A Closer Look at USB Type-C Port Protection

Article #3 of our Circuit Protection Series. USB Type-C interface is everywhere - and getting more popular.

This is the third article in a 7-part series examining circuit protection. The series examines the challenges of high-speed circuit protection, as well as the many products and solutions used to solve them. This series is sponsored by Mouser Electronics, an online distributor of electronic components. Through their sponsorship, Mouser Electronics shares its passion for technologies that enable a safe and connected world.

One of the most up-and-coming high-speed serial interfaces is USB Type-C. USB Type-C cables can charge a laptop and offer 10 Gbps for fast transfers between devices. When considering how to protect USB and specifically Type-C, designers must focus on electrostatic discharge (ESD) and over-temperature events that could damage physical plastic casing or the electronic equipment. Further consideration must be given to the integrated circuits.

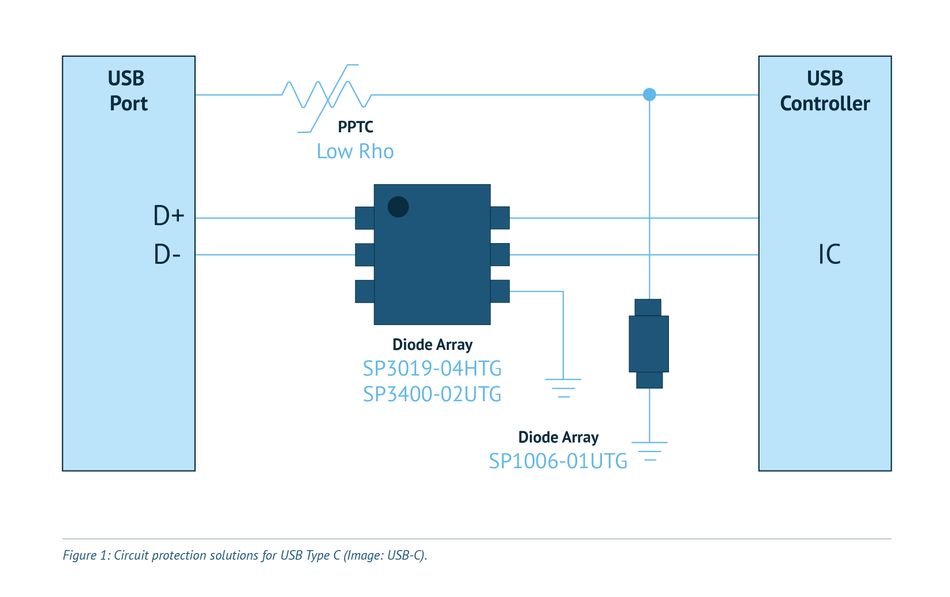

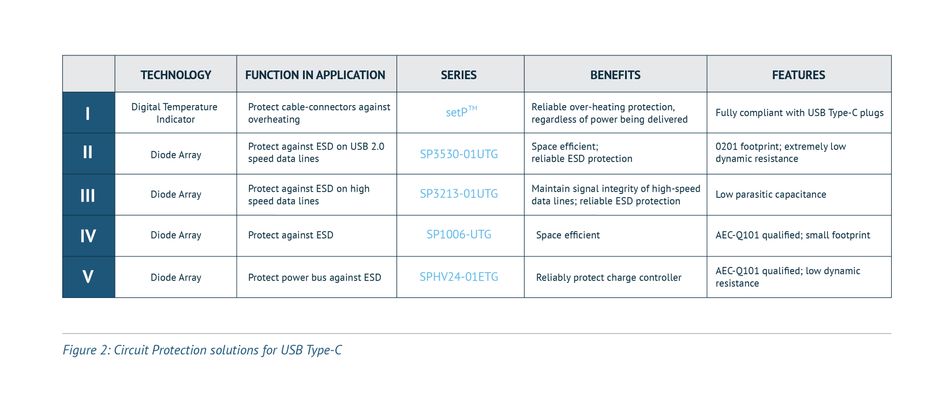

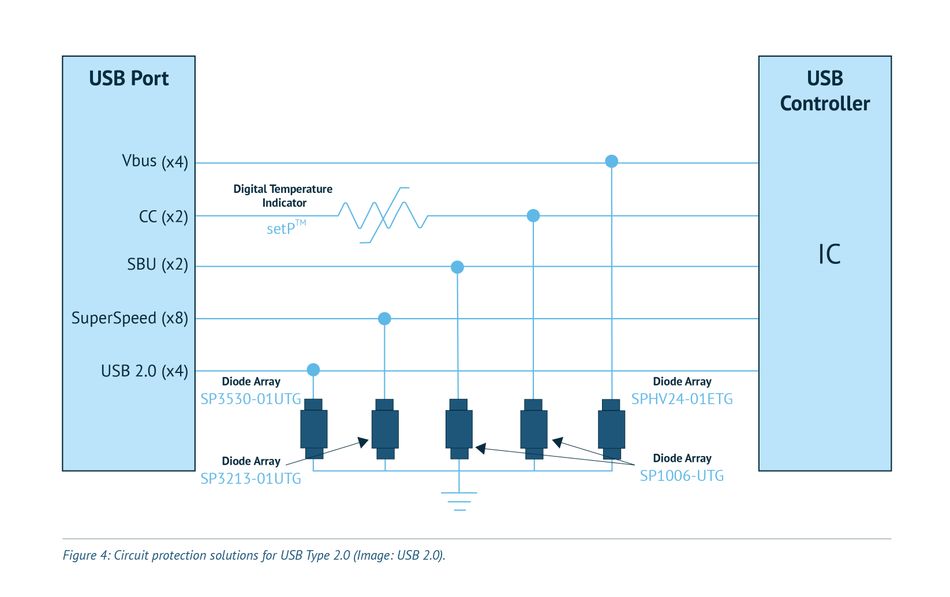

This article unpacks the table below examining USB-C protection in greater depth and outlines possible solutions by Littlefuse

V

Let’s start at the bottom of the table at Roman numeral five (V) and work our way up. One first notices an ESD protector for the USB-C port’s power lines. ESD can cause a user's electronic device to fail. Users should always be aware and cautious when interacting with their USB ports since even the tiniest amount of charge may generate an electrostatic discharge event that could damage your hardware. It is essential to protect any type of interface from ESD because we plug and unplug cables throughout our day at work and engage in physical contact, which generates static electricity on either side. The electrostatic spike can damage CMOS sensitive transceiver structures making such needed precautions necessary to avoid costly downtime from system-wide failures due to excess moisture build-up caused by humidity or condensation during winter months. The two sets of 12 pins are so close together that a short circuit can occur when plugging the port into your device. It's also possible for conductive particles to form an unintended connection across these pins. This will lead you to have extra protection against such hazards to not have anything happen at all. It is optimally sized for a power line with up to 20V. Typical ESD devices are only capable of 5V, 6V, or even 12V of sustained power.

IV

IV indicates protection for the CC line and the SBU lines. A Discrete Single-line Transient Voltage Suppressor is a device that helps protect the port from an ESD event. It does this by limiting voltage fluctuations and preventing damage to sensitive electronics when they're touched with high currents near power supplies without protection circuits. This can also lead to serious safety problems since designing these out beforehand could have prevented many accidents. The CC and SBU pins are next to the VBus pin, so they are exposed if there's a short-circuit condition. That can be fixed by using TVS diodes with 20V minimum breakdown strength on one side but must protect these two sensitive pads with only 12 volts provided from other sides. The data rate is slower, and a higher capacitance is OK. For data speeding, capacitance, and the relationship, the faster your data speed, the lower one wants capacitance. This is because capacitance can degrade the signal to a point where it attenuates, and it’s unreadable by the device receiving it. So on this line, because it’s lower speed, a higher capacitance device can be used and typically is lower in price.

III

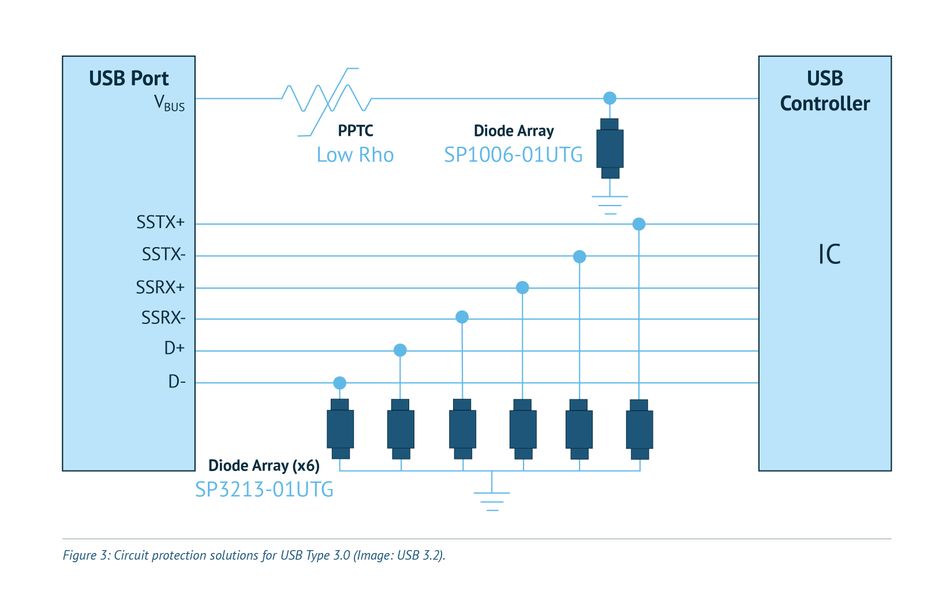

At III, one is at much faster data speeds. The fastest you’ll observe in a USB-C port is the super speed lines typically referred to as USB 3.0. Data rates are rising with 5Gbps, and engineers must find a way to protect sensitive information without adding signal distorting capacitance. The increased data transfer rate requires decreasing channel latencies, but current solutions may not be able- in some cases, even if they wanted to. Designers have been challenged to find voltage transient protection that can keep up and provide ESD protection for input lines from both static electricity or surges caused by lightning storms, etc. The introduction of additional differential data pairs helps protect more lines against ESD and discrete protection solutions. New silicon array devices, placed directly on those paths between two points, can protect the legacy interface. while also protecting these extra signals without adding too much bulk or weight onto them with bulky shielding materials such as metal foil layers found within traditional approaches before this invention came along. Up to eight of these could be in action at any one point in time. So this, in contrast to what you saw in IV, this SP3213 needs to be the lowest capacitance possible so that one makes sure that those high speeds are adequately protected, and that one does not interrupt when we’re not called upon.

II

II contains the USB 2.0 lines. The maximum level of ESD protection in modern IC chips is 2000V. While this may be sufficient for the manufacturing process, it will not offer enough survivability when your product goes into use, with much higher levels experienced by end-users. A common source of over-voltage transients is Electrostatic Discharges (ESD). The type expected at final products often leads to Human Interface Devices, followed closely by intermittent function errors, including data loss on stored files within memory. With the polymer-based PTC (Positive Temperature Coefficient) device, you can protect your devices from overcurrent events on USB power lines. The product reacts to an excessive current by changing its state and becoming highly resistive so that it doesn't draw any more electricity than necessary for protection purposes. II contains the USB 2.0 lines. USB 2.0 lines run at about 480Mbps, obviously, not quite as fast as the super speed lines but still need a moderate level of protection in terms of how faster they react and that they have a low enough capacitance to attenuate that signal again. The SP3530 is a good fit where it’s still low capacitance, but it doesn’t need to be the lowest level yet.

I

With the rise of Type-C cables that can deliver up to 100W charging power, safety and reliability are now primary requirements. But with a high current in a small space, there's an increased risk for failure overheating caused by an electrical short circuit. Many factors contribute towards these shorts, such as dust, moisture metals, debris etc. Engineers are attempting to have proper over-temperature protection. It’s different from what has been discussed on the other lines. It is vital because overheating faults can severely damage the electronics utilizing the USB-C port. The setP device that Littelfuse offers senses overheating. This configuration setP can go in a cable similar to ESD protectors.

Summary

USB Type C connectors are fast becoming the most common and versatile connection standard for personal devices. These connectors face unique challenges when it comes to protection and a solution that takes into account, speed, application, and type of use is necessary.

This article was initially published by Mouser and Littlefuse in an e-magazine. It has been substantially edited by the Wevolver team and electrical engineer Fahad Farooq. It's the third article of a 7-part series examining circuit protection. Future articles provide an overview of how to protect wired communication, the change of USB standards, and the importance of protecting against electrical stress in industrial automation environments.

Article one gave an overview of general ports.

Article two introduces electrical stress.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.