Design Guidelines for Manufacturing and Assembly - How to Reduce the Quantity of Parts

Under the premise of ensuring the function and quality of the product, simplified design and fewer parts can reduce product cost, shorten product development cycle and improve product development quality. Here are the ideas on how to reduce the quantity of parts

Photo by Alireza Hatami on Unsplash

Under the premise of ensuring the function and quality of the product, simplified design and fewer parts can reduce product cost, shorten product development cycle and improve product development quality. Here are the ideas on how to reduce the quantity of parts as below:

1. Inspect each part and take into consideration of the possibility of removing it

From figure 1-1, we can see in original design, the product is assembled from part A-a sheet metal part and B-a machined part by welding, performing a clip function.In improved design, part B is removed and the function of clip is merged into the sheet metal part.

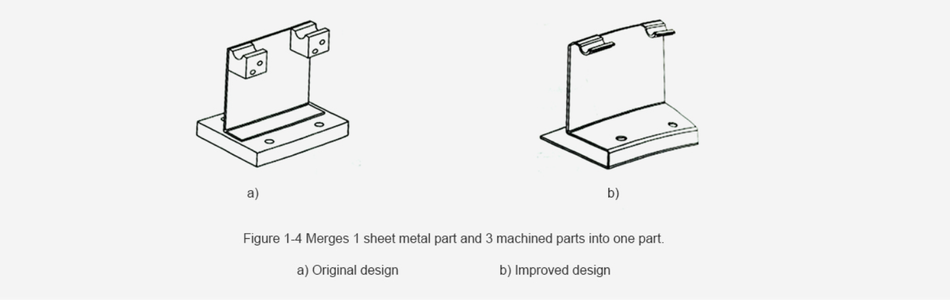

2. Merge adjacent parts into one

The criteria for judging whether adjacent parts can be merged are as follows:

1) Do adjacent parts have relative motion?

2) Shall adjacent parts be composed of different materials?

3) Does the merger of adjacent parts prevent the fixing, disassembly and maintenance of other parts?

4) Does the merger of adjacent parts make parts manufacturing complex and increase the total cost of the product?

If the answers are all “No” to the four questions above, then adjacent parts may merge into one. Figure 1-1 shows an example of merging adjacent parts A and B into a part A.

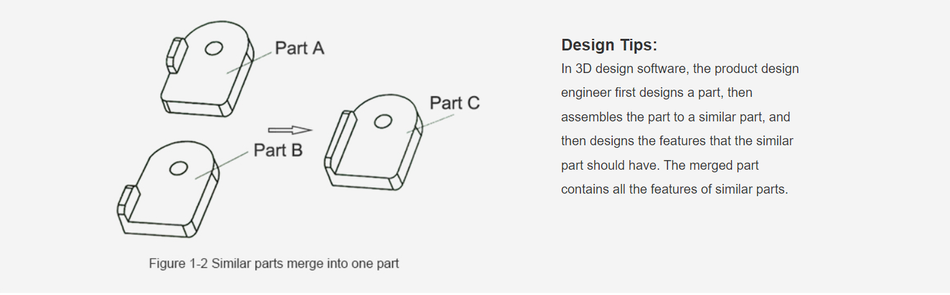

3. Merge similar parts into one

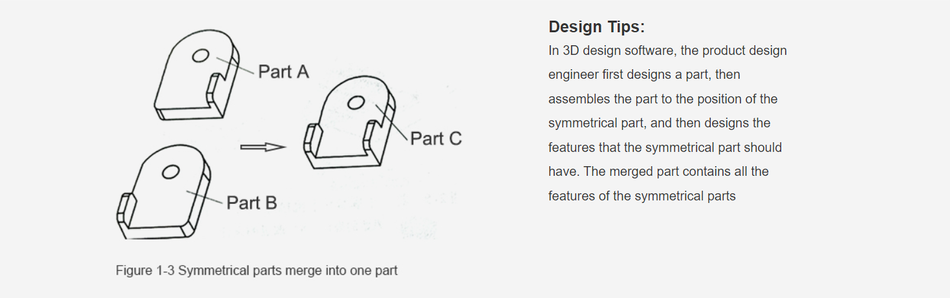

4. Merge symmetrical parts into one

5. Avoid overly robust design

Engineers can avoid overly robust product designs by relevant theoretical analysis and simulation, as well as prototypes and testing.

Too robust design will increase the number of parts and the complexity of the product, resulting in an increase in product cost.

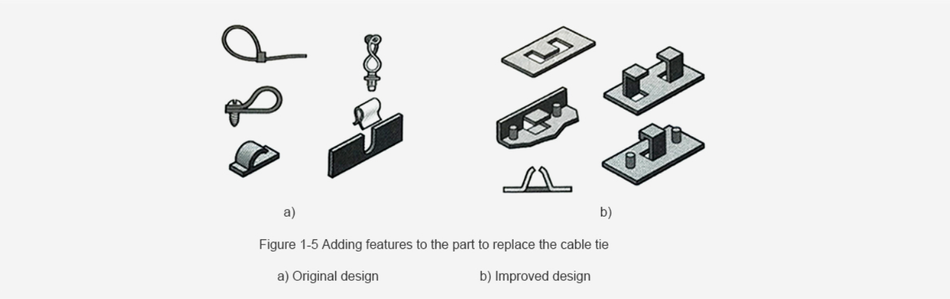

6. Choose manufacturing processes reasonably and design multifunctional part

7. Remove labels

To mark parts, labels are often needed, which are usually fixed by bonding, snapping or fastener. Sometimes the label contents can be displayed on the parts by injection molding, die casting, stamping etc., so the labels can be canceled as shown in Figure 1-6.

8. Use new technology

When it is difficult to simplify the product by a common design, try new technologies.