Injection Molded Plastic Parts for Scientific and Laboratory Equipment Applications

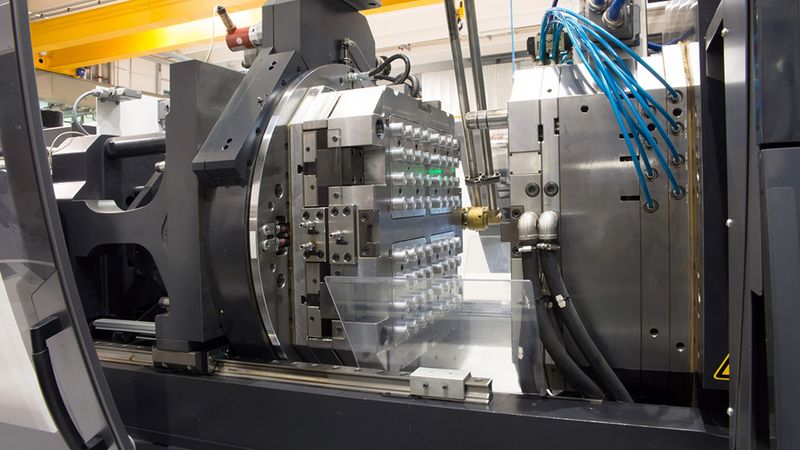

Injection molded plastic parts have become an essential solution for the production of laboratory and scientific equipment, providing accuracy, repeatability, and scalability.

Scientific and laboratory equipment demand components that meet high standards of precision, durability, and chemical resistance. From analytical instruments to sample handling devices, each part must perform reliably in critical applications. Injection molded plastic parts have become an essential solution for the production of laboratory and scientific equipment, providing accuracy, repeatability, and scalability. RPWORLD delivers advanced manufacturing solutions that ensure high quality and functionality while supporting innovation in scientific applications.

Precision and Reliability in Laboratory Components

Laboratory equipment often requires complex geometries and tight tolerances. Even minor inconsistencies can impact the accuracy of measurements or the efficiency of laboratory workflows. Injection molding provides the precision needed to create components that fit seamlessly into assemblies, maintain proper alignment, and withstand repeated use.

For early stage development or specialized experiments, plastic injection prototypes for small batches are a valuable tool. They allow scientists and engineers to test designs, validate functionality, and refine components before scaling production. RPWORLD offers high quality prototype services that enable rapid iteration while ensuring dimensional accuracy and material performance.

Material Selection for Chemical Resistance and Durability

Laboratory components are exposed to chemicals, sterilization processes, and mechanical stress. Choosing the right material is critical to ensure longevity and safety. Injection molding supports a wide range of engineering plastics with properties such as chemical resistance, high temperature stability, and electrical insulation.

For applications that require flexibility or specialized sealing capabilities, liquid silicone rubber molding services provide additional functionality. LSR molded parts offer excellent thermal stability, biocompatibility, and durability, making them ideal for seals, gaskets, and flexible components in scientific instruments.

Design Flexibility for Complex Applications

One of the key advantages of injection molding is its ability to produce complex parts with integrated features. Snap fits, channels for fluids, mounting points, and precise cavities can all be molded directly into components, reducing the need for secondary assembly. This design flexibility allows manufacturers to produce functional parts that enhance laboratory workflows and improve device performance.

RPWORLD’s expertise in plastic injection prototypes for small batches and liquid silicone rubber molding services ensures that laboratory components meet functional and regulatory requirements without compromising quality or performance.

Scalability from Prototype to Production

Scientific and laboratory equipment projects often start with low volume or experimental runs before moving to larger production. Injection molding allows seamless scaling from prototypes to full production while maintaining consistent quality. RPWORLD’s manufacturing capabilities support this transition efficiently, ensuring that every part meets strict tolerances and material specifications at any production scale.

Quality Control and Compliance

Laboratory components must meet stringent quality standards to ensure reliability and safety. Injection molding processes incorporate precise process control, in-process inspections, and final quality verification. RPWORLD integrates rigorous quality assurance practices throughout production, guaranteeing that molded parts are free from defects and fully compliant with performance requirements.

Partnering with RPWORLD for Laboratory Equipment Solutions

RPWORLD delivers end-to-end injection molding services tailored for scientific and laboratory applications. Their capabilities include plastic injection prototypes for small batches for testing and rapid design iteration, as well as liquid silicone rubber molding services for flexible and specialized components. With advanced tooling, experienced engineers, and strict quality control systems, RPWORLD ensures that each component meets the demanding needs of laboratory equipment manufacturers.

By combining precision, material expertise, and scalable manufacturing solutions, RPWORLD supports innovation in scientific instruments and laboratory devices. Clients benefit from reliable parts, accelerated development timelines, and consistent quality across every batch.

Conclusion

Injection molded plastic parts are essential for modern scientific and laboratory equipment, offering precision, reliability, and design flexibility. With access to plastic injection prototypes for small batches and liquid silicone rubber molding services, manufacturers can develop components that meet stringent performance and safety standards. RPWORLD provides the expertise, technology, and quality systems to ensure that laboratory equipment components are functional, durable, and compliant, helping scientific innovations reach the market efficiently.