Additive Manufacturing in Mechanical and Plant Engineering: Experience Drives Innovation

Discover how additive manufacturing revolutionizes mechanical and plant engineering, enabling lightweight designs, smart materials, and efficient production. Explore the innovations and collaborations shaping the future at Formnext 2025.

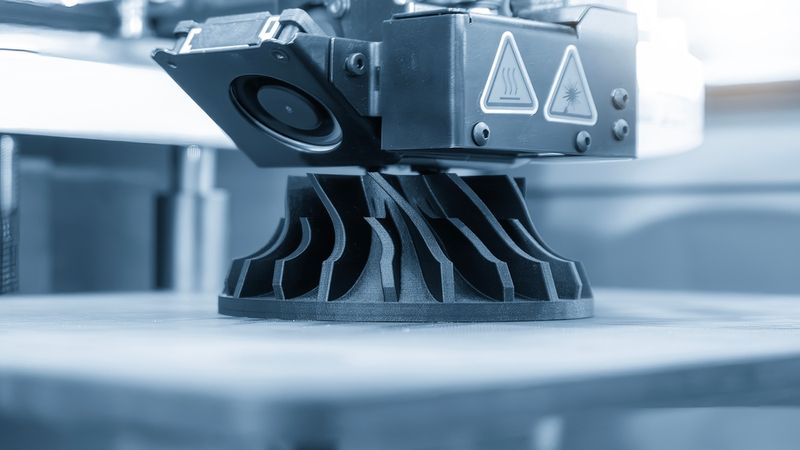

Additive Manufacturing by 3D Printer Machine

Additive Manufacturing (AM) has evolved from a niche prototyping tool into a cornerstone of industrial innovation, particularly in mechanical and plant engineering. Once limited to experimental design, AM now underpins complex, high-performance systems that define the next generation of manufacturing.

Markus Heering, Managing Director of the VDMA AM Working Group, emphasized that the success of Additive Manufacturing relies on close collaboration and shared expertise between technology providers and industrial users [1]. This collaboration fosters knowledge exchange, enabling industries to move beyond traditional constraints. Formnext 2025 in Frankfurt stands as the global hub where these collaborations flourish, uniting the latest advancements in AM materials, machinery, and applied solutions [1].

Visitors can learn more about the upcoming event and take advantage of various opportunities on the official Formnext 2025 visitor information page.

Why Additive Manufacturing is a Game-Changer in Machinery Design

Additive Manufacturing has fundamentally transformed how mechanical components are designed and produced. It enables engineers to integrate multiple functions into a single, optimized part, something that conventional manufacturing often struggles to achieve due to tooling limits and assembly complexity.

In traditional processes, intricate geometries increase both time and cost. In Additive Manufacturing, however, “complexity is free.” Whether a design involves detailed internal structures or unconventional shapes, the production cost remains largely unaffected. This principle gives engineers greater creative freedom to produce lighter, more compact, and more efficient components than ever before [1].

Unlike injection molding, which relies on standardization and constrains individualization, AM allows each component to be created as a unique entity tailored to specific performance requirements. Rather than replacing established manufacturing techniques, it enhances them by bringing flexibility, customization, and speed that redefine what is possible in modern machinery design [1].

The Manufacturing Spectrum: From Custom Machines to Mass Production

Mechanical engineering encompasses an extensive range, from bespoke, one-off systems to mass-produced industrial machinery. AM thrives within this diversity by accelerating concept-to-part cycles and offering cost-effective prototyping with unmatched reliability.

For example, a packaging-line component redesigned with AM can drastically shorten production lead times and optimize system throughput. This capability allows manufacturers to respond quickly to market demands while maintaining quality and functionality [1].

Choosing the Right Printing Process

Selecting the optimal Additive Manufacturing (AM) process is central to achieving a balance between performance, cost, and production efficiency. Broadly, AM technologies can be grouped into three primary categories based on their functional focus and application range [1].

1. High-detail processes (SLA, DLP):

These methods excel in producing intricate, high-precision components where surface quality and visual detail are critical, though they are generally less suitable for heavy mechanical loads.

2. Functional material processes (FDM, SLM):

Designed for strength and reliability, these techniques are ideal for manufacturing load-bearing or high-performance mechanical parts.

3. Polymer/Metal printing technologies (Binder Jetting, Sand Printing):

Used for specialized and industrial-scale applications, these processes enable the production of complex tooling, molds, or large-format structures. Unlike the previous methods, they focus on material versatility and scalability, enabling the creation of parts in both polymers and metals that cannot be realized through conventional methods.

Each process has its own “sweet spot,” where the interplay of material choice, design requirements, and intended function determines the most efficient and cost-effective outcome. Selecting the right technology for a given purpose remains one of the most decisive factors in achieving successful AM integration across mechanical and plant engineering [1].

Smart Materials: From Digital Customization to Real-World Performance

AM materials have advanced to mirror the mechanical and thermal properties of series-identical parts, whether polymer or metal. However, anisotropy —the directional dependence of strength due to print orientation —remains a consideration in component design.

Innovations such as multi-material printing and gradient structures now enable the fabrication of components with tailored stiffness and damping characteristics. For instance, vibration dampers produced through material jetting can gradually transition from rigid to flexible zones, improving durability compared to traditionally bonded metal-rubber assemblies. Similarly, lattice architectures allow optimization of rigidity and flexibility, providing unprecedented control over mechanical behavior. These developments redefine mechanical performance, turning material design into a digital engineering discipline [1].

AM in Action: From Prototypes to Production

Individual Parts and Small Series

Additive Manufacturing remains indispensable in rapid prototyping and limited-run production. MIKROMAT’s integration of 3D-printed sand cores into its casting processes exemplifies hybrid innovation—combining AM’s precision with conventional milling to achieve large, complex molds up to 80 tons [1].

As Ralf Wagner, Head of MIKROMAT Rapid Technologies, explains, 3D printing serves as a tool for swiftly and safely creating prototypes and, when necessary, small production runs. This adaptability allows manufacturers to move seamlessly from concept validation to pre-series production with minimal disruption [1].

Series Production and Process Optimization

In serial production, AM’s value lies in performance optimization rather than cost parity. TRUMPF’s 3D-printed water distributor demonstrates this principle: despite being 62% more expensive per unit, it achieved an 8.5× improvement in operational efficiency by optimizing internal cooling channels [1].

The case illustrates AM’s indirect economic benefits—reduced assembly complexity, fewer components, and streamlined logistics. As Arne Steck of TRUMPF explains, such integration eliminates multiple drawings, ERP entries, and spare part inventories, leading to cumulative cost savings that far exceed initial expenses [1].

Challenges and Lessons Learned

Despite its promise, AM faces several industrial challenges. Productivity limitations in Laser Powder Bed Fusion, along with residual stress and porosity issues in metals, continue to hinder scalability [1].

Moreover, the high cost of certified materials and equipment restricts adoption. Wladislaw Mischura of Krause DiMaTec explained that many failures arise when engineers attempt to print parts originally designed for machining—a reminder that effective design for additive manufacturing requires its own expertise [1]. Overcoming these barriers requires expert consultation, training, and collaboration to align design thinking with AM’s unique capabilities.

Expert Tips for Successful AM Integration

Practical success in Additive Manufacturing requires not only technical precision but also strategic awareness across every stage of production. The five core principles guide effective implementation within modern mechanical and plant engineering [1].

1. Print “Good Enough,” Not Perfect:

Overengineering can extend build times and inflate costs without yielding significant performance benefits. Striking the right balance between quality and efficiency is essential.

2. Minimize Post-Processing:

Intelligent part orientation and the use of advanced techniques, such as dry ice blasting systems like Toolcraft’s SupportBlaster 320-HA, can dramatically reduce post-processing effort and expense.

3. Choose the Right Metal Printing Technologies:

Selecting materials that align with functional goals, such as polymers for tooling and metals for structural components, ensures both reliability and value.

4. Build Internal Expertise:

Investing in design and engineering training equips teams to understand process capabilities, optimize designs, and make informed technology choices.

5. Leverage Consulting and Automation:

Collaborative work with a research institution like Fraunhofer IPK demonstrates how robot-assisted finishing can industrialize AM safely and efficiently.

Together, these principles demonstrate that long-term success in Additive Manufacturing depends on integrating technology, expertise, and disciplined process control.

Establishing AM in the Industrial Ecosystem

Additive Manufacturing has matured into a permanent fixture of industrial production. TRUMPF’s Arne Steck advises companies to remain actively engaged with additive technologies, continuously optimize their processes, and consider the entire manufacturing chain to achieve sustained performance improvements. Efficient, smaller systems often outperform larger idle ones, proving that scalability in AM depends on utilization, not machine size [1].

For many enterprises, AM now bridges the gap between prototyping and mass production—transforming from an experimental tool into a strategic production technology.

Formnext 2025: The Convergence of Knowledge and Opportunity

Formnext Frankfurt 2025 stands as the definitive platform for engineers, manufacturers, and innovators to exchange expertise, experience live demonstrations, and explore the latest advances in Additive Manufacturing. The exhibition’s combination of theory and practice fosters a culture of applied learning, enabling professionals to translate ideas into tangible industrial solutions.

The future of mechanical and plant engineering rests on the integration of know-how, collaboration, and experience. Success in this field is determined by the ability to connect technological innovation with practical understanding. Those driving the evolution of mechanical and plant engineering can experience these breakthroughs firsthand at Formnext 2025, where the future of industrial manufacturing takes center stage.

References:

Formnext AM in Mechanical and Plant Engineering: Know-How and Experience Determine Success. Stuttgart, Germany: Mesago Messe Frankfurt GmbH (white paper)