Artificial Intelligence Assisted Architected Materials in Additive Manufacturing

The current advancement in multi-material additive manufacturing technologies has provided unique opportunities to create 3D printed structures with not only complex geometries at several length scales, but arbitrary deposition of multiple materials (i.e., soft or hard) in 3D space.

This article is a part of our University Technology Exposure Program. The program aims to recognize and reward innovation from engineering students and researchers across the globe.

The current advancement in multi-material additive manufacturing technologies has provided unique opportunities to create 3D printed structures with not only complex geometries at several length scales but arbitrary deposition of multiple materials (i.e., soft or hard) in 3D space.

The interplay between geometry and material can offer designers unbounded freedom to push the limits of traditional materials and introduce a new class of engineered material with unprecedented properties and functionalities.

Finding an optimal combination of geometry and material deposition to achieve target properties is, however, not straightforward and requires efficient methods that evaluate all possible designs within the domains of interest in a reasonable time.

Artificial neural networks are powerful tools that may help designers bypass such “try-and-error” approaches and speed up the process of extracting corresponding (micro-)architectures and material distributions for any desired target properties.

Our aim is to propose new design approaches and (bio)fabrication techniques for creating (bio)materials with tailor-made properties. We use two frontier technologies namely multi-material 3D printing and AI to create various types of “digital materials” with rare properties (see the news covering our work in [1]).

How does the design platform work?

One of our design bases is rooted in the concept of the mechanical metamaterials. These engineered materials own their mechanical properties from their microstructures rather than their chemical compositions. For instance, most of the existing metamaterials are composed of periodic unit cells, which results in spatially uniform properties and symmetric deformations under loading. The overall performance of such materials is, however, very sensitive to defects. Therefore, we introduced randomness in the design of mechanical metamaterials to create aperiodic microstructures resulting in a haphazard distribution of material properties (i.e., elastic stiffness and Poisson’s ratio) within the structure [2].

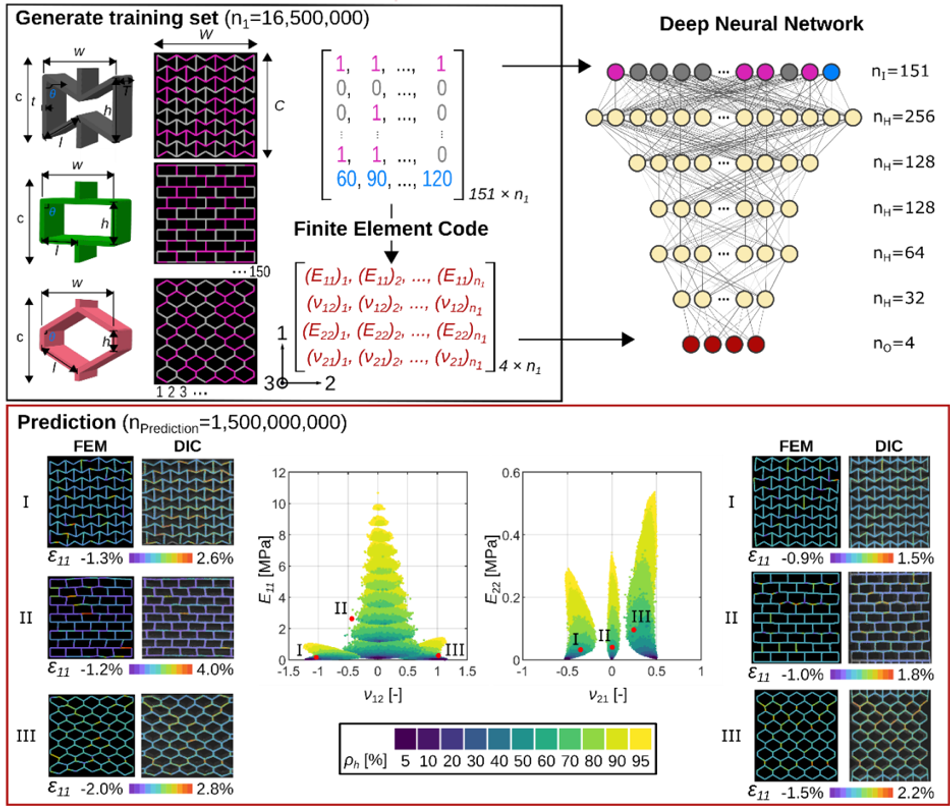

Our disordered microarchitectures and their multi-material variational distribution across space within a lattice can provide remarkable and unique anisotropic elastic properties and even extremely rare event material properties (e.g., a combination of double-auxeticity and high elastic moduli) [3]. However, evaluating the entire mechanical design space is necessary to find these rare event designs, which can be more challenging than finding a needle in a haystack. In this “curse of dimensionality”, the number of designs that need to be evaluated is so large that high-speed models and highly parallelizable algorithms are required. Computational models, such as finite element models, are also not fast enough for this purpose. To boldly tackle this challenge, we utilized artificial intelligence (AI) techniques to accelerate the evaluation process of the mechanical properties of such structures (Figure 1). After training a series of deep neural networks, we rapidly predicted the mechanical properties of random mechanical metamaterials (Figure 1). Thanks to the resulting ultra-fast deep learning model, we found mechanical metamaterials that feature remarkably unusual mechanical properties [2].

On top of that, we took the advantage of the ‘digital materials’ concept, in which micro-scale discretization of materials can be generalized to macro-scale materials with an incredibly large array of properties. Combining such an infinite array of possibilities with AI techniques has allowed us to generate the most optimal materials with tailor-made properties.

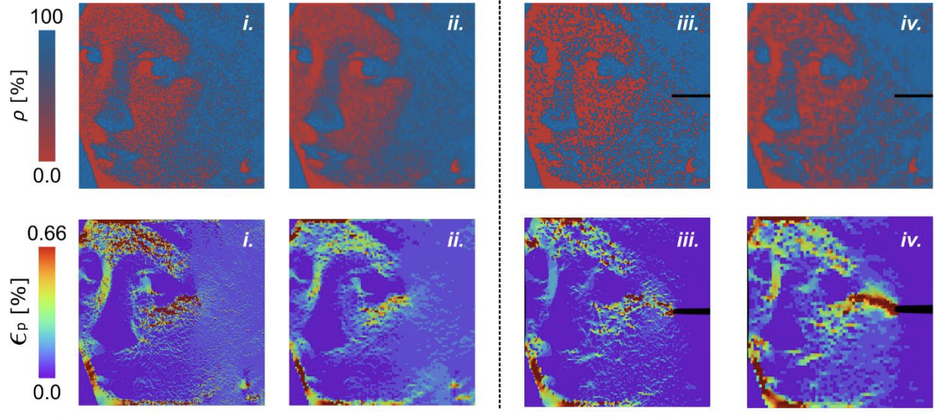

In our designs, we benefit from the design motifs that exist in nature (e.g., multi-scale hierarchy and functional gradient [4]). The combination of the hard-soft material components at multiple length scales, and AI neural networks has enabled us to reduce the dimensionality of the problem by using coarse-graining approaches [5] (Figure 2). Such implementation decreased the computing time of our computational models by several order of magnitudes without affecting the accuracy of the predicted mechanical properties of our materials [5].

Applications

We envision several biomedical applications including design and fabrication of orthopaedic (metallic) implants and their connections to the soft tissues (i.e., tendon or muscle), developing in vitro models to investigate cell mechanics and their interactions with 3D printed implants, and smart exoskeletal and wearable medical devices with adaptive shape morphing capabilities. We hope our proposed design strategies can impact the public health sector and improve the life quality of individuals and their societal well-being.

We are researchers (PhD candidates: Helda Pahlavani, Mauricio C. Saldivar, PI: Dr. Mohammad J. Mirzaali) at Bio-Tie (BIOmimetic Tissue InterfacEs) lab. We are members of the “Biomaterials and Tissue Biomechanics” section led by Prof. Amir Zadpoor, at the Department of Biomechanical Engineering, Delft University of Technology. Our multidisciplinary research meets at the crossroads of mechanical engineering, material science, biomedical engineering, and biomechanics.

References

[2] Pahlavani, Helda, Mohammad Amani, M. Cruz Saldívar, Jie Zhou, Mohammad J. Mirzaali, and Amir A. Zadpoor. 2022. Deep learning for the rare-event rational design of 3D printed multi-material mechanical metamaterials. Communication materials, in press.

[3] Mirzaali, M.J., Pahlavani, H. and Zadpoor, A.A., 2019. Auxeticity and stiffness of random networks: Lessons for the rational design of 3D printed mechanical metamaterials. Applied Physics Letters, 115(2), p.021901.

[4] Mirzaali, M.J., Cruz Saldívar, M., Herranz de la Nava, A., Gunashekar, D., Nouri-Goushki, M., Doubrovski, E.L. and Zadpoor, A.A., 2020. Multi-material 3D printing of functionally graded hierarchical soft–hard composites. Advanced Engineering Materials, 22(7), p.1901142.

[5] Saldivar, M.C., Doubrovski, E.L., Mirzaali, M.J. and Zadpoor, A.A., 2022. Nonlinear Coarse-graining Models for 3D Printed Multi-material Biomimetic Composites. arXiv preprint arXiv:2204.05152.

About the University Technology Exposure Program 2022

Wevolver, in partnership with Mouser Electronics and Ansys, is excited to announce the launch of the University Technology Exposure Program 2022. The program aims to recognize and reward innovation from engineering students and researchers across the globe. Learn more about the program here.