How to pick the right battery for an IoT device: A waste management case study

Once the first prototype of your IoT device becomes available, it is essential to start power profiling and estimating battery life. This process involves gaining a comprehensive understanding of the device's configuration and power consumption characteristics within its specific deployment context.

Consider the following details when conducting power profiling:

- Hardware and sensor configurations: Analyze the components and sensors used in the device and their power consumption characteristics. Understand how different hardware configurations impact energy usage.

- Firmware settings: Examine the firmware settings and configurations to identify any potential areas where power consumption can be optimized. Adjust settings and parameters to achieve more efficient power usage.

- Communication parameters: Evaluate the communication parameters used by the device, such as transmission frequency and data rate. Analyze how different communication settings affect power consumption and battery life.

- Use cases and corner cases: Consider the different use cases and scenarios in which the device will be deployed. Investigate how the device's behavior and power consumption vary under different conditions. Pay special attention to corner cases that may have unique power consumption patterns.

Continuous benchmarking is crucial throughout the product development process. Utilize UART clever printouts and correlate them with power consumption to identify specific components or features that may be draining energy. This analysis will provide valuable insights on areas that can be optimized for improved power efficiency. Remember to turn off UART once the analysis is complete to avoid any impact on the final product.

Additionally, consider network variables that can impact power consumption. Import network log files to understand how factors like distance to the gateway or Node B, weather conditions, and device density within the network influence power consumption. These variables can significantly affect how the battery is drained and should be taken into account when estimating battery life.

By iteratively calculating battery life based on power consumption profiles throughout the development project, developers gain valuable knowledge and intuition about the factors that affect the power profile. This understanding allows them to maintain the desired power profile despite changes in the development stack, ensuring optimal power usage and battery life.

Refined battery selection with battery profiling

Understanding the power consumption behavior of an IoT device goes beyond relying solely on data sheet information. It involves conducting a critical analysis to assess the battery's performance in the unique scenario relevant to your project. This process provides insights into the battery's efficiency, stability, and suitability for the deployment.

Defining a Battery Profile

A battery profile is not just a general overview; it is a tailored description of how a battery discharges under specific loads in particular environments. You can find such profiles in the battery's data sheets. To select the ideal battery for your solution, you need to create profiles that align with your device's power requirements. Additionally, it is beneficial to profile several battery alternatives from different brands, batches, and temperatures to gain a thorough understanding of their behavior.

By following these steps, you can gain a deeper understanding of the power consumption behavior of your IoT device and make informed decisions when selecting the most appropriate battery for your project.

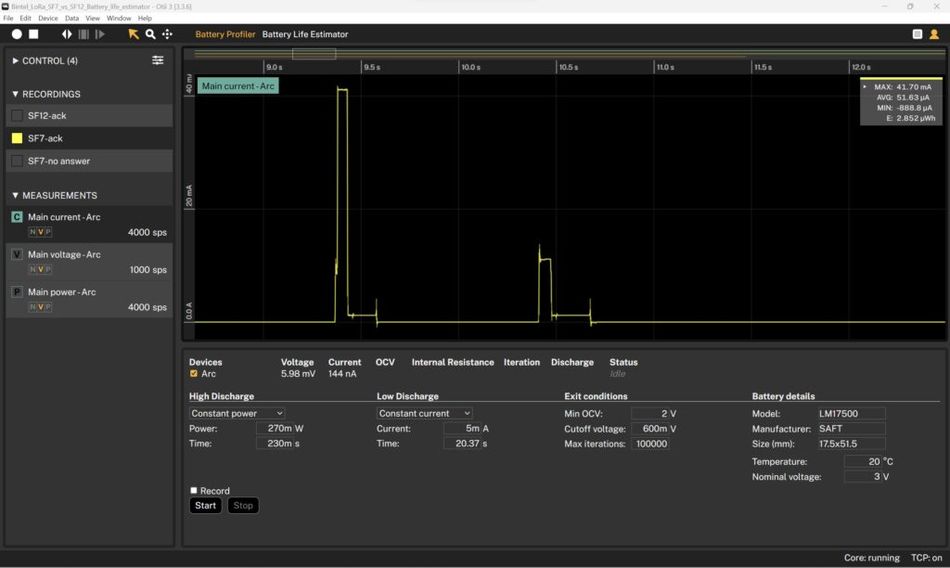

Accelerated Battery Profile

To create a battery discharge profile that aligns with your device's current consumption profile, you may need several months or even years. Thus, it is essential to develop an accelerated discharge profile. Here are some best practices to create an accurate and helpful profile:

Maintain High Discharge Consistency: Coin cell batteries are particularly sensitive to high discharge, so it is crucial to match your device's peak current. Lithium-ion rechargeable batteries can withstand higher discharge currents, while alkaline batteries fall in between.

Shorten Cycle Time: Determine the low discharge time the battery requires to recover.

Increase Sleep Current: Ensure the battery can recover even in high discharge. Consult with Manufacturers: Seek assistance from battery manufacturers to verify your assumptions for the batteries you want to profile.

Accuracy Considerations

It's worth noting that precisely matching the discharged energy in the accelerated profile to the original profile may not be feasible, which could affect the profile's accuracy. The less acceleration used, the more accurate the results, but this method's level of accuracy is usually adequate for IoT implementations. It ensures a comprehensive real-world understanding of the battery's performance, contributing to successful IoT solutions.

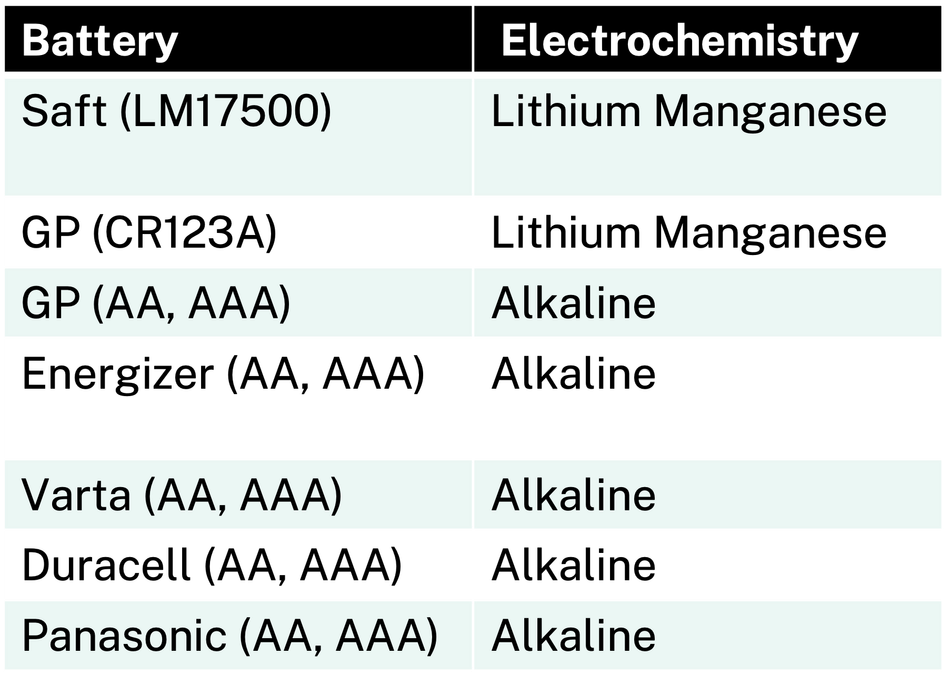

Profiling Different Battery Chemistries

Here is an example from a customer case with LoRaWAN waste management IoT device. For this specific application, we profiled two distinct electro-chemistries encompassing six brands, including multiple samples from each brand. The profiling was carried out at room temperature, using an accelerated battery profile developed with input from battery manufacturers. Comparing samples from multiple manufacturers allowed us to evaluate how different form factors and chemical compositions influenced the results. Profiling the batteries in various environments could be the next logical step to observe the available capacity deviation from these controlled profiles, given that the profiling occurred at room temperature.

Battery Profile Analysis

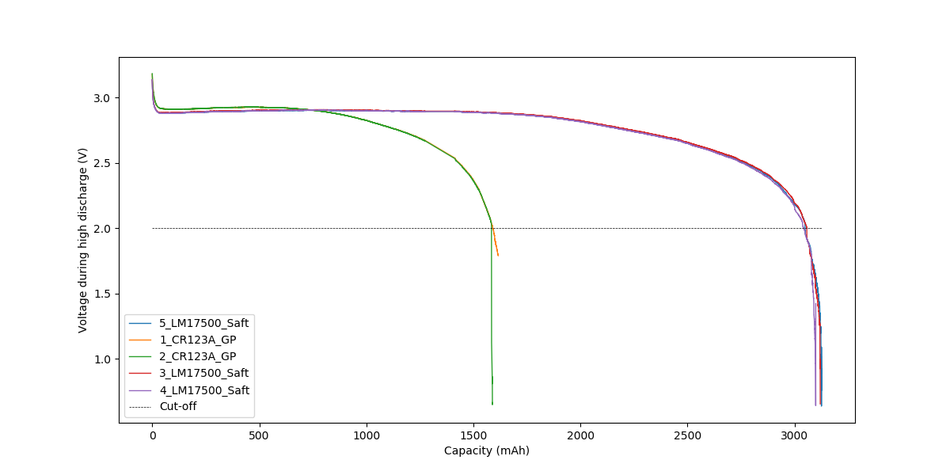

LM17500: Three samples of this battery were profiled, yielding an average capacity of approximately 3050 mAh before reaching the cut-off point, slightly higher than the data sheet capacity of 3000 mAh.

CR123A: Two batteries were profiled, with an average capacity of about 1600 mAh, consistent with the data sheet for that specific temperature.

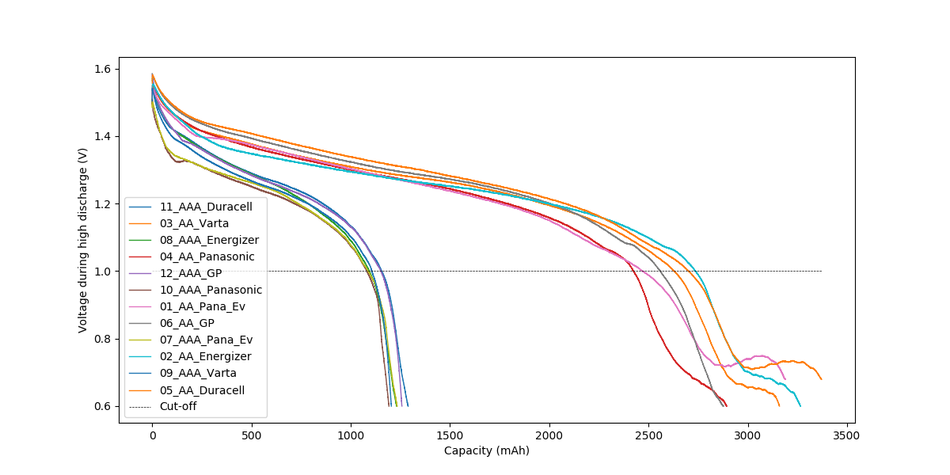

Interestingly, alkaline batteries exhibited significant variations in available capacity based on the manufacturer, which is a crucial consideration if customers will be responsible for battery replacement.

AAA: These batteries had capacities ranging from 1080 to 1150 mAh, with an average of around 1100 mAh. The data sheet indicated a capacity of 1200 mAh.

AA: The AA batteries showed a wider range of capacities, from 2420 to 2730 mAh, with an average of approximately 2590 mAh. For example, the data sheet for Varta indicated a capacity of 2950 mAh.

Our profiling process identified performance nuances across different battery brands, chemistries, and form factors. These insights are crucial for making informed decisions specific to the device and use case, going beyond the data sheet capacities. Conducting profiling in diverse environmental conditions, particularly temperature, could further enhance our understanding and contribute to a more resilient IoT device design. You want to see more details from this study? Download the white paper.

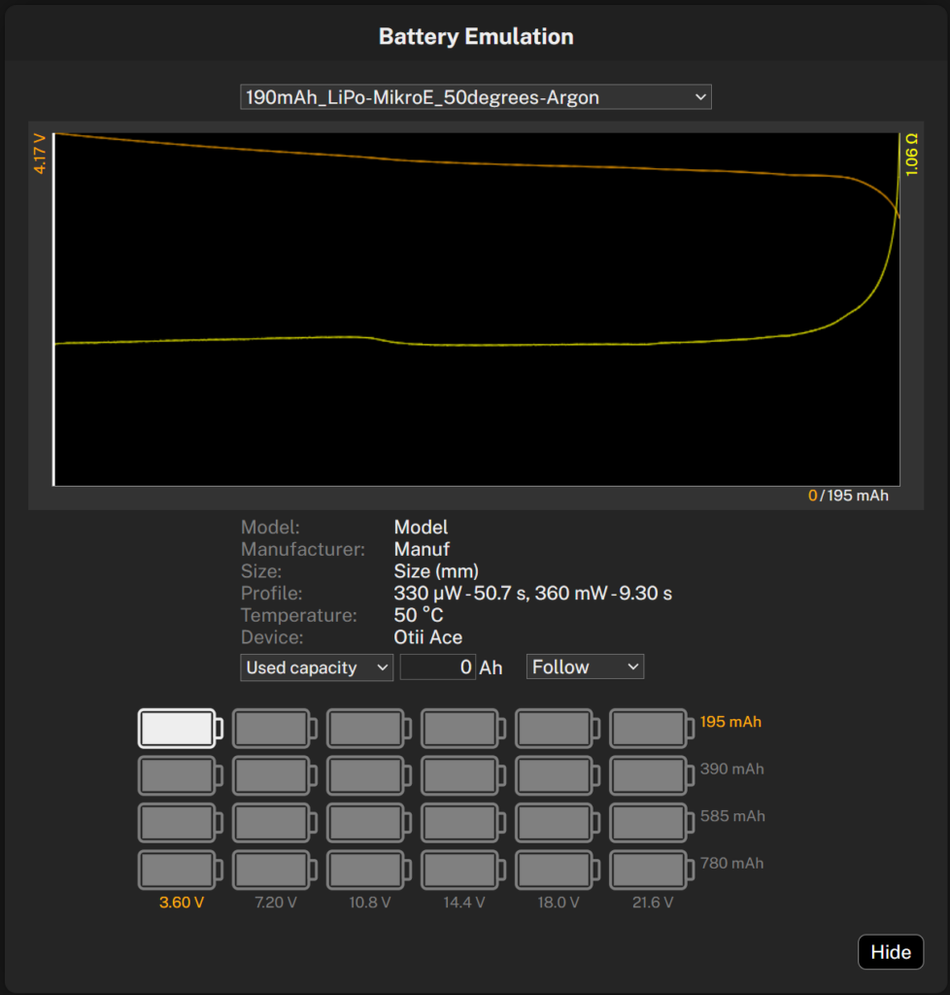

Replaying the Battery Profiles

Accurately measured battery profiles provide a more realistic and tailored understanding of the battery's capacity for a specific application, surpassing the information provided in mere data sheets when estimating battery life. By directly applying the profiled battery discharge to the device instead of using a standard power supply, you can determine the actual usable capacity and further enhance the accuracy of the estimation. The actual usable capacity depends on the behavior of the device itself, and in some cases, we have encountered as low as 20% of the measured capacity. Tools such as Otii Ace Pro with Battery Toolbox can replicate these battery profiles, effectively serving as profiled batteries for the IoT device. By adjusting the used capacity in the battery emulator of these instrumentsand monitoring when the device either shuts down or reboots, you can uncover the true, realistic usable capacity. This ensures a more precise understanding of the battery's potential in the context of the specific application.

Conclusion

We propose a technique for selecting the ideal battery: initial selection based on a defined use case and data sheet, power profiling of the IoT device and the battery for the use case, and a refined battery selection using device power behavior to assess the battery's real-world performance for the specific use case and device. This nuanced approach enables developers to make well-informed decisions that boost battery life.