6 features that enable industrial-grade 3D scanners tackle challenges of your projects in demanding settings

How will they help customers in their industrial applications? Photoneo’s Marcel Svec, Director of 3D Sensing, and Svorad Stolc, Head of R&D, have answered this and other questions.

The next generation PhoXi 3D Scanner

This article was first published on

www.photoneo.comStable performance in tough industrial conditions

The growing need for smart automation has caused that 3D vision, as an integral part of vision-guided robotics, has continuously been expanding into new markets. Gradually, the 3D vision has entered application areas such as robot guidance, bin picking, advanced object handling, depalletization, path correction, assembly, quality control, inspection, or shape evaluation.

These automation solutions often need to be implemented in challenging industrial environments that expose 3D vision systems to dust, humidity, water, ambient light, or high, low, and even varying temperatures. These factors pose demanding requirements on both hardware and the performance of 3D vision systems. The best 3D scanning devices need to be thoroughly optimized and provide micrometer accuracy and high resolution – yet they also need to withstand harsh industrial environments to keep their highest-quality performance in tough conditions. There are several aspects that affect the durability of modern 3D vision systems and help maintain their stable and accurate performance in challenging circumstances. What do they reside in?

Thermal stabilization

To extend the range of possible applications and ensure that a 3D scanner will provide stable and reliable performance not only in high or low temperatures but also under changing thermal conditions – which generally poses a big challenge to 3D vision systems – it needs to feature an advanced thermal calibration model. This feature will allow you to deploy your scanner in applications that require exposure of the device to truly demanding thermal conditions and its performance will remain unaffected.

Power over Ethernet

It is often the case that 3D scanning devices feature two different connectors – custom connectors providing power, and Ethernet or USB connectors enabling data communication. This setup is more expensive, more complicated with regard to installation, and it may also pose more limitations, for example on the cable length.

PoE – Power over Ethernet, is an elegant technical solution that provides both data and power over a single cable. It offers many benefits that make it a preferred choice for adoption in industrial settings. PoE is reliable, stable, and rugged. It is cost-effective in terms of both installation and maintenance, and also safe as it ensures over-current, under-current as well as fault protection. PoE provides great flexibility as it is standards-based, guaranteeing interoperability between different suppliers. Another advantage of PoE is that it enables users to use cables longer than 30 m.

Though PoE is the preferred option, we decided to support two standards to meet the needs of all customers – so users can power their devices also by 24 V. This alternative is also reliable and safe, operating with limiting circuits to protect against short circuits. Another advantage is that 24 V has higher ride-through capabilities, which helps the devices better survive voltage sags. In case of an accident, there is no risk of personal injury.

IP65: Dust-tight & water-resistant

High mechanical quality not only ensures that the device can reliably work in challenging conditions without suffering any damage but it also minimizes the risk of unnecessary service and related repair costs. The universal IP rating system provides buyers and users a very exact account of how safe it is to use a device in specific environments and applications. The IP rating consists of two digits. The first digit indicates how much solid intrusion the product can handle, and the second digit indicates the degree of tolerance to water.

Industrial-grade 3D scanners should aim for a minimum of IP65. Scanners with this rating are completely dust-tight and protected against low-pressure, 6.3 mm jets of water coming from any direction and at any angle. You can thus use the scanners in dusty or humid halls, not needing to worry about solid particles and liquids getting into the housing and damaging the device. Still though, while such environments will not harm the device, they are generally not optimal if you need to achieve high quality and low noise scans as they significantly affect the optical conditions of the acquisition.

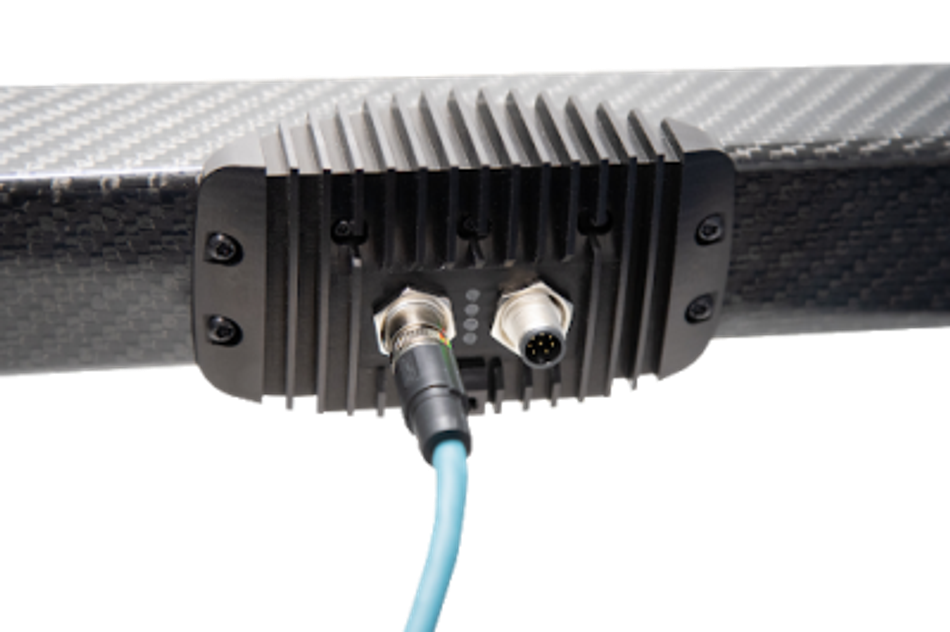

M12 connectors

M12 connectors have become the preferred choice for industrial applications for several reasons. Connectors with screw-on locks provide reliable and safe connection, and their circular design ensures unbeatable ruggedness that protects the device from dust, moisture, and other contaminants, but also against the potential effects of impact, vibration, or temperature changes. A big plus is also their compact size with respect to the increasing need in industrial applications for the miniaturization of components and the ever-growing demands for power and data transmission.

Fast GPU

Time is a critical factor in 3D scanning, therefore we made significant improvements in this respect too. Utilizing the power of NVIDIA Jetson TX2, the new generation of PhoXi 3D Scanner enables users to save 40% of the computation time, which makes 200 ms of the overall scanning time. This can shorten the cycle time or, in case of a longer acquisition, it provides data of greater quality and in a shorter time than before. Another advantage of using a GPU is that the computation runs on the device, which saves PC resources, leaving space for more user applications.

Powerful firmware

Because software and firmware are inextricable components of any 3D vision system, it was important to make upgrades in these areas as well. Alongside general improvements, the firmware now offers more user settings for better control of the whole scanning process. It also comes with upgraded algorithms for ambient light suppression, thanks to which the 3D scanners deliver superior performance even in bright ambient light settings – a factor that generally poses major challenges to 3D vision systems.

Another big upgrade relates to reflection filtering – the new, intelligent algorithms remove artifacts that occur in areas of complex scene geometries where the reflection of projected patterns causes noise and incorrect measurements. This happens with any type of scanning device that uses its own illumination method. Thanks to the new reflection filter, the 3D scanners significantly eliminate wrong measurements.