Printed Electronics at the Forefront of Wearable Combat Devices

How Voltera's NOVA materials dispensing system can empower defense and military organizations to develop cutting-edge wearable devices for optimal physical and cognitive performance in the field.

In the course of military history, functional wearables and wearable devices have played a central role in military operations, providing both protection to troops and enhancing the capabilities of soldiers. From the development of forged plate armor in the middle ages, which replaced far heavier chain mail while providing better shielding, to the introduction of portable compasses in the 19th century, which transformed a soldier’s navigational capabilities, innovation in defense wearables has long been driven by a need to improve comfort and performance. The same is true today, as we advance into a new era of intelligent technologies, sensors and connectivity.

This shift towards increasingly sophisticated, intelligent wearables in the defense sector is enabled by cutting-edge fabrication methods, such as Voltera’s NOVA solution for printing electronics. This technology is proving to be key in the development of next-generation wearables that offer improved, adaptable comfort, continuous health monitoring, and discreet, real-time communication to soldiers in the field. In this article, we will be looking at why the NOVA platform is particularly well suited to wearable defense applications and examine three key application areas where the technology is revolutionizing military wearables.

Voltera’s NOVA, a platform for innovation

Canadian company Voltera was founded in 2013 with the aim of making electronics development more accessible, agile, and versatile. Its NOVA platform, first released in 2022, is the embodiment of this goal, offering users a benchtop materials dispensing system capable of rapidly printing screen printable inks (1,000-1,000,000 cP) onto a wide variety of substrates, including rigid, flexible, stretchable, and novel materials.

The platform can print functional electronics and sensors—including multilayer circuits—without the need for tooling, making it a valuable tool for electronics prototyping and development, materials testing, and manufacturing custom or low-volume devices. In the context of defense, the benefits of being able to rapidly iterate circuit designs for wearable devices and to make on-the-fly changes for improved functionality can’t be overstated, particularly for devices that have the potential to be life saving in the field.

Another key advantage of Voltera’s NOVA platform for end-users in the defense sector is that it simplifies supply chains. With its modest footprint and intuitive user interface, NOVA can be used in-house. This means that wearable devices can be developed securely and near the point of need. For an industry like defense, where having a competitive technological advantage can mean the difference between a successful mission and a critical failure, NOVA therefore provides a vital capability.

Now, without further ado, let’s look at some of the application areas where Voltera’s NOVA platform is unlocking new opportunities for mission-specific wearable electronics.

Wearable heaters for enhanced thermal management

One area where electronics printing can improve a soldier’s comfort and performance is thermal management. Adequate thermal management is essential for troops that are deployed in cold or harsh environments, helping to protect them from temperature-related injuries like frostbite and hypothermia, while also ensuring optimal physical and cognitive performance. Though the defense sector has seen vast improvements in this area in the last century—such as the development of lightweight, highly insulating fabrics—there is a continual push for more innovation in thermal management, with a particular focus on wearable heaters.

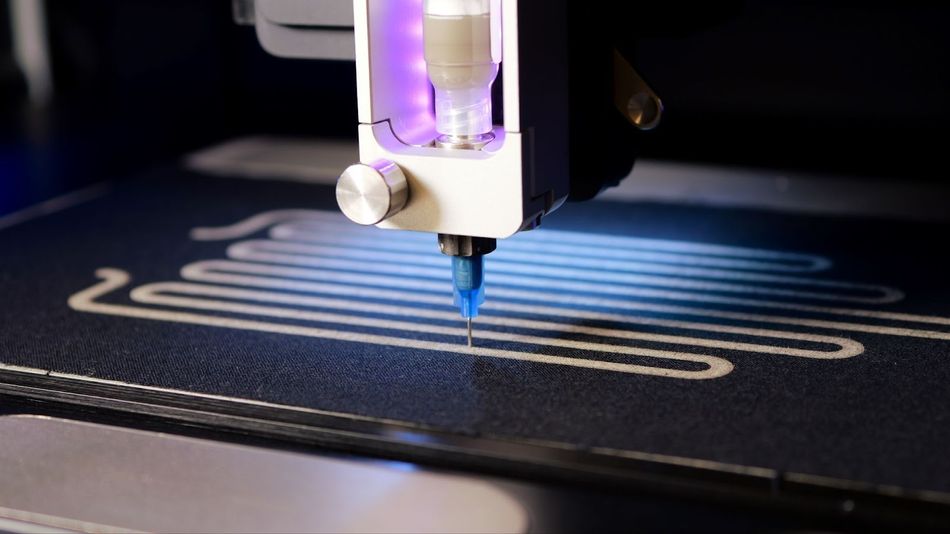

With the ability to print conductive traces onto wearable materials, including tight-knit cotton, nylon, and Kevlar, Voltera’s NOVA platform is well positioned to drive the developments of wearable heating elements with minimal weight addition and without compromising the flexibility of the gear. In fact, the technology has already been used to such ends.

In one use case, Voltera demonstrated how to print a heated glove, leveraging NOVA to dispense silver conductive ink onto a cotton substrate in the shape of a hand.[1] The ink material used, ACI SH5025 Printed Fixed Resistance Heater Ink, was selected because it is specifically engineered for heating applications and for use with elastomeric substrates. This use case resulted in a wearable heating element capable of reaching up to 40°C when powered by a 12V power source. For comfort and safety, the heating element is contained with an internal liner that makes direct contact with the wearer’s hand. The device could also be adapted for enhanced portability through the integration of an embedded power supply.

In a similar proof of concept, Voltera printed a wearable pocket heater that used Celanese Intexar (PE874) silver ink and TPU as a substrate.[2] This flexible heating element—printed in less than 15 minutes—was integrated directly into a denim pocket and, when connected to a battery pack stored in the pocket, reached up to 45-50°C within a minute. This localized, wearable heating device could also be adapted for other applications, like in a military jacket pocket or boots to keep troops warm in harsh, cold conditions.

Wearable sensors for continuous health monitoring

In the military, health monitoring is a key component in maintaining operational readiness, taking a preventative approach to injury and illness, and enhancing recovery and rehabilitation. Traditionally, monitoring a soldier’s condition required periodic manual checks by medics. However, keeping a close eye on individual soldiers’ health is not always possible in field missions. Fortunately, wearable health sensors are making continuous health monitoring possible at scale, ensuring that every soldier is accounted for.

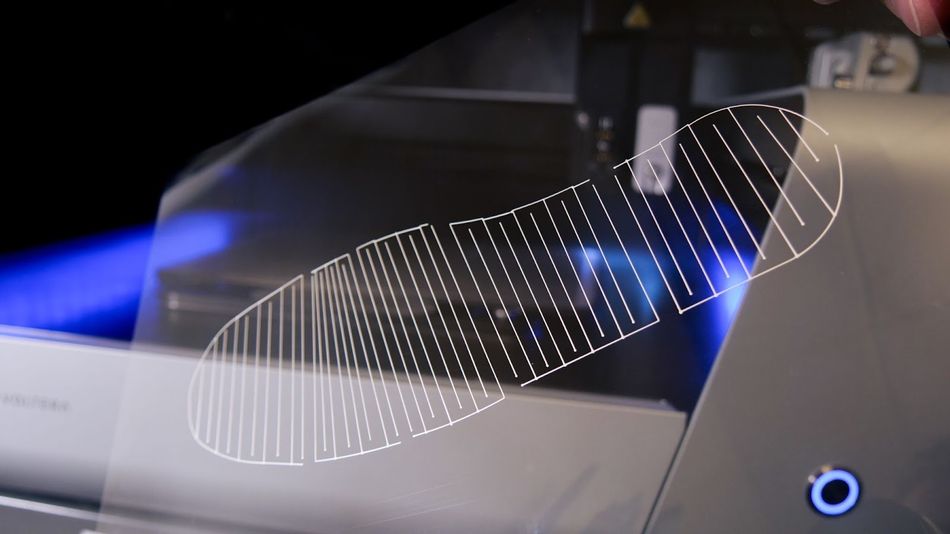

NOVA can play a role in the development of these wearable devices, which can track an individual soldier’s health and vitals while in training or in the field. By printing biocompatible materials, like gold and silver inks, onto flexible substrates that conform to the body, it is possible to deploy discreet monitoring devices that soldiers can wear without compromising comfort.

For example, Voltera conducted a proof of concept in which it printed an insole embedded with force sensitive resistors (FSR) capable of detecting physical pressure and weight distribution.[3] The sensors, printed using stretchable silver ink and a TPU substrate, were applied to a foot-shaped carbon sheet and connected to a breadboard in order to function. This technology could be further developed by defense organizations for posture and gait analysis as well as injury tracking. For example, sensors could be strategically placed on the heel or ball of the foot to monitor weight distribution and balance in real time, providing vital insights into whether a soldier is injured (i.e. if they are relying more on one leg) or fatigued (i.e. if their gait pattern changes).

Electronics printing has also been used in the development of electrocardiogram (ECG) electrodes, which are placed on the skin to monitor the heart’s electrical activity. In one study, Voltera used biocompatible gold ink and stretchable silver ink on a TPU substrate, to create a set of dry ECG electrodes, which are easier and more comfortable to wear than conventional ECG electrodes, demonstrating NOVA’s ability to drive innovation in this area.[4] In a defense context, similar ECG sensors could be integrated into shirts or chest straps for real-time monitoring of vitals, giving medics continuous data and alerting them to notable changes (i.e. elevated heart rate), which could indicate stress or danger.

Of course, insole pressure monitors and dry ECG electrodes are just the tip of the iceberg for printed health monitoring devices: printed sensors could also be developed to track health metrics like hydration, fatigue, and more, to ensure troops are at their optimal physical and cognitive performance.

Body-worn printed batteries for better communication

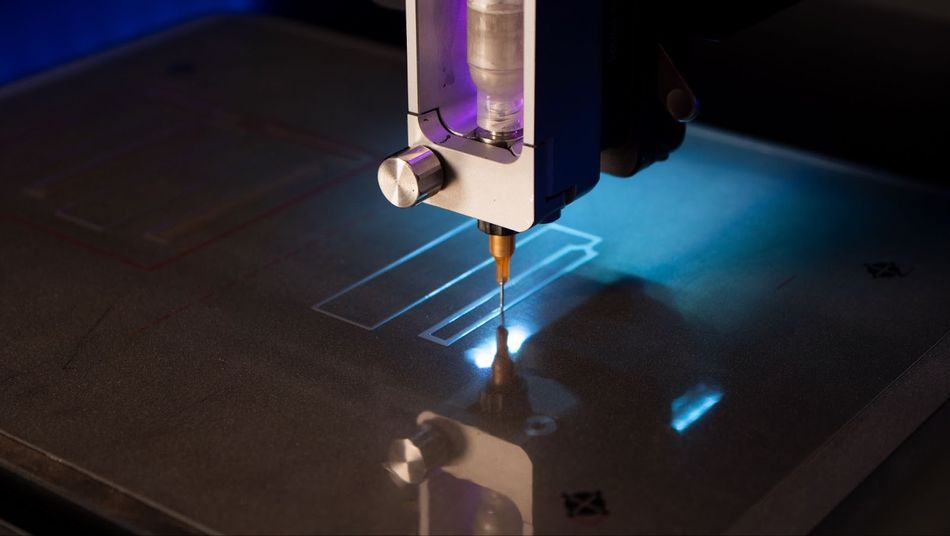

Printed electronics can also transform the state of wearable communication devices, leading to improvements for real-time, hands-free communication that can help track troops and equipment in the field. Voltera’s NOVA platform in particular can be used to develop and print ultrathin, compact batteries that can be worn alongside communication devices, powering anything from encrypted radios, to GPS trackers, to motion-tracking sensors and unburdening soldiers as they are increasingly equipped with networked devices.[5]

The potential of printing body-worn batteries is great in the defense sector and Voltera recently demonstrated how its NOVA platform can be used to exploit this potential. In one study, the company printed an ultrathin (500 µm), seven-layer zinc-manganese battery on a flexible PET substrate.[6] This proof of concept demonstrated how NOVA can print compact energy storage devices that can be customized in terms of shape and size to meet application requirements. The printing process can also be used with other types of inks, including lithium cobalt oxide, less flammable carbon nanotubes, and non-flammable vanadium oxide.

For defense applications, NOVA could therefore print compact batteries that conform to the wearer and provide power to wearable electronics, ensuring round-the-clock communication and function, while eliminating bulky equipment and wires.

Conclusion

The NOVA printing platform thus has the potential to be an indispensable tool to defense organizations, empowering them to enhance combat-specific wearable technologies that improve everything from thermal management, to health monitoring, to communications. To learn more about Voltera’s industry-leading solution and its applications in the defense sector, don’t hesitate to get in touch with a member of the Voltera team.

References

[1] Printing Silver Conductive Ink on Cotton Fabric [Internet]. Voltera, 2025. https://www.voltera.io/use-cases/white-papers/printing-silver-conductive-ink-cotton-fabric

[2] Wearable pocket heater with stretchable silver on TPU [PDF]. Voltera, 2025.

[3] Insole pressure sensor with stretchable silver on TPU [PDF]. Voltera, 2025.

[4] Printing ECG Electrodes with Biocompatible Gold Ink on TPU [Internet]. Voltera, 2025. https://www.voltera.io/use-cases/white-papers/printing-ecg-electrodes-biocompatible-gold-ink-tpu

[5] Lafontaine, Dan. Conformal battery unburdens Army's networked Soldiers [Internet]. U.S. Army, July 17, 2013. https://www.army.mil/article/107362/conformal_battery_unburdens_armys_networked_soldiers

[6] Printing a Magnesium Zinc Battery with Saral Inks on PET [Internet]. Voltera, 2025. https://www.voltera.io/use-cases/white-papers/printing-magnesium-zinc-battery-saral-inks-pet