Injection Molding Solutions for High Precision Consumer Electronics Enclosures and Housings

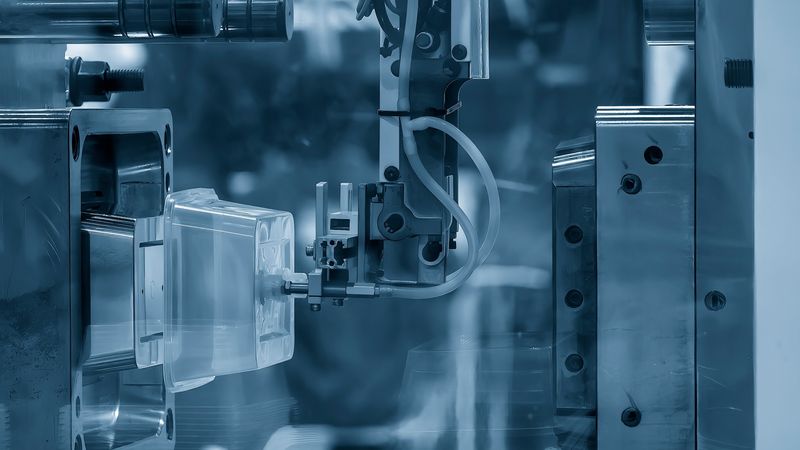

Injection molding has become the preferred manufacturing method for producing high precision consumer electronics enclosures at scale. With advanced capabilities and proven expertise, RPWORLD delivers reliable manufacturing solutions that meet the demanding standards of modern electronics brands.

The consumer electronics industry is driven by innovation, compact design, and flawless performance. From smartphones and smart home devices to wearable technology and audio equipment, enclosures and housings play a vital role in both functionality and aesthetics. These components must protect sensitive internal electronics while maintaining a sleek appearance and precise fit. Injection molding has become the preferred manufacturing method for producing high precision consumer electronics enclosures at scale. With advanced capabilities and proven expertise, RPWORLD delivers reliable manufacturing solutions that meet the demanding standards of modern electronics brands.

Importance of Precision in Electronics Enclosures

Consumer electronics housings require tight tolerances to ensure accurate assembly and long term durability. Even minor dimensional variations can lead to poor fit, misalignment, or compromised performance. Injection molding enables the production of complex shapes with exceptional dimensional accuracy and repeatability. This precision ensures that enclosures integrate seamlessly with internal components such as circuit boards, connectors, and displays.

By offering custom injection molding solutions, manufacturers can tailor designs to meet specific functional and aesthetic requirements. This approach supports innovation while ensuring consistency across high volume production runs.

Material Selection for Performance and Aesthetics

Material choice is a critical factor in electronics enclosure manufacturing. Components must provide strength, heat resistance, electrical insulation, and impact protection while maintaining a refined surface finish. Injection molding supports a wide range of engineering plastics suited for electronic applications, allowing manufacturers to balance performance and design goals.

Through custom plastic molded parts for electronics, RPWORLD helps brands select materials that meet durability requirements while supporting lightweight construction and premium appearance. Surface textures, colors, and finishes can be precisely controlled to align with product branding and user expectations.

Design Flexibility and Functional Integration

One of the key advantages of injection molding is its ability to integrate multiple design features into a single component. Snap fits, ventilation openings, mounting points, and cable management features can be molded directly into enclosures, reducing the need for secondary operations. This design flexibility leads to simplified assembly processes and improved product reliability.

Custom injection molding solutions also allow electronics manufacturers to refine designs for compactness and efficiency. As devices continue to shrink in size while increasing in functionality, precise molding becomes essential to maintain structural integrity without adding unnecessary bulk.

Consistency and Scalability in Mass Production

Consumer electronics often require large scale production with consistent quality across thousands or millions of units. Injection molding provides a repeatable process that ensures uniformity from the first part to the last. Advanced tooling and controlled production environments help minimize defects and maintain strict quality standards.

RPWORLD supports scalability by offering end to end manufacturing services, from prototyping and tooling to full production. This enables electronics brands to move quickly from concept validation to mass manufacturing without compromising quality or design intent.

Quality Control and Manufacturing Expertise

Quality assurance is essential in electronics manufacturing, where enclosures must protect sensitive components from environmental factors such as heat, dust, and impact. Injection molding processes incorporate inspection systems and process monitoring to ensure that each component meets defined specifications.

RPWORLD applies strict quality control measures throughout the production cycle. By combining engineering expertise with advanced manufacturing equipment, the company delivers custom plastic molded parts for electronics that meet performance, durability, and aesthetic expectations.

RPWORLD as a Strategic Manufacturing Partner

RPWORLD is a trusted provider of injection molding services for the consumer electronics industry. With extensive experience in high precision molding, the company helps brands develop and manufacture enclosures and housings that align with modern product demands. Their commitment to innovation, quality, and customer collaboration ensures optimized outcomes for every project.

By leveraging custom injection molding solutions, RPWORLD supports electronics manufacturers in achieving efficient production, reduced costs, and superior product quality.

Conclusion

Injection molding plays a critical role in the production of high precision consumer electronics enclosures and housings. Its ability to deliver accuracy, design flexibility, and scalability makes it ideal for modern electronic products. With expert support from RPWORLD, brands can confidently manufacture custom plastic molded parts for electronics that combine performance, durability, and refined aesthetics, enabling them to succeed in a highly competitive market.