Your Guide to 3D Printing BigRep PA12 CF

Today, BigRep’s large-format 3D printers are used for an incredibly broad range of applications, from large-scale models and prototypes to industrial end-use parts. It goes without saying that its range of 3D printer models are vital to this diversity, but the company’s materials, all optimized for large-format printing, also play a crucial role.

Today, the company has a well-rounded filament portfolio, comprising standard grades of PLA, ABS, and PETG, as well as engineering-grade materials like ASA, HI-TEMP CF and PA12 CF. In this article, we’re covering everything you need to know about PA12 CF, BigRep’s most heat resistant industrial filament.

What is PA12 CF 3D Printing Filament?

PA12 CF is a high-strength engineering-grade filament with excellent mechanical, thermal, and chemical properties. The material is primarily composed of Nylon 12 (PA12), a polymer with wide industrial applications (in packaging, food manufacturing, electronics, and more), and has 10% chopped carbon fiber reinforcement. These carbon fibers enhance the material’s stiffness, heat resistance, and durability creating even more applications for the 3D printing filament in industrial sectors.

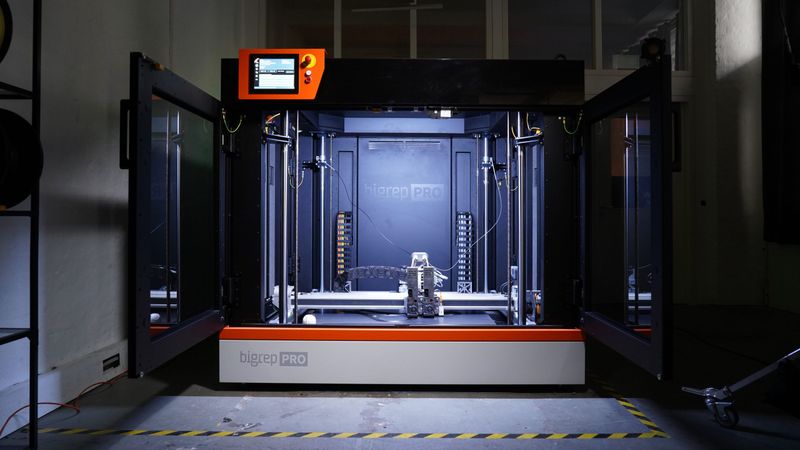

Like all of BigRep’s filaments, PA12 CF has been optimized for large-format 3D printing. This filament in particular is engineered for the BigRep PRO, but it can also be used with fused filament fabrication (FFF) systems with open materials and 2.85 mm diameter nozzles. The material’s primary properties, which we’ll dive into in more detail, are high strength and heat resistance, durability, stiffness, and excellent surface quality—right off the 3D printer.

Why Use BigRep PA12 CF Filament?

The combination of high strength and heat resistance make PA12 CF an excellent candidate for a range of functional applications. The BigRep 3D printing material is commonly used in the production of industrial tooling, such as molds, jigs and fixtures, as well as grippers and robotic end-of-arm attachments. This is because PA12 CF parts can withstand the stresses of an industrial manufacturing environment and be used reliably in combination with other machinery and industrial processes.

In addition to tooling, PA12 CF has end-use applications in various industries, such as automotive, electronics, engineering, and more. With a high heat deflection temperature of up to 130°C and long-term durability, the Nylon-based filament is also a popular option for metal replacement applications. Compared to printed metals, PA12CF is more affordable and more lightweight.

Benefits of 3D Printing BigRep PA12 CF

When it comes to 3D printing PA12 CF filament, one of the biggest benefits to users is that the large-format filament is easy to work with and requires minimal post processing. Right off the 3D printer, the material is characterized by a smooth surface finish, minimizing or even eliminating the need for additional chemical or mechanical post-processing. This has a huge benefit: you can save enormous time and resources by being able to use a printed component straight off the build platform.

In the printing process itself, PA12 CF also has certain advantages. For one, the carbon fibers embedded in the Nylon 12 matrix reduce warping on the print bed, which makes for a more reliable printing process and can even enable more complex part geometries. You can achieve the best print results by using a print bed adhesive, such as Magigoo PA glue or an additional print surface, like Kapton tape or BigRep SWITCHPLATE. Also important to making the most out of PA12 CF is following BigRep’s recommended print parameters:

Nozzle temperature: 270 - 300 °C

Print Bed Temperature: 40 - 60 °C

Fan speed: 0-30%

Chamber Temperature: n/a

Print Speed: 30-60 mm/s

What to Look Out For When 3D Printing BigRep PA12 CF

As with other carbon fiber reinforced filaments, it’s important to update your 3D printer hardware when working with PA12 CF. The fibers make for an abrasive filament that can quickly wear down printer nozzles made from brass. It’s therefore recommended to use a wear-resistant nozzle, such as a hardened steel nozzle, which can print PA12 CF without succumbing to rapid wear. Compared to BigRep’s other carbon fiber filament HI-TEMP CF, PA12 CF also has more demanding hardware requirements, particularly when it comes to nozzle temperature.

Carbon fiber reinforced filaments such as PA12 CF, while being stiffer than neat filaments, also tend to be more brittle. To account for this, you can orient parts strategically on the build platform to ensure that the part is strongest in the direction of stresses and loads. Finally, if you do plan to post-process PA12 CF parts, the material is compatible with a wide range of processes, including sanding, drilling, milling, as well as coatings like fillers, paints, and epoxies. When post-processing, be sure to wear suitable protection, like safety glasses, gloves, and a dust mask.

PA12 CF Material Properties

PA12 CF has exceptional material properties, making it one of BigRep’s most industrial-ready filaments. Let’s take a look at the filament’s mechanical, thermal, and chemical properties to better understand where its strengths lie.

Mechanical properties

PA12 CF is currently BigRep’s strongest 3D printing material, with a tensile strength of 71 MPa. For comparison, HI-TEMP CF has a tensile strength of 65 MPa, while ABS has a tensile strength of 30 MPa. This effectively means that parts made from PA12 CF can withstand greater stresses before breaking.

Thermal properties

If you are looking for a material that must be able to withstand high temperatures and retain its strength in demanding environments, PA12 CF is a good bet. The engineering-grade filament has an exceptional heat deflection temperature (HDT) of up to 130°C, higher than BigRep’s other high-temperature material HI-TEMP CF (115 °C). PA12 CF does require a high nozzle temperature (between 270 and 300 °C), and a moderate print bed heat (40 to 60 °C).

Chemical properties

PA12 CF not only stands out for its mechanical and thermal properties, the large-format filament also boasts very good chemical resistance. The material can withstand exposure to various types of chemicals, including bases, alcohols, oils, and salts without adverse effect. This helps to increase the material’s durability for functional components.

Best Practices for Storing and Handling BigRep PA12 CF

To maximize PA12 CF’s resilient properties and final print quality, users should follow proper storage and handling guidelines for the material. The first thing to know is that PA12 CF is a highly hygroscopic material, meaning it easily absorbs moisture from the air. If the filament is stored in a humid environment, the material quality can degrade and moisture in the filament can cause printing issues, like stringing.

To avoid any moisture-related problems, BigRep advises storing PA12 CF filament spools in a dry environment, such as the BigRep SHIELD or BigRep Keep Dry Box. This is particularly important once the spools have been opened. You can also dry your PA12 CF filament before printing at 80°C for 6 to 8 hours.

In terms of handling, the material requires very high printing temperatures, so users should take necessary precautions and avoid touching the printer nozzle or melted filament. Additionally, good ventilation in the printing environment is recommended (as with all filaments), and personal protection equipment should be worn when performing any post-processing.

Use Cases: See How Customers Use BigRep PA12 CF

Within BigRep’s extensive filament portfolio, PA12 CF stands out as the most heat resistant and highest strength. These properties, in addition to its excellent chemical resistance, make the filament a good match for a broad range of industrial applications, including molds that can undergo multiple production rounds, jigs and fixtures, and various end-use components.

Along with BigRep’s other carbon fiber filament, HI-TEMP CF, PA12 CF has been of interest within demanding industries like aerospace and automotive, as well as in manufacturing, where custom tools that must withstand the pace and pressures of industrial processes are needed.

In the automotive sector, PA12 CF is ideal for the production of large-format end-use parts. Using the BigRep PRO platform, automotive manufacturers can benefit from the material’s excellent resolution and surface finish, cutting back significantly on time and money spent on post-processing—especially compared to near-net composite parts. The material’s excellent strength-to-weight ratio is also appealing to automotive adopters, who can increase a vehicle’s fuel efficiency by cutting down on weight without compromising on durability and performance.

Another notable use case for PA12 CF is carbon fiber molding. PA12 CF is engineered to withstand high temperatures and pressures, such as those present in an autoclave environment during the carbon fiber curing process. The filament can therefore be used to produce large and complex cure tools, which are then laminated with prepregs and placed in an autoclave to cure. Printing the mold directly can eliminate the need for a master pattern, resulting in a more streamlined carbon fiber production process.

For more specifications on BigRep PA12 CF or to purchase a spool of 2.85 mm filament, head to the BigRep Online Shop.