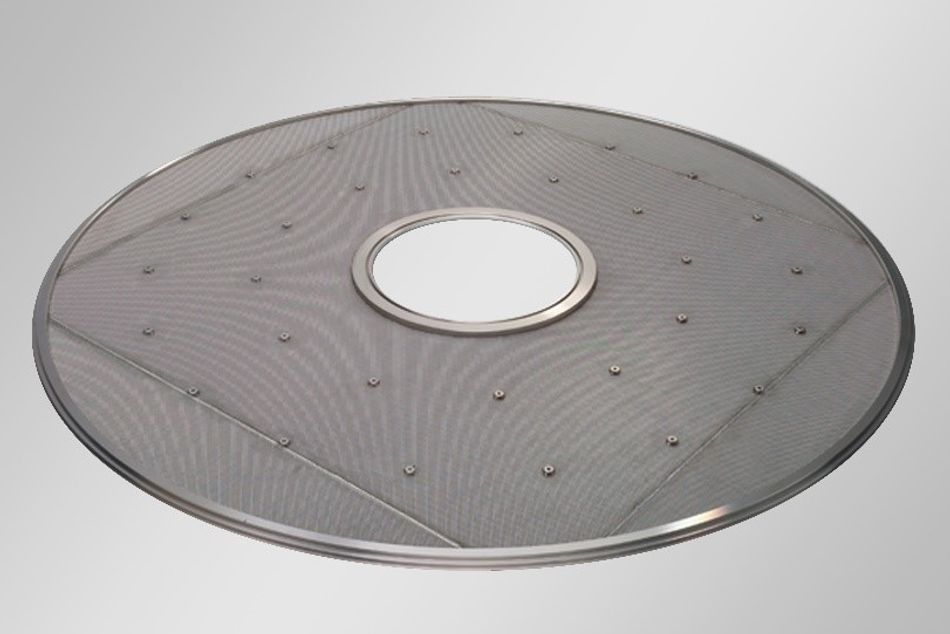

Wire mesh filters: precision and reliability for the process industry

Innovative wire mesh filters set new standards in medical technology, where smooth processes mean the difference between life and death. The same is true for the chemical industry. Here, filtration components must function perfectly even under extreme conditions and in contact with corrosive media.

Haver & Boecker's innovative wire mesh filters set new standards in medical technology, where smooth processes mean the difference between life and death. The same is true for the chemical industry. Here, filtration components must function perfectly even under extreme conditions and in contact with corrosive media. At ACHEMA 2024 from 10 to 14 June, the manufacturer will demonstrate why metal mesh is an economical and future-oriented solution for a wide range of applications in the process industry. In the run-up to the exhibition, free whitepapers are available to shed more light on these topics.

The white paper "When tiny meshes master mighty tasks" focuses on medical applications. Three practical examples illustrate the uses and benefits of wire mesh in this sector.

Focus on the patient's quality of life

The demands placed on medical technology products are high, as human lives depend on their performance and quality. This is even more true for filter components, which are used to remove unwanted particles from liquids and gases. Or to separate specific materials.

Wire mesh filters from Haver & Boecker are used in the manufacture of artificial kidneys (dialysis machines) or in stents to prevent blood clots from entering blood vessels.

Blood filtration in dialysis machines uses materials with mesh sizes between 10 and 100 nanometers to remove toxins while preserving essential blood cells and proteins. The flow characteristics are designed to cleanse the blood efficiently without affecting the patient's blood pressure.

Air filtration in ventilators uses HEPA or ULPA filters that trap micron-sized particles (around 0.3 µm for HEPA) to remove bacteria, viruses and other contaminants. Despite their high filtration efficiency, these filters still provide sufficient airflow for the patient to breathe. The ability to precisely determine the pore size and flow characteristics of Haver & Boecker's wire mesh filters enables them to be precisely tailored to medical requirements.

For grease-free cleaning, heating to 1000 °C is no problem. Advanced manufacturing processes and regular quality controls ensure maximum efficiency and reliability of the wire mesh.

Corrosion-resistant and sustainable

The second white paper, "Efficient filtration in the chemical and pharmaceutical

industry", also covers applications where chemical corrosion resistance and precise pore size are required for specific separation processes. The wire meshes used in these applications require high mechanical strength for long-term use under variable pressure conditions and thermal stability at different temperatures. Cleanability is also essential for reusability and durability.

The white paper highlights the importance of efficient filtration processes in the chemical and pharmaceutical industries to maintain high product quality. Various filter media are considered, with metal mesh laminates standing out for their robustness, durability and versatility. Their resistance to high temperatures and corrosion makes them ideal for process gas filtration and other demanding applications.

The ability to be cleaned and reused, combined with a long service life, makes a significant contribution to waste reduction and environmental protection. Compared to conventional materials such as ceramics or textiles, wire mesh filters offer significant advantages in terms of process stability and cost efficiency due to lower differential pressure and the ability to filter high throughput volumes without increasing system size. The result is superior filtration efficiency that minimizes production downtime and lowers the total cost of ownership while reducing environmental impact.

At ACHEMA 2024 you can see the product quality for yourself in Hall 3.0, Stand F38. Take the opportunity to learn first-hand about the many applications and benefits of this technology. Our representatives will be happy to assist you in person.