Digitisation of Agriculture & the Underlying Technology Mandated

Widely publicised in the media, there are rising concerns both within the agricultural industry and from government policymakers as to whether food production can keep up with unprecedented future demands.

Image source: Ekobot

Widely publicized in the media, there are rising concerns both within the agricultural industry and from government policymakers as to whether food production can keep up with unprecedented future demands. The ever-expanding population (especially in developing countries), combined with limited suitable land reserves and workforce issues, plus numerous different environmental factors, means that there is a serious risk of food supply shortages becoming increasingly commonplace.

It is now widely acknowledged that technology will need to play a pivotal role in next-generation agricultural activities, helping to transition from less efficient traditional methods and any remaining reliance on manual work. Such technology will enable the crop yields per hectare of land to be significantly increased, and make better use of essential resources, while also keeping labour costs down.

Boosting worldwide food production

Based on United Nations’ figures, it has been extrapolated that the global population will grow from its current total of 7.9 billion to over 10 billion within the next 35 years. Consequently, there will be at least another 2 billion people to feed on top of what we have today (and attending the current population is already proving to be challenging enough). Combating climate change and protecting biodiversity means that making more land available through deforestation is simply not acceptable. Ways must therefore be found to make better use of existing farmland.

Critical to the adoption of smart agricultural practices will be the acquisition and subsequent analysis of data. Sensor devices will be deployed across farming sites, in order to provide continuous updates on key parameters affecting food production (such as air temperature, humidity, degrees of illumination, etc.). This will mean that farmers are able to gain the information they need to respond to changing circumstances - whether that is short-term fluctuations in growing conditions or the uncovering of trends which will need a longer-term solution.

Irrigation and fertiliser use both represent major operational expenses for farmers. Likewise, powering the lighting needed for vertical farms and indoor horticultural sites will be among their largest yearly financial outlays. Making certain that these aspects are being optimally utilised is thus paramount - and that is why advanced sensor implementation is going to be needed.

Fundamental sensor attributes

The sensors used in an agricultural context need to have certain characteristics if they are to be effective in their assigned function. Firstly, they must be robust enough to cope with the application environment in which they are situated (so that continued operation can be relied upon). Secondly, they need to deliver accurate data - otherwise the decisions made by farmers based on this data may be incorrect, with crop production volumes or crop quality suffering as a result. Finally, these sensors have to be accompanied by appropriate connectivity.

Soil measurements

One of the many different areas of agriculture where having constantly updated parametric data will be of real value is in relation to soil. This will allow farmers to gauge what amount of nutrients and salt ions are present, and check for sufficient rainfall. They will be able to gain insight as to whether they are using the right quantities of fertiliser, or if the irrigation system in place is working satisfactorily, as well as looking for signs of groundwater pollution.

The distribution of soil sensors will depend on the nature of the crop being grown, and how closely parameters need to be monitored. For higher value crops (such as the grapes used in winemaking), greater sensor density will be justified. How regularly data needs to be acquired will also be crop dependent, as well as the actual methods being used. For outdoor farming operations, updates every 30mins are likely to be adequate, but for indoor set-ups this might go down to as often as every 5mins.

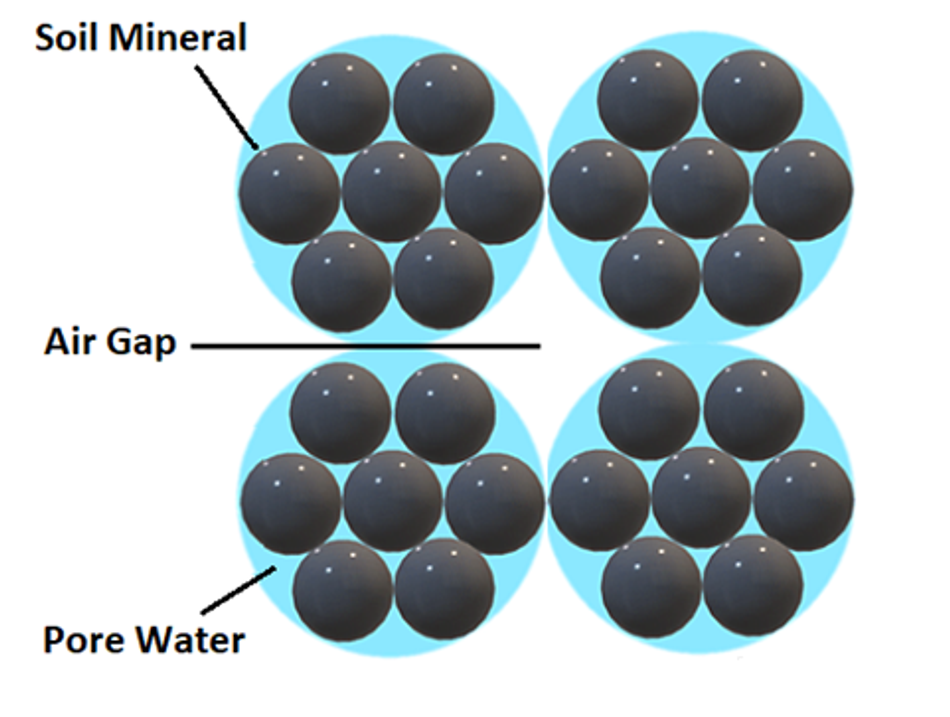

As shown in Figure 1, soil samples will basically consist of the soil mineral itself (in the form of grains), air gaps and pore water. The nutrients within the soil, along with the fertiliser chemicals, will be carried in the pore water. In-depth studying of soil conditions will require electrical conductivity (EC) measurements to be conducted. These will give data on the composition of the soil based on the resistance properties of each of its constituent parts.

One of the problems with existing soil sensor devices is that their accuracy can be detrimentally influenced by temperature variations and excessive water content, as well as the presence of chemical compounds. Another problem that needs to be factored in is that rocks between the sensor’s electrodes can interfere with the results obtained. For this reason, a multi-electrode arrangement will prove to be much more accurate. The need to address these issues was what motivated Murata engineers to develop a new, more sophisticated soil sensor solution.

Through Murata’s soil sensor, it is possible for soil conditions to be continuously monitored. This highly-integrated device has three different sensing functions built into it, allowing different parameters to be examined simultaneously. These functions are:

- A nine-electro sensor element, via which EC can be determined.

- A moisture sensor element that measures electrical permittivity, so as to give a value for the volumetric water content (VWC) figure.

- A temperature sensor element.

The nine-electrode EC sensor is unique to the industry. This enables multiple measuring patterns to be generated, thereby eliminating uncertainty about the results derived. The moisture sensor covers a VWC range from 0 to 60% and maintains a full-scale moisture accuracy of ±3%. The temperature sensor supports a -20°C to 60°C temperature range with a ±1.0°C accuracy, and features a proprietary algorithm that compensates for temperature influences on the EC measurements. An additional proprietary algorithm has been incorporated into the device which means that exact figures on the fertiliser content can also be obtained (so signs of over-usage can be identified).

The Murata soil sensor device delivers elevated accuracy, while still being more cost-effective than competing solutions. It is housed in a robust IP68-rated enclosure, to safeguard against dust and liquid ingress. There is a choice of UART, RS232E, RS485-MODBUS and SDI-12 wireline interface options available, as well as support for wireless connectivity through a Bluetooth LE transceiver. The sensor’s data acquisition times are simple to adjust. With readings being taken at 30min intervals, three AA batteries will be able to power it for a period of at least 6 months before they need replacing.

Prior to releasing this solution, Murata undertook extensive testing in farming locations across Asia. Here it was successfully used to examine the salinity levels in rice fields, fertiliser usage in fruit orchards and irrigation efficiency at sites where peanuts were being grown.

Conclusion

A digital transformation of the agricultural sector must be initiated if the food supply chain is to be strengthened and shortage issues mitigated. Engineering innovations, like the three-in-one soil sensor just described, have the potential to make a substantial contribution to farming becoming more data-driven, leading to productivity being increased and running costs lowered.

About the sponsor: Murata

Murata is a global solution provider and the market leader in the design, manufacture, and supply of advanced, leading-edge electronic components, and multi-functional modules. Murata contributes to the advancement of society and the electronics industry, in close cooperation with its customers and other stakeholders. Their European HQ is based in the Netherlands.

If you have any questions based on this article that you would like to discuss with an expert at Murata, don't hesitate to reach out. There's an entire team ready to support you with your question.