TechBlick's Electronics Reshaped Event - Berlin 2023

From stretching skin patches, to printed circuit boards, the Electronics ReShaped Event gave an insight into the exciting future of printed and flexible electronics.

From 17-18 October 2023, the "Future of Electronics Reshaped" global conference and exhibition took place at the Estrel Congress Center in Berlin, Germany. The event aimed to reshape the future of electronics, emphasizing additive, sustainable, flexible, hybrid, wearable, structural, and 3D electronics.

The TechBlick event gathered the global industry in Berlin, where the latest updates were unveiled, key conversations occurred, and new ideas and projects were initiated. Attendees benefited from a curated world-class agenda and masterclass program. They also had the opportunity to experience the latest technologies and products at 78 booths and connected with over 650 peers, partners, and customers from around the world. Notably, the exhibition had grown by 50% compared to its 2022 iteration.

The event also featured a unique hybrid package, allowing attendees to participate in the 2-day in-person event in Berlin and gain year-round access to all TechBlick live-online virtual conferences, masterclasses, and an on-demand library of previous presentations.

Wevolver attended the event and spoke to some of the exhibitions about their technology and its impact. We include just some of the exciting companies below.

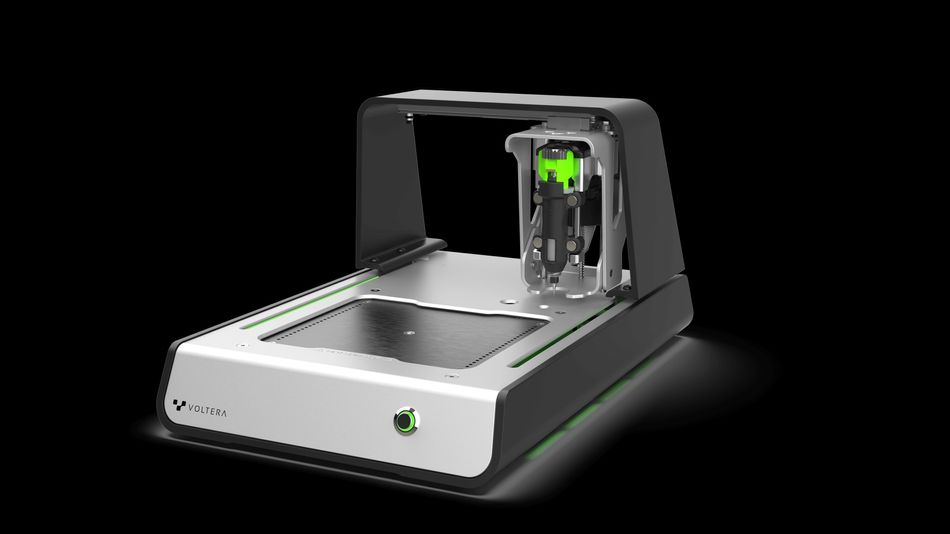

Voltera

Voltera is at the forefront of the future of electronics, emphasizing additive methods. They specialize in rapid prototyping platforms for printed electronics, catering to both traditional circuit boards and the evolving world of flexible, stretchable, conformable, and biocompatible electronics. Their product range includes the V-One, suitable for PCB prototyping and the Nova, which is ideal for printed electronics R&D, flexible electronics, microdispensing, and functional materials research.

Key Insights:

Unlocking New Possibilities: Voltera believes that the future of electronics will be cost-effective, lightweight, bendable, and seamlessly integrated into structures. Their platforms are designed to give users a competitive edge in this direction.

Materials Freedom: The additive technology they employ offers freedom in choosing inks and substrates. This opens doors to new applications in wearable electronics, biomedical devices, printed sensors, and more.

Efficiency in Design Iteration: Digital additive prototyping, as championed by Voltera, is faster than many alternative methods. It allows for quicker design iterations without the need for heavy investments or long waits for tooling.

Fraunhofer IAP

The Fraunhofer Institute for Applied Polymer Research (IAP) is dedicated to creating materials that are fit for the future. They focus on innovative solutions to address contemporary and upcoming challenges such as climate change, pandemics, energy transitions, structural changes, and evolving mobility concepts.

The institute emphasizes bioeconomy and sustainability by exploring sustainable raw materials and promoting a circular economy to decrease reliance on fossil energy sources. They believe that integrating innovative materials into products is crucial for energy transition and the development of new mobility solutions. Additionally, the institute works on new active ingredients, products, and processes for the medical and health sectors. Fraunhofer IAP supports the entire value chain, from the inception of innovative materials to the development of market-relevant prototypes.

Key Insights:

Addressing Global Challenges: Fraunhofer IAP is actively involved in finding creative solutions to global challenges, ensuring that materials and processes are sustainable and future-ready.

Promotion of Circular Bioeconomy: The institute has a roadmap for a circular bioeconomy in Germany, emphasizing the strategic research field of bioeconomy.

Engagement in Various Research Fields: From biopolymers and functional polymer systems to life sciences and bioprocesses, the institute covers a wide range of research areas.

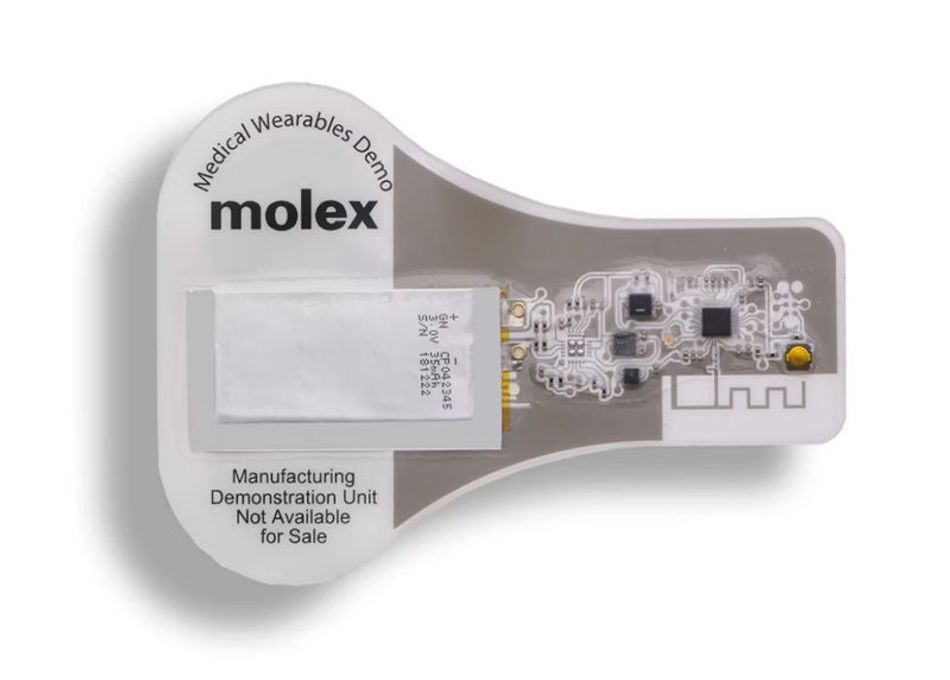

Molex

Molex, a global leader in connectivity solutions, is pioneering the development of smart skin patches that leverage hybrid printed electronics to enhance medical sensing capabilities. These patches are designed to improve patient outcomes by offering a range of functions:

Evolution of Smart Skin Patches: Modern smart skin patches have evolved from containing a single wired sensor to incorporating a myriad of functions. They utilize hybrid printed electronics, allowing for the integration of various electronic devices and noninvasive sensors onto a thin, flexible substrate. This advancement enables the creation of connected devices that can monitor vital signs or activity without invasive methods.

Key Insights

Demand for Connected Medical Sensing: The COVID-19 pandemic underscored the importance of remote patient monitoring. Smart skin patches offer a lightweight, comfortable, and portable solution for monitoring patients both within and outside healthcare facilities. They are also gaining traction for home health monitoring, sleep and brainwave activity tracking, and femtech applications like pregnancy monitoring.

Design and Architecture: Smart skin patches utilize flexible printed circuit technology and skin-safe adhesives. Their design can be customized based on the application, with options for disposable or reusable patches. Reusable patches have a design where only the skin-contacting electrodes are disposable, reducing waste.

Opportunities and Challenges: Designing smart skin patches involves integrating various electronic devices, including sensors, batteries, microcontrollers, and RF antennas. Achieving system reliability requires expertise in multiple engineering disciplines, from material science to electronic component reliability. Ensuring product performance and meeting regulatory compliance standards are also paramount.

Themes explored during the event included printed flexible hybrid electronics, structural and in-mold electronics, sustainable electronics, wearable electronics, electronic textiles, smart skin patches, continuous vital signs monitoring, 3D printed electronics, and many more.

Stay up to date on TechBlick events by following their Wevolver profile.