Maintenance Tips For Industrial Control Panels

Control panels have become a key feature in automation over the last few decades and are of great benefit to the industry. They make your facility easier to run, achieve better performance and are more cost-effective.

This article was first published on

www.rowse-automation.co.ukHowever, to achieve that, you need to ensure that industrial control panels (ICP) are correctly installed and follow a regular maintenance programme to keep them in optimum condition.

To prevent lengthy disruptions, unnecessary downtime and possibly extensive repairs, you can follow the ICP maintenance tips in this article. We’ll be discussing best practices and suggest how best to keep your control panel at peak performance.

Industrial Control Panel Maintenance Tips

There are several ways to set up and maintain your control panel for optimal performance, including:

Allowing it sufficient space

Selecting the right enclosure

Component labelling

Accurate documentation

Heat management

Preventive maintenance

Sufficient Space For Your Panel

All too often, you’ll find that an ICP has been installed in a confined space, making it much harder for maintenance technicians or repair crews to work on. This means that repairs or even regular maintenance will take much longer than necessary. Best practice recommends that you allow as much space as you can when setting up ICPs. This will allow better access for both exterior and interior activities. Maintenance crews and operators should be able to move freely around the panel and you can plan the layout of your facility around it for better overall performance.

If you provide sufficient space for your ICP, all the parts will fit comfortably inside, and the panel can be attached with properly sized cable ducting. Another bonus is that you’ll have adequate space for any expansion you might consider in the future.

Selecting The Correct Enclosure

You’ll only achieve the best performance for your ICP when you house it in a correctly sized enclosure. Also consider the environment in which it will be situated, as there are various designs and materials. For example, in non-corrosive or dry environments, you’ll do fine with mild steel, while more extreme or demanding environments like clean rooms might require stainless steel enclosures. Stainless steel is capable of withstanding a wide variety of destructive elements and is ideally suited to the industrial environment.

Component Labelling

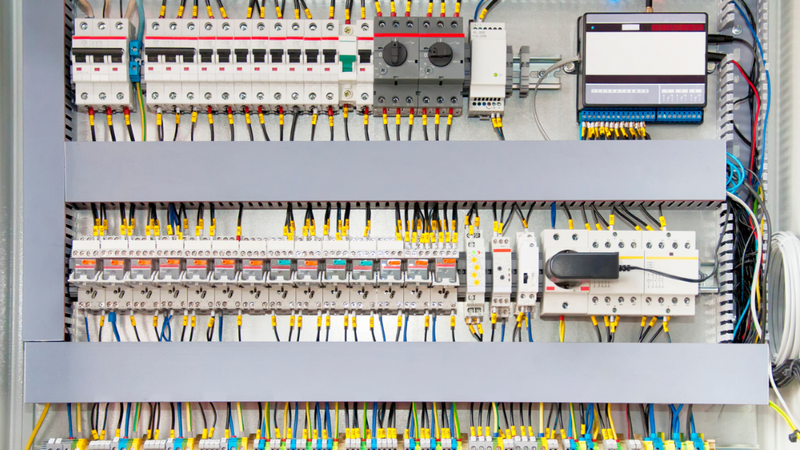

It will be easier to maintain and repair your ICP if you organise and label its wiring and components. You can organise wiring efficiently using duct tap and running cables vertically or horizontally rather than diagonally. Set up the internal layout of your ICP so that you can use short wires wherever possible instead of long ones.

Logical and consistent labelling is very important for ICPs complying with UL 508A. Technicians will be able to work more efficiently on troubleshooting when they can identify all components, so they’ll be able to solve problems quickly and make any necessary modifications. Best practice is to make all labels easily visible, simple and consistent. If you don’t already have one, devise a coherent labelling system for your ICP and follow it consistently.

Wiring

Don’t clutter up the labels with too much information, but identify where each wire or cable comes from and goes to.

Hardware

For any connected hardware such as network equipment, programmable logic controllers (PLCs) or radios, you’ll need to state their IP addresses and, if necessary, the hardware voltage or amperage.

Main Panel

You should label the main panel with information including input voltage, full load amps, fuse legend and short circuit rating. Make sure to match the wire labels to the wiring diagrams.

Accurate Documentation

Accurate documentation is a key factor in optimising your ICP’s performance. If you have inadequate documentation or keep only superficial records of maintenance activities, you might regret it later. You’ll need functional specifications to make any necessary repairs or modifications and save costly errors. Some other documents you’ll need include electrical schematics, program copies and panel drawings. Make sure you have all the information you need to troubleshoot problems and carry out scheduled maintenance. In addition, make a log of any changes you make to the ICP, including alterations and scheduled servicing.

Keeping Your ICP Cool

There are several ways you can prevent overheating in your ICP. For instance, you can install a device to monitor the temperature so you’ll be alerted if it begins to overheat. You’ll be able to adjust the system before the heat reaches dangerous levels. You can help to keep temperatures in your panel consistent by fitting an interior fan or air conditioning unit. If you choose AC, make sure it has sufficient capacity for the enclosure size. You need adequate ventilation and regular cleaning out of dirt and dust, as clogged vents and filters can quickly overheat your system.

Preventive Maintenance

Maintenance is always a critical factor in ensuring that any industrial equipment runs properly. Proactive ICP maintenance can help avoid unnecessary downtime, prolong equipment life, and mitigate any potentially hazardous situations. Establish a regular maintenance schedule and consider building a professional relationship with experts who can come in to inspect your ICP and advise on any necessary action.

Regularly scheduled maintenance should include replacing worn components, tightening loose connections, fixing frayed or faulty wiring and eliminating dust or debris. When carrying out any repairs or adjustments, make sure all the electrical components are properly grounded and clear away all debris with a vacuum or compressed air.

Keeping Your Industrial Control Panel In Peak Condition

Once you’ve installed your ICP correctly and set up a regular maintenance programme, you only need to keep an eye on the schedule and watch out for any unusual activity that might lead to unplanned downtime. An ICP that has plenty of space, an appropriate enclosure and coherently organised components should perform well without continuous oversight.

However, if you do run into any problems, or wish to consult on any aspect of installing and maintaining an industrial control panel, please don’t hesitate to call on our experienced team members at Rowse Automation.