Automated Quality Control Systems

More and more manufacturers are adopting automated quality control systems in order to detect issues before it is too late or to reduce quality control costs.

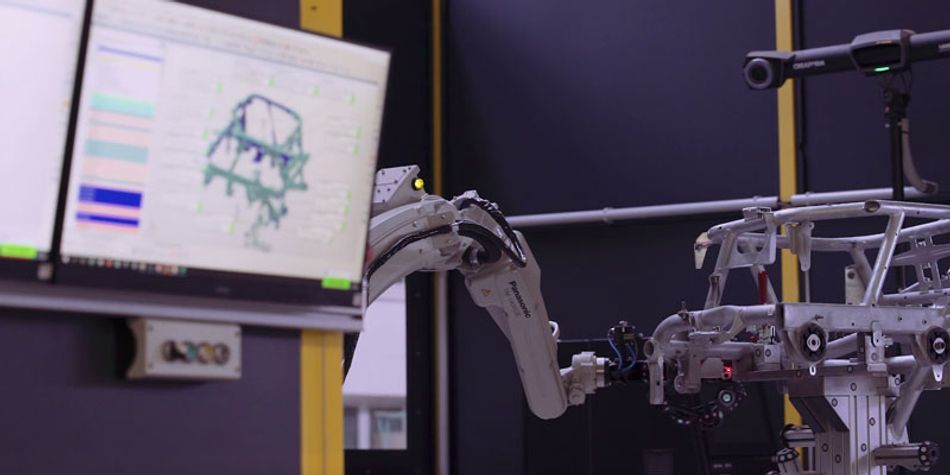

Credit: Walter Automobiltechnick: Automated quality control of a motorcycle frame

Why are automated quality control systems important for today’s manufacturers?

More and more manufacturers are adopting automated quality control systems in order to detect issues before it is too late or to reduce quality control costs. Automated quality control systems also enhance overall product quality, increase throughput, mitigate obsolete and cumbersome manual inspections, and improve competitiveness.

Thanks to advances in various inspection and measurement technologies, automated quality inspection systems, particularly inline and at-line metrology solutions, can be implemented quickly to address a manufacturer’s many quality control issues.

Let’s look more closely at automated quality control systems and how they are transforming manufacturers’ industrial processes.

What is the difference between manual inspections versus automated inspections?

The processes of manual quality inspections versus automated quality inspections are vastly different.

What are manual quality control inspections?

With completely manual inspections, technicians and operators measure, inspect and assess products, either throughout the production line or at certain intervals during production runs. Completely manual interventions rely solely on human observation and no inspection devices or technology.

Other manufacturers conduct first-article inspections (FAIs) in a dedicated metrology lab with coordinate measurement machines (CMMs). These types of inspections may appear to be automated; in fact, they still require intervention by an experienced CMM specialist or metrologist to manually load, operate and unload the CMM.

However, these types of inspections are prone to human error and rely on the expertise of the technicians carrying out the work, which could negatively the accuracy and reliability of inspection measurements. Moreover, manual inspections can cause major bottlenecks, depending on inspectors’ efficiency as well as availability of the lab and CMM. Finally, inspectors cannot possibly inspect every single part or product in a high-throughput environment. The end result? Decreased output and compromised production timelines.

What are automated quality control inspections?

Automated inspections virtually eliminate all the cons associated with completely manual inspections and inspections conducted with a traditional CMM.

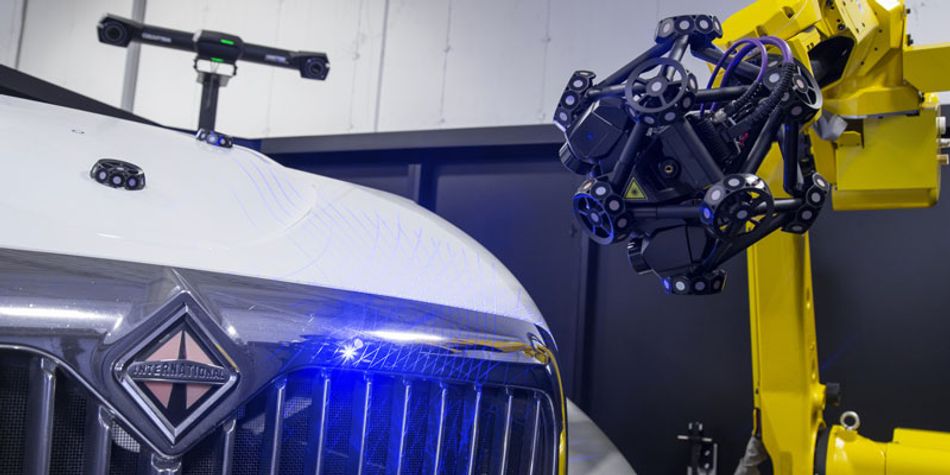

Oftentimes, manufacturers will choose a customized robot-mounted optical CMM 3D scanner or a turnkey 3D scanning coordinate measurement machine to optimize production cycles. They require no human involvement, except for loading and unloading, and enable automatic inspections at very high rates.

These automated quality inspection systems are used for many different applications, including inline and at-line FAIs, in-process inspections of parts and tooling, assessing supplier parts, and digitalizing quality control measurements for traceability and archiving.

How does automation improve quality?

Automated inspection systems offer many benefits that improve the quality of parts and complete products. Here are some examples of how automation improves quality:

- With a lack of experienced CMM operators, manufacturers are increasingly turning to automated quality control solutions to not only eliminate production bottlenecks but also improve the quality of the parts being inspected as automated systems are impervious to human error. Furthermore, qualified employees can be assigned to more added-value tasks, such as data and inspection analyses.

- Automated quality control improves inspection measurement reliability. Accurate measurements on complex parts and high throughput production lines is assured with automated inspections.

- These systems can capture more data for large quantities of parts faster. Combined with sophisticated reporting capabilities, manufacturers can make better decisions based on more reliable results from a higher number of components.

As automated quality control systems capture inexhaustible amounts of 3D data, a manufacturer’s quality control operations can provide dynamic, real-time reviews of production quality as well as comprehensive compliance tests to clients.

What are the business advantages of automated quality inspections?

The gains of automated quality inspections don’t just end with better quality products and parts. Manufacturers can also take advantage of their automated quality control process for:

Improved productivity

Manufacturers that conduct automated quality control inspections right on or very near the production line to optimize productivity. They can:

- Measure more parts per hour with the same number of dimensions

- Measure only the critical dimensions on a larger number of parts, increasing the number of parts measured per hour

- Measure the same number of parts, but get more information on each of these parts to build a history in order to present better traceability

- Measure more parts and more dimensions per hour

Defects and irregularities can therefore be detected more quickly, and corrective actions can be carried to preempt downtimes and respect production timelines.

Reduced staffing issues

Many manufacturers have difficulty in recruiting qualified, and experienced quality control staff; in a competitive market, metrology specialists and quality control inspectors are often hard to come by.

Automated quality control systems can be the solutions to labor shortages. The new generation of 3D scanning CMMs for automated quality control, which are extremely intuitive and easy to use, can be operated by production personnel—with no expertise in robotics or metrology. Of course, members from the quality control department must be on hand to prepare inspection plans; nevertheless, production teams can use the automated quality control solution on a day-to-day basis.

It is important to note that an automated quality control system’s software integration also means that quality control technicians or engineers do not have to have any prior know-how with robotics. The latest generation of acquisition software and metrology software automatically calculate, simulate and execute robot paths from comprehensive inspection plans.

In sum, automated quality control systems, reduces recruitment, onboarding and training costs.

Decreased total quality control costs

Apart from associated labour costs and improved efficiency, automated quality control solutions can also decrease total quality control costs.

Did you know that quality-related issues can cost manufacturers up to 40% of sales revenue, according to the American Society for Quality? The costs most often incurred by lack of part or product compliance are severalfold:

- Rework and scrapping

- Production line downtimes

- Recalls and repairs

- Purchasing new materials

- Changes to the production planning to accommodate new runs

- Retesting

- Fees associated SLAs not being respected

- And much more

Indeed, automated quality control systems can significantly reduce the four major costs of quality (COQ): prevention, appraisal, internal failure and external failure.

Quality inspections using automated inspections can also increase business growth—and not just from the bottom-line gains from productivity and lowered COQ.

Better product quality also enables manufacturers to create more complex parts and products, which can lead them to address untapped commercial opportunities. Finally, better quality is a fairly reliable gauge that clients and end users end up purchasing from a manufacturer again.

How to choose the best automated quality control system?

To choose the right automated quality control solution for your organization, begin by mapping out your current inspection process and identifying major, most recurring problems of your workflow.

Take stock of the various automated quality control systems available based on your industry, needs, and components to be inspected. Research each systems pro’s and con’s based on reviews in specialized media. Don’t hesitate to reach out to various providers to ask for a demo and talk to automated quality control specialists about your challenges.

With just a little work, you are sure to find the right automated quality control solution for your next production run!