Microfocus X-Ray Sources for Li-ion Batteries: High-Resolution Inspection from Cylindrical to Prismatic Cells

This article examines the application of MFX source technology in inspecting cylindrical, pouch, and prismatic battery cells, highlighting its technical advantages, integration capabilities, and the increasing need for such inspections in modern manufacturing environments.

Introduction

The burgeoning landscape of energy storage, driven in part by the demand for electric vehicles (EVs) and portable electronics, places an unprecedented emphasis on battery quality and reliability. To ensure quality and improve product safety and yield, X-ray inspection has become a standard requirement in manufacturing processes. In this context, Microfocus X-ray (MFX) source technology has emerged as a pivotal tool in non-destructive battery inspection across various types of battery cells. These systems combine high-resolution performance with easy integration and continuous operation, making them especially suitable for inline inspection in large-scale battery production.[1]This article examines the application of MFX source technology in inspecting cylindrical, pouch, and prismatic battery cells, highlighting its technical advantages, integration capabilities, and the increasing need for such inspections in modern manufacturing environments.

Adaptable Inspection Across Cylindrical, Pouch, and Prismatic Cells

The diversity in battery cell designs means each presents unique manufacturing challenges and inherent vulnerabilities. Cylindrical cells, with their robust metal casings, are widely adopted but still susceptible to winding defects. Pouch cells, prized for their flexible and lightweight design, are inherently delicate, making internal integrity particularly critical [1].

Prismatic cells, offering excellent space efficiency, require precise alignment of their layered components. MFX sources excel in their ability to inspect all these battery types non-destructively, delivering a consistent and reliable quality control solution across the entire spectrum of battery production. This versatility means a single platform can cater to diverse product lines, streamlining inspection processes and reducing the need for specialised equipment for each cell format.

Unveiling Micro-Anomalies with Precision Spot Size

A defining feature of MFX technology is its exceptionally small focal spot size, often less than 100 µm [1]. This attribute is crucial for achieving high-resolution imaging, allowing for the detection of minute defects that could compromise battery performance or safety.

The ability to resolve fine details is critical when assessing parameters such as anode-cathode separation and electrode alignment. Accurate measurement of these aspects ensures optimal electrochemical performance and mitigates risks associated with short circuits or thermal runaway.

In addition, high-resolution imaging enables the detection of microscopic foreign particles, potential initiation points for dendrite growth and internal shorts, as well as the verification of proper cell positioning within battery modules, which is vital for mechanical stability, thermal regulation, and electrical connectivity. MFX technology provides the precision necessary to carry out all these inspections reliably, supporting both safety and longevity in battery design.

Simplified System Integration with True Mono-Block Design

Beyond its exceptional imaging capabilities, MFX technology distinguishes itself with a true mono-block design. The mono-block design of MFX sources simplifies integration into existing production lines. This compact configuration minimises the need for extensive system modifications, enabling straightforward installation and maintenance. Moreover, the sealed nature of these units minimises the risk of contamination and enhances operational safety [2].

Versatile Imaging Capabilities

MFX technology offers a versatile suite of imaging modalities for both 2D and 3D analysis. Each is engineered to address specific inspection requirements within battery manufacturing. This adaptability ensures that manufacturers can tailor their inspection approach to meet the complexity, scale, and precision required for each stage of production. 2D linear imaging is ideal for high-speed, continuous scanning on production lines, making it well-suited for detecting large-scale anomalies or inconsistencies across the length of battery cells, particularly during initial quality screening. A conceptual example of in-line cylindrical LiB is shown in Figure 1.

For more targeted internal assessments, laminography provides detailed, layer-by-layer visualisation, allowing engineers to uncover defects such as voids, delaminations, or misalignments within stacked electrode layers that may be concealed in traditional 2D projections. At the highest level of detail, 3D imaging enables comprehensive volumetric reconstruction of the battery’s internal architecture. This is crucial for complex defect analysis and advanced R&D, as it reveals subtle structural inconsistencies such as uneven winding in cylindrical cells or multi-layer delamination in pouch designs.

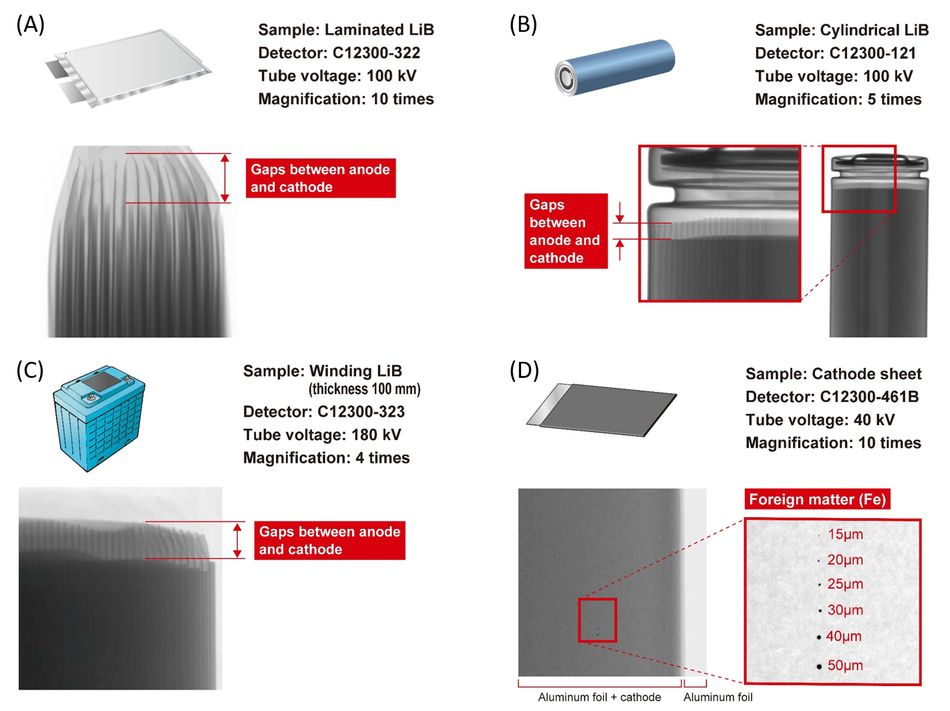

Support for all three modalities — linear, laminographic, and 3D —allows MFX systems to empower manufacturers in selecting the most effective imaging technique for each application, ensuring maximum inspection accuracy while maintaining production efficiency. High-resolution X-ray imaging of lithium-ion batteries is made possible by Hamamatsu’s MFX sources paired with advanced detectors, which provide clear visualization of internal structures across various cell formats. As shown in Figure 2 , these systems successfully reveal defects such as gaps between anode and cathode layers, layer misalignment, and foreign particle contamination as small as 15 µm in anode/cathode sheets. This level of detail enables manufacturers to detect potential failure points early in the production process, ensuring higher yields, improved safety, and extended battery life [2,3,4].

The Role of Detectors in High-Precision MFX Imaging

While MFX sources provide the high-resolution X-ray beam, the performance of the entire inspection system critically depends on the detector. For high-speed 2D inspection tasks, Hamamatsu’s time-delayed integration (TDI) cameras are widely used for their ability to capture fine structural changes in real time, thanks to their 48 µm pixel size and capability to acquire distortion-free images of moving objects.

For 3D volumetric imaging, especially cone-beam CT applications, the newly developed Flat Panel Sensor C16401SK-51 provides high spatial resolution, fast readout, and is designed specifically for advanced Li-ion battery inspection. This detector enables precise reconstruction of internal battery architecture, supporting defect analysis during both R&D and production [5].

Proven Track Record and Growing Adoption

MFX technology has established a substantial installed base across a wide range of industries, reflecting its proven reliability, accuracy, and adaptability in demanding inspection environments. In battery manufacturing specifically, its deployment has grown steadily as manufacturers seek robust, non-destructive solutions capable of meeting the high standards of precision required for modern energy storage systems. Companies have successfully integrated their MFX systems into high-throughput production lines, demonstrating the technology’s maturity, ease of integration, and consistent performance under real-world manufacturing conditions.

These case studies highlight not only the technical advantages of MFX systems but also their long-term operational stability and minimal maintenance demands. As the battery industry continues to evolve, driven by electric mobility, grid-scale storage, and portable electronics, the adoption of MFX inspection solutions is expected to accelerate further, fuelled by the growing emphasis on quality assurance, yield optimisation, and regulatory compliance across the global supply chain [1].

Localization Drives Inspection Innovation in EU Gigafactories

The current global geopolitical climate and supply chain vulnerabilities are accelerating the trend towards localised battery production. However, while the trend toward localized battery production remains a strategic priority, several Gigafactory projects across the EU have encountered delays, restructuring, or shifts in investment focus due to evolving market and financial conditions. Despite these challenges, the underlying need for flexible, high-performance inspection technologies like MFX is growing. As production moves closer to assembly facilities, local manufacturers must assume full responsibility for quality control, from raw materials to finished cells, without relying on distant quality assurance checkpoints.

Robust internal inspection becomes essential to mitigate risks within the supply chain and prevent costly disruptions. Additionally, compliance with stringent regional regulations, particularly in the EU, requires thorough and traceable inspection processes to ensure that safety and environmental standards are met. Localised production also fosters innovation, with more customised chemistries and cell designs emerging from regional R&D efforts. MFX technology, with its flexible imaging capabilities, supports this by enabling precise evaluation of new structures and materials. Finally, real-time inspection within domestic facilities shortens feedback loops, allowing for immediate corrective action and continuous optimisation of production processes.

Industry Spotlight: Hamamatsu’s Precision Imaging for Battery Inspection

Among the leading innovators in MFX technology, Hamamatsu Photonics, backed by decades of photonics expertise, has distinguished itself with microfocus X-ray sources engineered for high-precision battery inspection. Their MFX sources enable ultra-high-resolution imaging of internal battery structures down to 0.25 µm resolution.

This level of detail is crucial not just for detecting standard manufacturing defects but for identifying microscopic anomalies, such as filamentous dendrite precursors or misaligned separator layers, that can be easily overlooked with conventional imaging tools.

Designed with manufacturability in mind, Hamamatsu’s sealed-type MFX sources offer a compact, mono-block architecture that simplifies integration into existing production lines. The sealed design also reduces potential contamination risks and minimizes the need for frequent servicing, ensuring high system uptime — a key requirement in continuous, high-throughput environments like Gigafactories.

In real-world deployments, Hamamatsu’s systems have been praised for their consistency, reliability, X-ray emission stability and minimal maintenance overhead, enabling manufacturers to conduct critical quality inspections without slowing down production. Their proven track record across multiple industries further validates the robustness of their MFX solutions as manufacturers scale up and diversify battery designs.

Conclusion: MFX as a Cornerstone of Battery Quality Assurance

As the battery industry accelerates toward higher energy densities, faster production cycles, and localized Gigafactory ecosystems, quality assurance can no longer be an afterthought; it must be embedded into the core of manufacturing. Microfocus X-ray (MFX) sources technology offers a uniquely powerful solution, combining high-resolution, non-destructive imaging with flexible integration and modality options tailored to every cell architecture.

With industry leaders like Hamamatsu pushing the boundaries of precision and reliability, offering ultra-fine focal spot sizes and systems optimized for high-throughput environments. MFX inspection is quickly becoming a benchmark for safe, efficient, and scalable battery production. From early-stage R&D to mass production lines, MFX systems enable manufacturers to detect the smallest internal defects, reduce waste, and continuously refine their processes.

In an era where even the tiniest flaw can compromise the safety of a vehicle or a device, internal battery integrity is no longer optional; it’s mission-critical. MFX sources technology powers a brighter, safer electrified future.

For further technical details, the 2025 Hamamatsu MFX X-ray Sources Catalog offers a complete overview of available sealed and open-type systems.

References:

- Hamamatsu Photonics. (n.d.). X-ray Imaging Questions & Answers [Online]. Available: https://hub.hamamatsu.com/us/en/ask-an-engineer/imaging/x-ray-imaging-questions-and-answers.html

- Hamamatsu Photonics. (2025). Microfocus X-ray Sources Catalog.

- Hamamatsu Photonics K.K., Lithium-ion Battery Inspection. [Online]. Available: https://www.hamamatsu.com/us/en/applications/industrial-x-ray-ndt-inspection/lithium-ion-battery-inspection.html

- S. Kumari, “How advanced X‑ray and inspection technologies are powering safer, smarter Gigafactory batteries,” The Battery Magazine, May 20, 2025. [Online]. Available: https://www.thebatterymagazine.com/how-advanced-x-ray-and-inspection-technologies-are-powering-safer-smarter-gigafactory-batteries/

- Hamamatsu Photonics, “C16401SK-51: X-ray flat panel sensor,” Hamamatsu Photonics, [Online]. Available: https://www.hamamatsu.com/jp/en/product/optical-sensors/image-sensor/x-ray-flat-panel-sensor/C16401SK-51.html