Advanced Adhesives for Electric Motor Assembly: Driving Performance and Reliability

Engineered adhesives are essential enablers of performance, durability, and manufacturability in electric motor assembly.

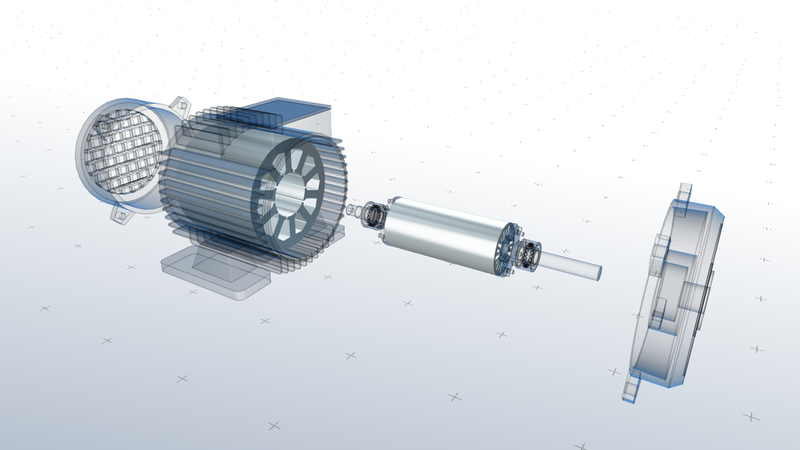

Traditional mechanical fasteners have long been the default in motor assembly. But as electric motors (e-motors) evolve across mobility, consumer goods, and industrial automation, these fasteners are becoming a limiting factor. Today’s motors must be stronger, lighter, and more compact, pushing engineers to rethink how they are built. Advanced adhesives are enabling that shift.

Once seen as alternatives to bolts and clips, today’s engineered adhesives are essential enablers of performance, durability, and manufacturability. Kisling, a specialist in industrial adhesives, offers a portfolio of solutions tailored for the evolving demands of e-motor assembly.

Why Adhesives Are Critical for Electric Motors

Electric motors operate under high stresses and tight design constraints. Traditional mechanical fasteners add weight, limit design flexibility, and concentrate stress at specific points, which are challenges that adhesives help overcome. The compatibility of advanced adhesive technologies across different materials, flexibility, and ease of use makes them highly adaptable to various applications that enable motor performance engineering.

Additionally, engineered bonding solutions have become increasingly valuable in e-motor manufacturing due to several instrumental advantages over traditional mechanical fasteners.

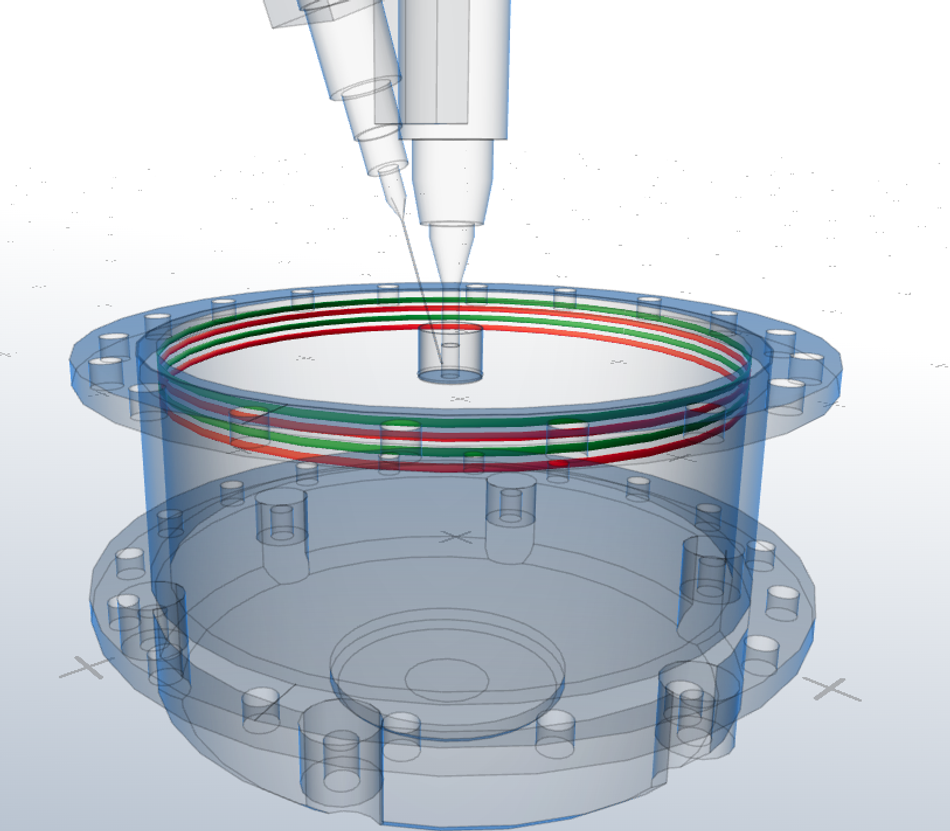

In stator potting, adhesives play a key role in thermal management and electrical insulation. Epoxy-based potting compounds with high thermal conductivity help dissipate heat from the windings while protecting against moisture, dust, and vibration. Their low-viscosity formulations allow deep penetration into coil windings, ensuring complete coverage and improved reliability.

Adhesives are also critical in permanent magnet motors for the secure fixation of magnets to the rotor or stator. These adhesives must withstand high centrifugal loads, temperature fluctuations, and chemical exposure. By eliminating mechanical joining methods, adhesive bonding allows for more compact designs and precise placement, improving motor efficiency and performance.

During rotor assembly, structural adhesives are used to join components such as shafts and laminations. These bonds must withstand constant rotational stress and high dynamic loads. Adhesives offer the advantage of uniform stress distribution and can bond various materials, reducing weight and simplifying assembly.

To protect internal motor components from environmental factors like moisture, dust, and oil, flexible sealants (mainly silicone-based) are used at the housing interfaces. These sealants accommodate thermal expansion and contraction while maintaining a secure seal, thus extending the motor’s operational lifespan and ensuring consistent performance.

Essential Properties of e-Motor Adhesives

E-motor adhesives must meet stringent performance requirements for durability, efficiency, and longevity. Key properties include:

Thermal conductivity and temperature resistance: Adhesives with high thermal conductivity (e.g., over 1.5 W/m·K, compared to conventional compounds in the range of 0.5–1.0 W/m·K) are essential for dissipating heat from components such as stators and rotors. Efficient thermal management enhances motor efficiency, extends service life, and prevents thermal degradation.

Chemical resistance: To maintain bond integrity, adhesives must resist exposure to chemicals, oils, and other automotive fluids.

Vibration and fatigue resistance: E-motors are subjected to constant vibrations, torque, and thermal cycling. Specific adhesives, such as urethane acrylate adhesives, exhibit excellent resistance to impact, peel forces, and vibrations, making them suitable for bonding metal sheets in stator or rotor assemblies.

Electrical insulation where needed: Providing effective electrical insulation is crucial to prevent short circuits and ensure safe operation. Some encapsulants offer both electrical insulation and flame-retardant properties.

Automation Compatibility: E-motor manufacturing requires repeatability and throughput. Adhesives must integrate seamlessly with automated dispensing and curing systems, supporting process efficiency and scalability.

Kisling’s e-Motor Adhesive Solutions

Kisling’s portfolio of tailored adhesive solutions addresses the specific needs of e-motor manufacturing. These products balance high technical performance with sustainability and efficiency.

Stator potting compounds

Kisling’s polyurethane encapsulants, like the 8503+8901 system, are engineered for high thermal conductivity (1.5 W/m·K), facilitating efficient heat dissipation in compact motor designs. When applied using vacuum potting processes, it enables thorough impregnation of windings, enhancing insulation and protecting against moisture and mechanical stress. These compounds also comply with REACH and RoHS directives, contributing to safer and more sustainable manufacturing processes.

Magnet Bonding Adhesives

For securing magnets within rotors or stators, Kisling’s anaerobic adhesives, such as product 4451, offer high static shear strength and rapid curing times (fixture time of 2-5 minutes). These adhesives are designed to withstand centrifugal forces and thermal cycling, ensuring reliable performance in demanding e-motor applications.

Rotor Assembly Solutions

In rotor assembly, structural adhesives provide robust bonding of components like shafts, laminations, and mixed-material assemblies. Kisling’s high-strength anaerobic adhesives facilitate uniform stress distribution and can bond different materials, reducing weight and simplifying assembly processes.

Housing Sealing Materials

Kisling adhesive solutions are designed with automation compatibility in mind, supporting precise application and scalability for high-volume production lines. The company also prioritizes environmentally responsible formulations: many are solvent-free and developed without substances like isocyanates and halogens.

Applying Advanced Adhesives in Practice

Consider a motor manufacturer producing compact industrial stators for high-efficiency applications. The engineering team is tasked with selecting a potting compound that meets a strict set of requirements:

Good flow properties to fill narrow spaces between copper windings

Self-leveling behavior to minimize air pockets and ensure complete coverage

Thermal conductivity ≥ 1.0 W/m·K to support effective heat dissipation

REACH compliance for safe, sustainable production

Compatibility with automated processes and scalable curing workflows

In this scenario, a two-component epoxy system like Kisling’s 8503+8901 is well suited to the job. With a mixed viscosity of approximately 8,500–12,500 mPa·s at room temperature, it is designed for vacuum potting processes that enable thorough winding impregnation. The material is thermally conductive (1.5 W/m·K), solvent-free, and REACH compliant, meeting both performance and regulatory requirements.

While it cures at room temperature, the system supports scalable production through standard dispensing setups and extended pot life, making it adaptable to mid- and high-volume manufacturing environments. engineering teams balancing electrical insulation, thermal management, and production efficiency, this type of adhesive offers a consolidated, workflow-friendly solution.

Conclusion

Adhesive technologies are the driving force that defines the boundaries of performance, efficiency, and compactness in e-motor designs. Kisling’s advanced e-motor adhesives not only meet the technical demands of today’s applications but also anticipate the sustainability and automation needs of tomorrow. This makes them a trusted partner for high-performance electric motor assembly.

To learn more about Kisling’s e-motor adhesives, submit an enquiry via this short form.