A microfluidic chip monitors gases using integrated, motionless pumps

The integrated design achieves accurate micro gas chromatography and can help reduce the cost of monitoring chemical synthesis, natural gas pipelines or at-home air quality.

This article was first published on

news.engin.umich.eduA new microscale gas chromatography system integrates all fluidic components into a single chip for the first time. The design leverages three Knudsen pumps that move gas molecules using heat differentials to eliminate the need for valves, according to the University of Michigan Engineering study published in Nature Microsystems & Nanoengineering.

The monolithic gas sampling and analysis system, or monoGSA system for short, could offer reliable, low-cost monitoring for industrial chemical or pharmaceutical synthesis, natural gas pipelines, or even at-home air quality.

Miniaturizing gas chromatography

Gas chromatography has long been considered the gold standard for measuring and quantifying volatile organic compounds—gases emitted from industrial processes, fuels, household products and more. Recently, micro gas chromatography miniaturized the technology to briefcase-size or smaller, bringing gas analysis from the laboratory to the source.

Most micro gas chromatography systems use pumps and valves to move gas molecules from an input port to a preconcentrator, which extracts and concentrates samples, then from the preconcentrator to a column for chemical separation, and then to the detector and finally to an exhaust port. Up to this point, pumps and valves have been fabricated and assembled separately, which increases device size, assembly cost and risk of failure at connection points.

While a fully integrated, monolithic micro gas chromatography system was first envisioned in 2000, the design took 25 years to realize.

“It might sound like we just squeezed everything onto one chip, but there is much more to it than that. We had to redesign how the pumps work and overhaul our manufacturing process to manage complex thermal isolation challenges. We essentially turned the problem on its head to achieve this level of integration,” said Yogesh Gianchandani, a professor of electrical and computer engineering and mechanical engineering at U-M and co-corresponding author of the study.

The Knudsen pump solution

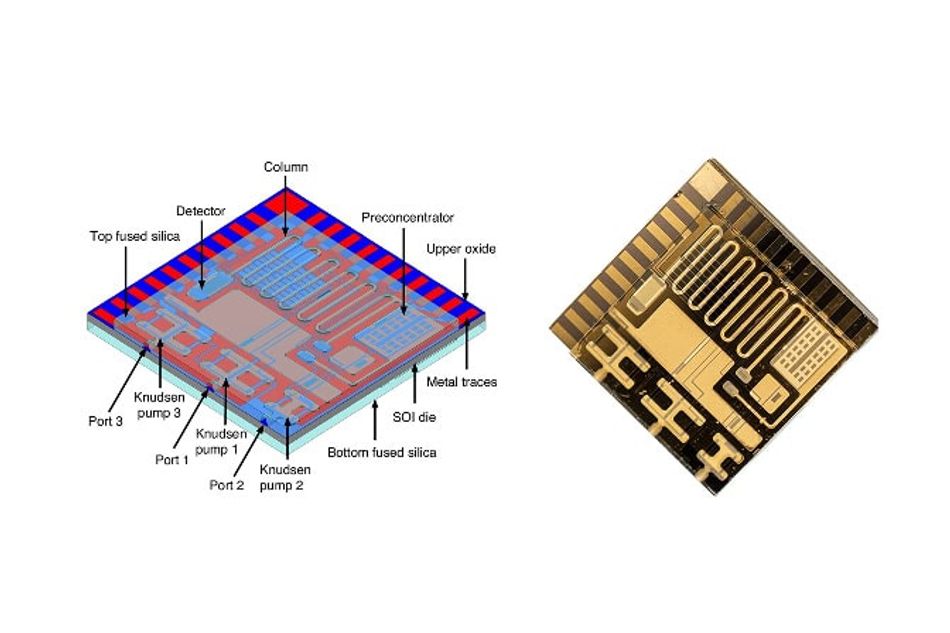

The 15-by-15 millimeter squared chip is made of a silicon-on-insulator (SOI) platform sandwiched between two layers of fused silica. Metal traces placed on top act as Joule heaters to create a hot side, while the thick silicon base creates a heat sink to maintain a cool side. Ultra-narrow channels, just 1.2 microns wide, create Knudsen pumps that move gas molecules from the cold side to the hot side without any moving parts.

“In channels this narrow, gas molecules have an increased chance of hitting the sidewalls instead of bumping into each other and creating random motion. As a result, thermal transpiration takes over, driving the molecules from the cold to the hot side,” said Yutao Qin, an associate research scientist of electrical and computer engineering at U-M and co-corresponding author of the study.

The monoGSA system leverages three Knudsen pumps to selectively direct gas flow. During the sampling phase, Knudsen Pump 1 (KP1) draws the gas sample into the preconcentrator, while KP3 provides counterbalancing pressure to prevent unwanted gas from entering the separation column too early. When it’s time for separation, KP3 pulls the gas from the preconcentration through the column and into the detector, while KP2 provides the counter pressure to prevent unwanted gas from leaking back in.

High accuracy with small volumes

The research team put the monoGSA system to the test against four distinct chemical mixtures that represent critical industrial chemical synthesis and environmental monitoring tasks. For each test, the monoGSA system sampled the air above a liquid mixture for two minutes, then allowed ten minutes for separation and detection.

The chip successfully quantified the chemicals within each mixture with an accuracy of ±6.5-8.5%. The system maintained performance in humidity levels from 15% to 100% and supported passive, low-power sampling modes, demonstrating suitability for long-term monitoring.

“What surprised me was how little gas flow we needed to achieve the results that we did. Most traditional systems require significantly more volume to get a clear reading,” said Gianchandani.

As a next step, the monoGSA system is ready to move out of the lab and into the field. The lower-cost, integrated design can help the chip reach both industrial partners and individual consumers for pollution or indoor air quality monitoring. In the long term, the research team envisions use in non-invasive medical diagnostic tools for breath analysis or even within wearable devices like a smartwatch.

The research was funded by the University of Michigan.

Prior to production in a commercial foundry, the device was prototyped in the Lurie Nanofabrication Facility, which is operated and maintained with support from indirect cost allocations in federal grants.

The team has applied for patent protection with the assistance of U-M Innovation Partnerships and is seeking partners to bring the technology to market.