed interface. These solutions power essential connected vehicle components such as mirrors and cameras, sensors, power steering and braking, and more.

The Mini50 Connector System is also used in commercial vehicle applications. Ruggedization of components is critical in commercial and agricultural vehicles, and the Mini50 line of connectors is designed to withstand harsh environments common in the commercial sector. And as more commercial vehicles are being built to run on electricity, Molex's connectors will enable the integration of clean, secure electrical systems.

In addition to miniaturization in both consumer and commercial vehicles, there is still the need for a variety of other connectors and terminal types throughout the vehicle. Molex also has a wide variety of standard offerings that solve customer challenges every day. Products such as MX150, Stac64, MX64, Duraclick, CMC, and Mizu25 connectors are longstanding standards released at multiple global OEMs and used in vehicles all over the world.

Summary

Many technologies, regulations, and infrastructure changes need to be adopted for connected vehicles to realize their full potential; electrical component developers must work alongside auto manufacturers to develop cutting-edge, microminiature solutions that will enable connected vehicles to reach their full potential and, eventually, pave the way for a fully automated future.

This article was originally published by Mouser and Molex in an e-magazine and substantially edited by the Wevolver team. It's the fourth article of a 5-part series exploring connectivity solutions for the future of transportation.

The first article examined how the 5G network will deliver Connected Cars.

The second article discussed connected transport and automotive ethernet.

The third article introduces the modularity challenges of Connected Cars.

The fifth article looked at connectivity requirements for ADAS.

About the sponsor: Mouser

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

Resources and further reading:

[Internet]. 2021 [cited 27 May 2021]. Available from: https://corporate.walmart.com/newsroom/2018/11/14/walmart-and-ford-to-test-grocery-delivery-with-self-driving-cars

2. Waymo and Daimler are teaming up to build fully driverless semi trucks [Internet]. The Verge. 2021 [cited 27 May 2021]. Available from: https://www.theverge.com/2020/10/27/21536048/waymo-daimler-driverless-semi-trucks-cascadia-freightliner

3. Volvo Cars brings infotainment system with Google built in to more models [Internet]. Media.volvocars.com. 2021 [cited 27 May 2021]. Available from: https://www.media.volvocars.com/global/en-gb/media/pressreleases/279230/volvo-cars-brings-infotainment-system-with-google-built-in-to-more-models

4. Automated vehicles – EURACTIV.com [Internet]. Euractiv.com. 2021 [cited 27 May 2021]. Available from: https://www.euractiv.com/sections/automated-vehicles/

5. [Internet]. 2021 [cited 27 May 2021]. Available from: https://eu.mouser.com/new/molex/molex-mini50/