Maximizing APSX-PIM Capabilities: Unleashing Freeform Injection Molding (FIM) with Nexa3D Printers

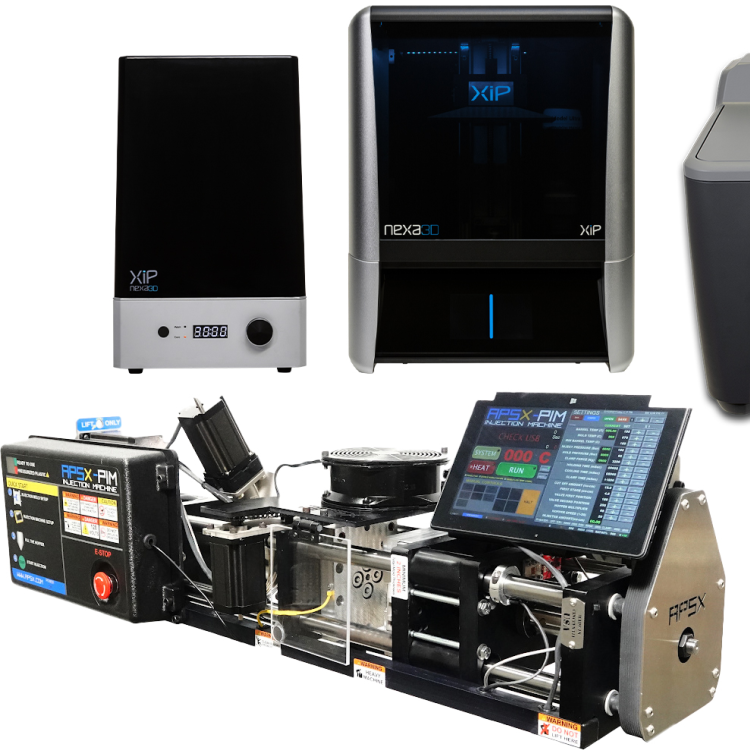

We invite you to explore the convergence of traditional injection molding with the cutting-edge realm of Freeform Injection Molding (FIM) using Nexa3D printers, which promises to revolutionize your production capabilities.

Innovation in manufacturing is a continuous journey, and as APSX-PIM owners, you stand at the forefront of this evolution. Today, we invite you to explore the convergence of traditional injection molding with the cutting-edge realm of Freeform Injection Molding (FIM) using Nexa3D printers, which promises to revolutionize your production capabilities.

Elevating Precision, Speed, and Complexity

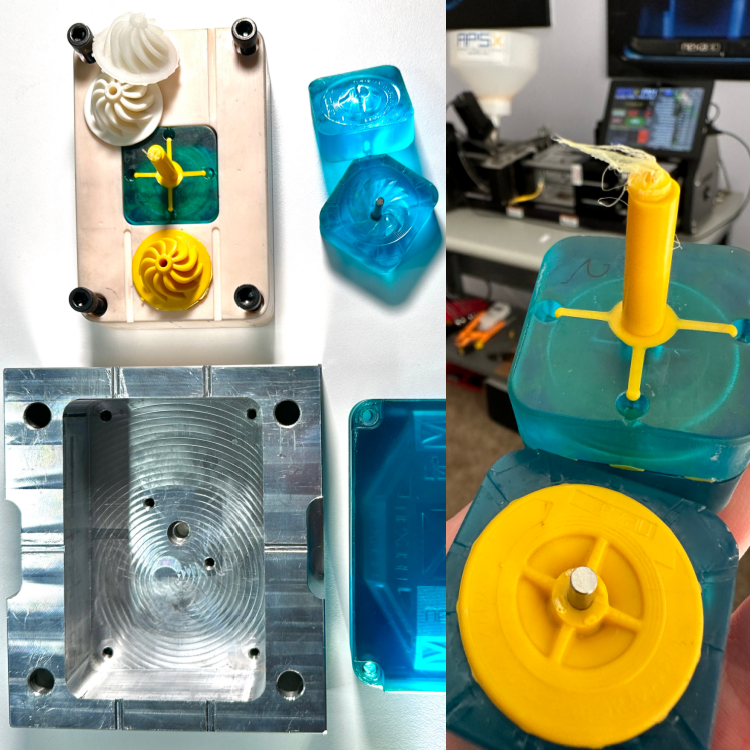

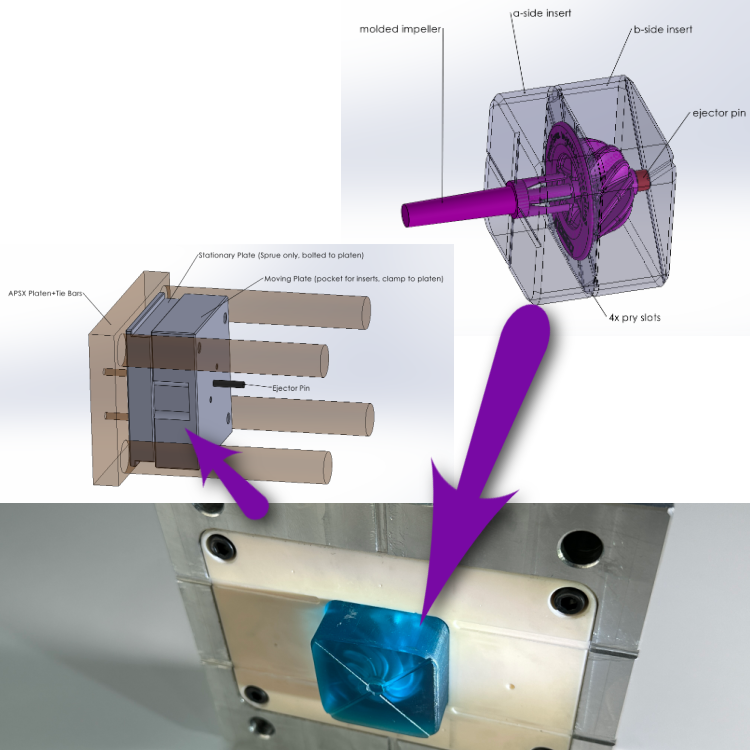

Nexa3D printers stand out for their unparalleled precision and ability to produce intricate parts with unparalleled complexity. This technology opens doors to creating molds with finely detailed features, delicate textures, and intricate geometries, previously unattainable using conventional methods.

Case Study: Automotive Industry

Consider the automotive sector, where the demand for lightweight, intricately designed parts is ever-increasing. With FIM, APSX-PIM owners can swiftly iterate and manufacture complex molds for vehicle components, reducing lead times and enhancing design innovation.

Rapid Prototyping and Iteration: Catalyzing Innovation

One of the hallmark advantages of integrating Nexa3D printers with APSX-PIM is the ability to accelerate prototyping and iteration cycles. This synergy empowers manufacturers to swiftly test new designs, modify molds in real time, and refine prototypes iteratively.

Case Study: Medical Devices

In the medical device industry, speed to market can be critical. FIM allows for rapid prototyping of intricate molds, facilitating the development of medical-grade components with precise specifications, and ensuring compliance and efficacy.

Cost-efficiency and Material Optimization

FIM with Nexa3D printers offers not just agility but also cost-efficiency. Additive manufacturing capabilities minimize material waste by utilizing only the necessary resources for each mold iteration, aligning with sustainability goals and reducing production costs.

Case Study: Consumer Electronics

In the world of consumer electronics, where design and functionality converge, FIM enables APSX-PIM owners to create molds for intricate casings, connectors, and components, optimizing material usage while ensuring high precision.

Seamless Integration: Streamlined Workflow

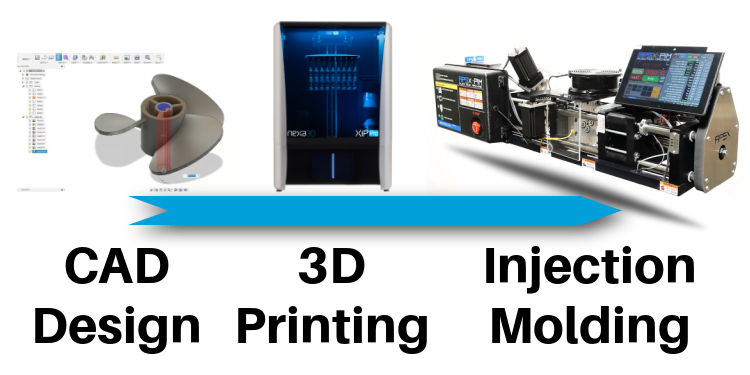

The integration process between Nexa3D printers and APSX-PIM machines is seamless. From designing parts using CAD software to printing molds with Nexa3D and utilizing them in APSX-PIM for injection molding, the workflow is intuitive, enabling a streamlined and efficient manufacturing process.

Visual Representation of the FIM Process

Embrace the Future of Manufacturing Today!

APSX-PIM owners possess the fundamental tool for precision injection molding. By harnessing the capabilities of Nexa3D printers for FIM, you are poised to expand your manufacturing horizons, unlocking unlimited design possibilities, speed, and efficiency.