How to Design Parts That can Be Easily Picked Up

During assembly, operators often complained that some parts are difficult to be picked up, either too small of too heavy. Consequently, assembly efficiency was lowered down. How can designers figure out a better idea so that operators can pick up the parts easily? Here are some advice as below.

1. Parts shall not be either too small or too heavy, too slippery or too viscious

Parts shall be of proper dimensions so that operators or robot arms can catch them and assemble them easily, not too small or too heavy. The easier the parts can be picked up, the smoother the assembly will be, the higher the efficiency will be. Or else, special auxiliary tools are needed to assist to pick up the parts, then the assembly efficiency will be lowered down increasingly.

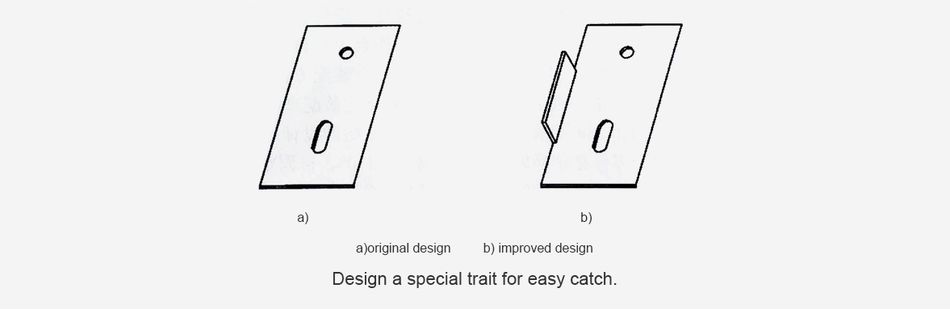

2. Design a special trait for easy catch

If the parts are very hard to be picked up due to their dimensions, then additional traits can be added on the parts while designing, like edgefold etc. In the graphic below, the parts are too thin to be caught and assembled in the original design. In the improved design, an edgefold was added so that the parts were much easier to be picked up and assembled.

3. Parts shall have no sharp edges or angles

Special attentions shall be paid to following issues. First, parts shall have no sharp edges or angles, or else, they may do harm to operators or consumers. Second, sharp edges or angles may damage the other products’ appearance or important parts. Thus, product designers shall change the sharp edges or angles to be rounded when they design parts.