5 Design Tips to Cut the Cost When Manufacturing Your Parts

The smallest design decisions can have a significant impact on the cost of your CNC machined parts. Do you know how to reduce the cost by a few adjustments to your part design? Please have a look at the 5 design tips which contain processing hole, manufacturing surface and parts depth.

Photo by Mastars on Unsplash

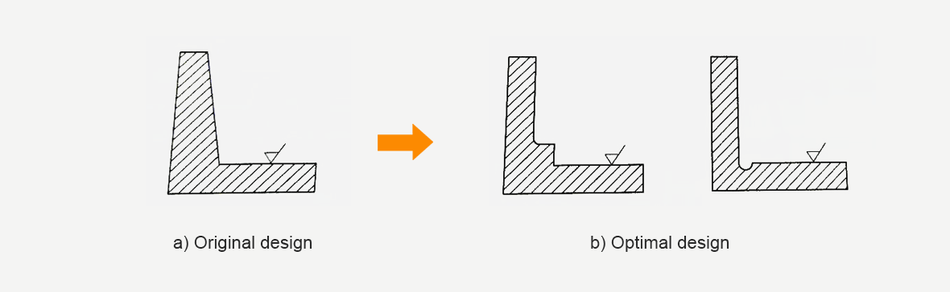

1. Adding a processing hole

Adding a processing hole to uniformize the wall thickness, and it can avoid deformation during heat treatment.

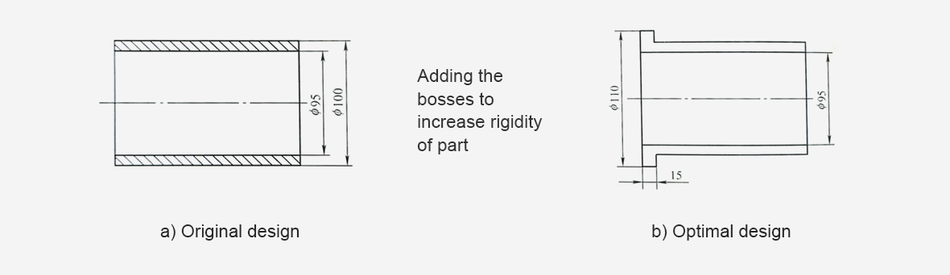

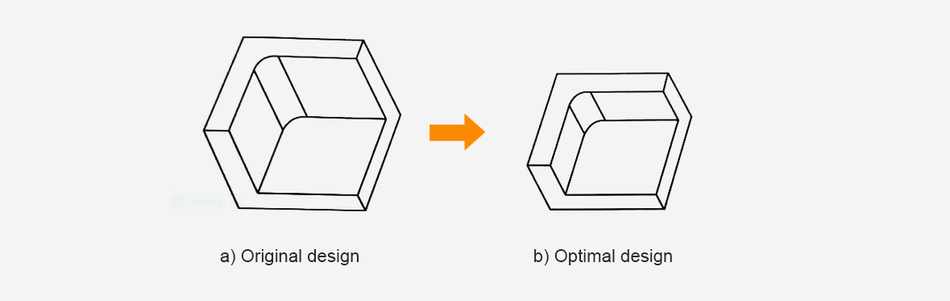

2. The structure of the part

In original design, the thin wall thickness is easily deformed by clamping force or cutting force. While in optimal design, the rigidity of part is increased after adding the bosses.

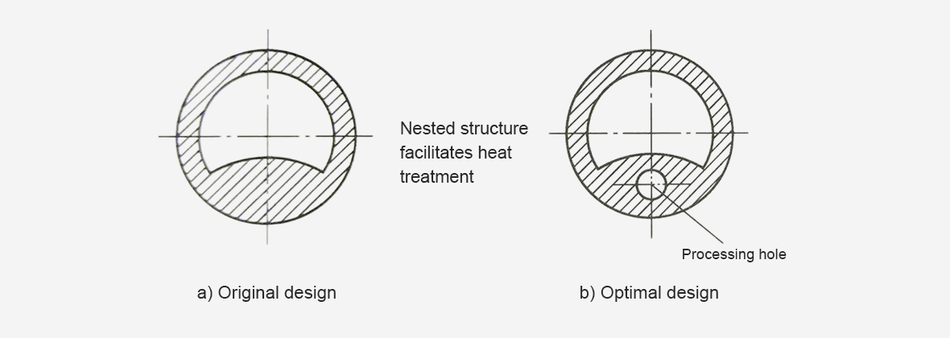

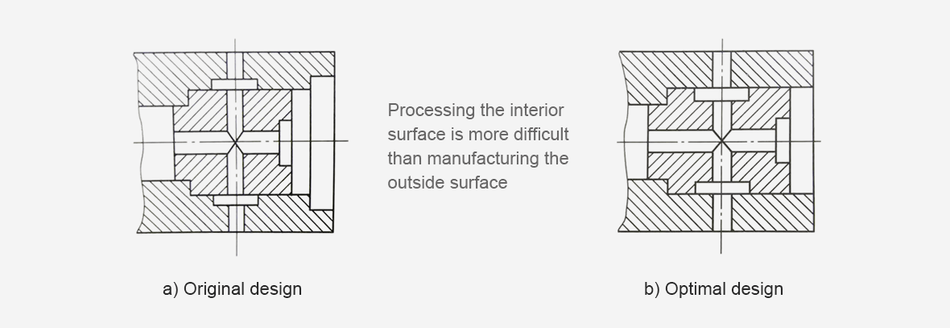

3. The outside surface

In original design, it's difficult to process an interior annular groove. While in optimal design, it’s easy to manufacture on the outside surface of the part, and does not impact the usage.

4. The machining area of milling

The machining area of milling should not be too deep, and the depth-to-width ratio should not exceed 3:1. Otherwise, the milling cutter is easy to break.

5. Long milling cutter

If a long milling cutter is unavoidable, the design can be optimized to improve the life of the milling cutter as the following pictures shows.