Ultimaker TPU 95A

A semi-flexible 3D printing material for fused filament fabrication that combines the properties of rubber and plastic materials suitable for industrial applications.

Technical Specifications

| Material | |

| Composition | Thermoplastic polyurethane |

| Colors | Black (RAL 9005), white (RAL 9010), blue (RAL 5002), red (RAL 3031) |

| Odor | Slight |

| Density | 1.22 |

| Water solubility | Insoluble |

| Solubility in other solvents | Tetrahydrofurane, dimethyl formamide, dimethyl acetamide, N-methyl pyrrolidone, dimethyl sulphoxide, pyridine |

| Filament | |

| Diameter | 2.90 ± 0.13 |

| Max roundness deviation | 0.07 |

| Net filament weight | 750 |

| Filament length | ~96 |

| Mechanical Properties | |

| Hardness Shore A | 96 |

| Hardness Shore D | 48 |

| Tensile modulus - XY | 67 ± 6 |

| Tensile modulus - Z | 56 ± 3 |

| Tensile stress at yield | No yield |

| Tensile stress at break - XY | 23.7 ± 2.1 |

| Tensile stress at break - Z | 6.4 ± 0.5 |

| Elongation at yield | No yield |

| Elongation at break - XY | > 560 |

| Elongation at break - Z | 82.3 ± 18.4 |

| Flexural modulus - XY | 62.6 ± 1.7 |

| Flexural modulus - Z | 62.6 ± 2.0 |

| Flexural strength - XY | 4.1 ± 0.0 MPa at 9.4% strain |

| Flexural strength - Z | 4.3 ± 0.1 MPa at 9.7% strain |

| Charpy impact strength (at 23°C) - XY | 36.0 ± 6.6 |

| Thermal Properties | |

| Melting temperature | 216.8 |

| Thermal decomposition | >230 |

| Auto-ignition temperature | >400 |

| Melt mass-flow rate (MFR) | 15.9 |

| Heat deflection (HDT) at 0.455 Mpa | 50.3 ± 1.1 |

| Vicat softening temperatrue | 115.7 ± 0.9 |

Overview

Desktop 3D printing has come a long way from its initial rapid prototyping purposes. The Fused filament fabrication (FFF) technology has been increasingly used for practical and functional applications by both home users and businesses. Still, the relatively reduced availability of materials and the final properties of 3D printed FFF parts can sometimes restrict the larger use of this technology by small and big companies alike.

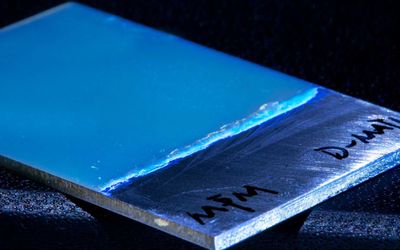

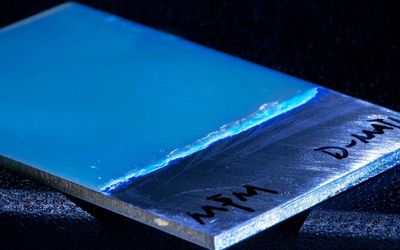

Ultimaker's TPU 95A filament is a thermoplastic polyurethane material with semi-flexible properties that helps expand the range of applications of desktop 3D printing. It combines the properties of rubber and plastic materials, offering elasticity with increased durability and impact resistance, plus electrical insulation and chemical resistance. This allows the 3D printed parts to benefit from the best functional properties of these materials while also ensuring more durable and reliable parts. While flexible and semi-flexible filaments are notoriously difficult to 3D print with FFF machines, Ultimaker claims its TPU 95A filament is both easier and faster to print than similar filaments in the market.

Design

The Ultimaker TPU 95A filament is 2.90 mm in diameter and comes packaged in spools containing 750 g of usable material. It is officially supported by the Ultimaker S5, Ultimaker S3, and Ultimaker 3 series, all of which when equipped with AA print cores, plus the Ultimaker 2+ series. The filament is available in four different colors: black, white, red, and blue.

Material properties

When printed in 100% infill, the material has a 96A hardness, which is comparable to semi-rigid plastics at the high end of the Shore A hardness scale. When 3D printed in this condition, the parts also display a rubber-like elasticity of up to 560% elongation at break, which is how much the material can be stretched about its initial form before breaking. However, these properties can be modified depending on the part's orientation, infill percentage, and wall thickness values used for 3D printing, which provides users with a high degree of customization.

The Ultimaker TPU 95A shows high impact strength and superior wear and tear resistance, being suitable for harsh environments and demanding applications. It also offers good corrosion resistance to most common industrial oils and chemicals.

Applications

Some applications include functional prototyping, industrial coatings, and end-use parts production such as grips, guides, hinges, sleeves, snap-fits, and cases. Some reported use cases by the industry include custom tooling by the automotive industry (Volkswagen Autoeuropa), in which the softer TPU prevents any damage to car parts, and also spare parts production for packaging machinery (Heineken).

The Ultimaker TPU 95A is not suitable for direct food contact applications, long-term UV and moisture exposure, and working temperatures higher than 116 °C.

3D printing information

Flexible and semi-flexible materials are prone to oozing during 3D printing and are challenging filaments to work with. While the Ultimaker TPU 95A is officially supported by Ultimaker 3D printers, any FFF 3D printer capable of processing 2.85 mm filament and meeting the temperature requirements could also 3D print it.

The Ultimaker Cura slicing software provides specific 3D printing profiles for the Ultimaker TPU 95A to ensure a proper printing process and strong layer adhesion. The recommended print settings for this material include a nozzle temperature of 220 - 235 °C and a build platform temperature of 70 °C.

The Ultimaker TPU 95A is not officially supported for dual-extrusion, although it can be experimentally printed with other Ultimaker filaments such as PVA, Breakaway, ABS, Nylon, and PC. The filament should be stored in a dry and cool ambient with temperatures ranging from -20 to +30 °C and relative humidity below 50%. Direct sunlight should be avoided.

Where to find it

UltiMaker

Since 2011, Ultimaker has built an open and easy-to-use solution of 3D printers, software, and materials that enable professional designers and engineers to...

References

Official product webpage

Material safety data sheet (SDS)

Material technical data sheet

Official 3D printing recommendations by the manufacturer

Applications and use cases for Ultimaker TPU 95A