Choosing the Right Solder Paste for Additive Electronics

Everything you need to know about choosing the right solder paste when printing electronics, from composition and function to particle size and application.

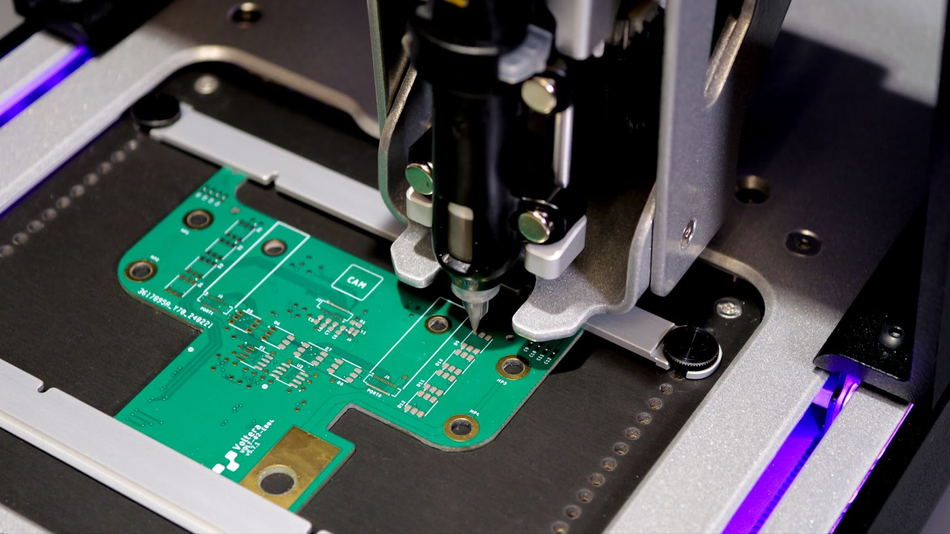

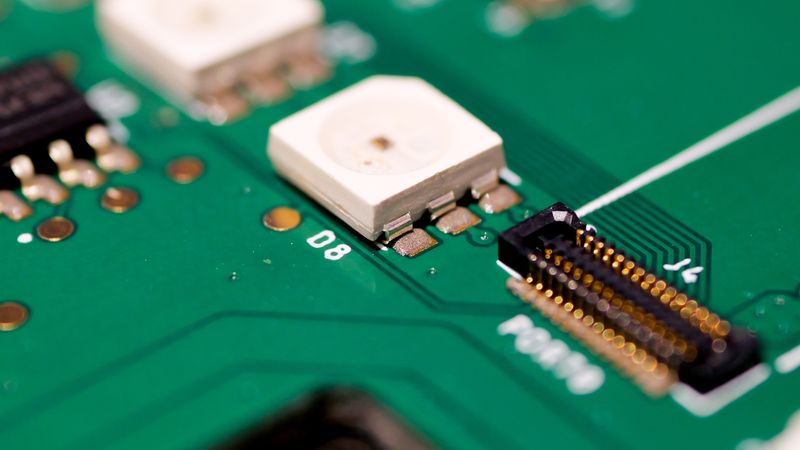

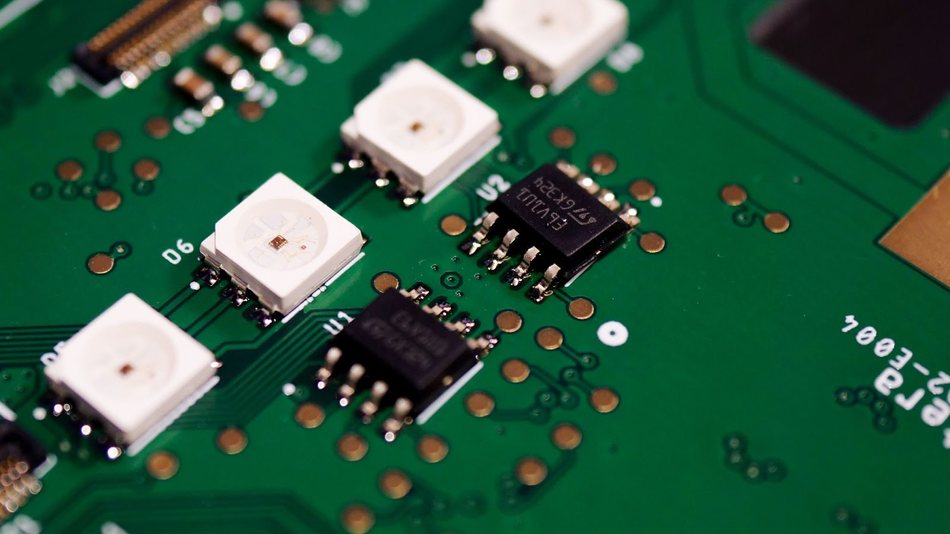

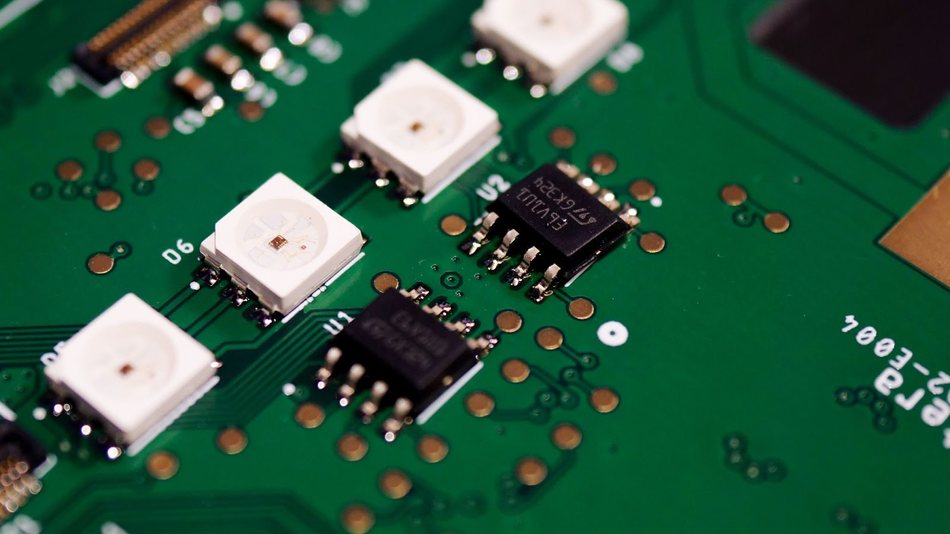

Electronic components and solder paste. Source: Voltera.

Additive electronics is growing in popularity as a prototyping and production process for printed circuit boards (PCBs). The method, which encompasses printing technologies like Direct Ink Writing (DIW), takes a different approach to conventional PCB production, selectively adding conductive and dielectric materials to a substrate rather than removing excess material. This has several benefits, including more efficient, agile, and sustainable PCB prototyping.

Despite the key differences between additive and subtractive electronics production, PCB production necessitates a few key elements: a substrate (i.e. the board), electronics components, and a solder material, such as solder wire or solder paste. In additive electronics, solder paste plays a critical role, ensuring that electronic components are kept in place and that electrical and mechanical connections are maintained after reflow for optimal PCB performance and functionality.

In this article, we’ll be looking closer at the role of solder paste in PCB production, the various types of solder paste that exist on the market, and how to choose the right solder paste when working with an additive PCB production method, such as Voltera’s DIW platforms.

What is solder paste?

Before diving into how to choose the right solder paste when working with an additive electronics technology, let’s first cover the basics. Solder paste is a sticky fluid that is made up of a powdered metal alloy (called solder) and a chemical agent (called flux). When the flux is mixed with the powdered metal, it creates a viscous paste that can be extruded through a nozzle. The flux also functions as a protective matrix for the metal particles, preventing them from oxidizing. (This composition is different to more conventional solder wire, which is sold as a solid wire infused with flux, typically applied manually to circuit boards manually using a soldering iron.)

When using an additive electronics printing method, solder paste is applied to circuit boards in a specific pattern or at specific points. When this application is complete, the entire board is heated, which allows the metal particles in the paste to melt and form a bond. This is the reflow process.

The function of solder paste

Solder paste has a dual function in additive PCB production. First, solder paste holds components in place, which is vital in an additive approach since layers and traces are built up on the substrate rather than etched away. Second, in the reflow process the metal particles in the solder paste are melted and fused, creating a strong mechanical bond between leads, conductive traces, and conductive pads. This also ensures low-resistance electrical conductivity.

The dual function of solder paste in additive PCB production—physically securing components and ensuring optimal conductivity—is key to ensuring the structural integrity and long-term performance of the device.

Common types of solder pastes

We know that solder paste is made up of solder and flux, but it is also important to understand that there are various types of solder paste based on different flux materials, solder alloy composition, and particle size.

Flux is essential for removing oxides from metal surfaces and promoting solder wetting. There are three main types of flux material, each of which has different properties when it comes to corrosiveness, activity, and cleaning. They are:

Rosin flux: This type of flux is derived from pine tree resin and is mixed with a solvent. Rosin-based flux can withstand high soldering temperatures and is non-corrosive. It is typically not water-soluble and requires solvent-based cleaning after reflow to remove leftover flux.

Water-soluble flux: This type of flux, made from organic acids and solvents, is highly active. After reflow, the flux must be thoroughly washed away using water to avoid any corrosion.

No-clean flux: This type of flux uses synthetic resins and low-activity acids. It leaves minimal residue after reflow and does not require cleaning, making it suitable for high-volume PCB production.

Solder composition can also vary and influence factors including performance, handling characteristics, environmental impact, and compatibility with other materials. There are two main solder categories—both of which are based on tin since it has a low melting point. They are:

Lead-based solder: Lead-based solders, usually an alloy of tin and lead, were for years the standard in electronics production. This type of solder has the benefit of a low melting point (~183°C), which makes it easy to work with and minimizes thermal stresses on PCB components. Lead-based solder also demonstrates good wetting properties for smooth reflow. All that said, lead is highly toxic and poses health and environmental risks during manufacturing, use, and disposal. Due to this, its use has been heavily restricted in the EU by the Restriction of Hazardous Substances Directive (RoHS) since 2006. Additionally, lead is incompatible with certain conductive materials, such as silver inks.

Lead-free solder: Lead-free solders are typically tin-based alloys containing copper, silver and/or bismuth. These alloys have the benefit of being more environmentally friendly and non-toxic than their lead counterparts (as well as compliant with RoHS standards in most cases). Lead-free solder is also compatible with silver inks, commonly used in additive electronics. They generally have higher melting points, which can introduce more thermal stress and require tighter process control.

Finally, metal particle size in the solder also influences the solder paste’s overall properties. To guide users, solder pastes are characterized by different IPC types, which identifies various solder powder sizes. The scale used for measuring particle size ranges from T1 to T8, where the lower numbers indicate larger particle sizes. In general, finer particle sizes offer better printing resolution, making them suitable for high-density PCBs and miniaturized components. Larger particle sizes are less prone to oxidation and are suitable for larger components and through-hole applications.

How to apply solder paste

Generally speaking, solder paste is selectively applied to circuit boards. There are different approaches to applying solder to electronic circuits: hand soldering or automatic soldering.

Hand soldering

With hand soldering, you need a variable-temperature soldering iron, soldering wire, and flux. Hand soldering is suitable for:

Prototypes

epairs and rework

Low-volume production

Double-sided assemblies where selective heating is needed.

Voltera supplies low-temperature solder wire specifically formulated to work with silver-based conductive inks. This is important because conventional solders can form unwanted intermetallics with silver, degrading the reliability of printed traces.

Automated soldering

Automated dispensing and reflow provides greater precision, repeatability, and throughput. For example, electronics printers—like Voltera’s V-One and NOVA systems—offer precise and reliable solder paste dispensing. In these systems, solder paste is contained in a cartridge and dispensed directly onto the board with the ability to select specific solder pads and reprint on the fly.

The V-One is a compact desktop PCB printer that also includes a built-in reflow heater, allowing for a full print-to-reflow workflow in one device—ideal for in-house PCB prototyping and electronics education. The NOVA, Voltera’s materials dispensing platform, is designed for larger boards, multi-layer circuits, and flexible electronics. It offers greater precision and flexibility, making it ideal for research labs and low-volume production where circuit flexibility, multilayer construction, and print accuracy and repeatability are paramount.

Voltera solder pastes

Voltera offers a range of solder pastes, including lead-based and lead-free compositions.

Tin-lead solder paste (Sn63Pb37) contains 63% tin and 37% lead. This solder paste offers a strong bond and can withstand higher temperatures than its lead-free counterpart. It is ideal for printing solder pads onto traditionally manufactured PCBs. As mentioned, however, the tin-lead solder paste has limitations when it comes to printing PCBs on the V-One since it is not compatible with printed silver inks, and it requires good ventilation due to lead.

Lead-free solder paste (Sn42Bi57.6Ag0.4) is made up of 42% Tin, 57% Bismuth, and 0.4% Silver. The inclusion of bismuth offers a lower reflow temperature (190°C for 30 seconds) and makes the solder paste compatible with printed silver traces. Working with this solder paste requires precision and a gentle touch for the optimal performance.

Both lead and lead-free solder pastes use a rosin flux, which translates to low corrosion compared to water soluble flux. Voltera also offers both Type 4 (20-38 microns) and Type 5 pastes (10-25 microns). The former is ideal for standard sized circuits and reflows well on printed pads; the latter is ideal for smaller, more precise components.

Matching the solder paste to an application

Solder paste being reflowed using V-One . Source: Voltera.

Solder paste being reflowed using V-One . Source: Voltera.

Ultimately, choosing the right solder paste comes down to the application. As we’ve seen throughout this article, different types of solder paste have distinct properties, which make them either viable or less than ideal depending on what type of PCB is being printed and what materials are used. For example, you wouldn’t choose a lead-based solder paste to solder a printed circuit with silver ink traces, since the two are incompatible.

Looking specifically at Voltera’s solder pastes, each is suitable for a set of applications. Let’s take a closer look:

Solder paste type | Suitable applications |

This lead-free solder paste is a reliable choice for printing standard-sized circuits on the V-One, since it is compatible with the company’s conductive silver inks. | |

This lead-free option with finer particle sizes is a good fit for miniaturized components with fine traces. | |

This tin-lead solder paste is ideal for printing onto traditionally manufactured PCBs with a HASL surface finish. This solder paste also facilitates rework. |

It is also worth mentioning that Voltera sells a solder wire (Sn42Bi57Ag1) with a flux of 2.2%, which is compatible with its conductive inks and enables users to manually solder double-sided boards.

Conclusion

Ultimately, understanding the role that solder paste plays in additive electronics can empower users to choose the optimal product when printing PCBs. The right solder paste used in combination with one of Voltera’s DIW printing platforms can result in circuits that benefit from excellent precision as well as mechanical and electrical stability.

If you’re into printed electronics, Voltera regularly hosts webinars to help you go deeper. Register for Voltera’s upcoming webinar, How to Connect Circuits: Connector Technologies and Integration Strategies, running 11 a.m.-12 p.m. ET on Thursday, September 25, 2025.