5 Ways to Realize Your Fast and Cost-Efficient CNC Machining

Product designing is a challenging work, as most manufacturing time and product cost are determined by initial product design. If the product is not designed for manufacturing and cost, it will be doomed to have low-processing efficiency and high-cost in product manufacturing.

Photo by Mastars on Unsplash

Product designing is a challenging work, as most manufacturing time and product cost are determined by initial product design. If the product is not designed for manufacturing and cost, it will be doomed to have low-processing efficiency and high-cost in product manufacturing. There’re several factors that affect the efficiency and cost of CNC Machining, including design, manufacturing time, material costs, etc.

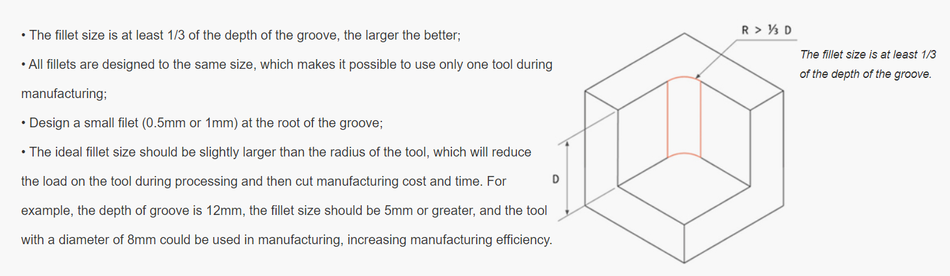

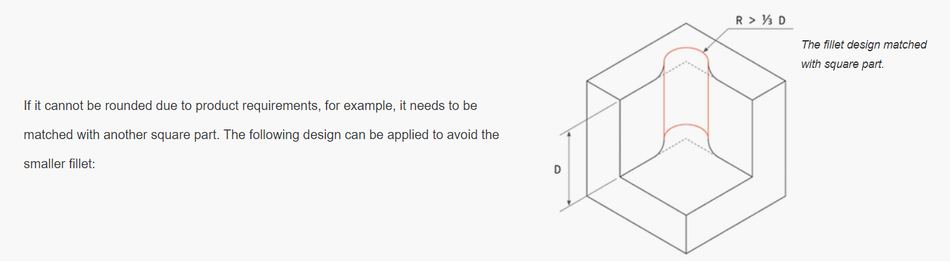

1. Design the fillet for inside vertical right angle

All CNC tools are cylindrical, and when machining the groove, a fillet consistent with the tools shape will be generated at the junction of the vertical surfaces of the groove. If the fillet of the vertical surface of the groove is designed too small, a smaller tool will be required. However, the processing efficiency of a small tool is not as efficient as a large tool, which will increase the manufacturing time and cost. To reduce cost and increase manufacturing efficiency:

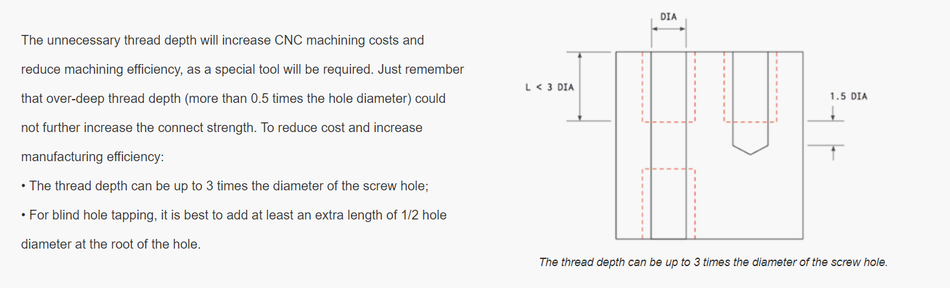

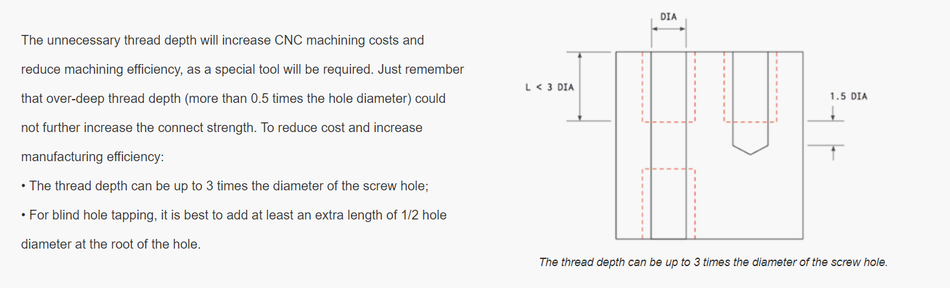

2. Reduce the thread depth

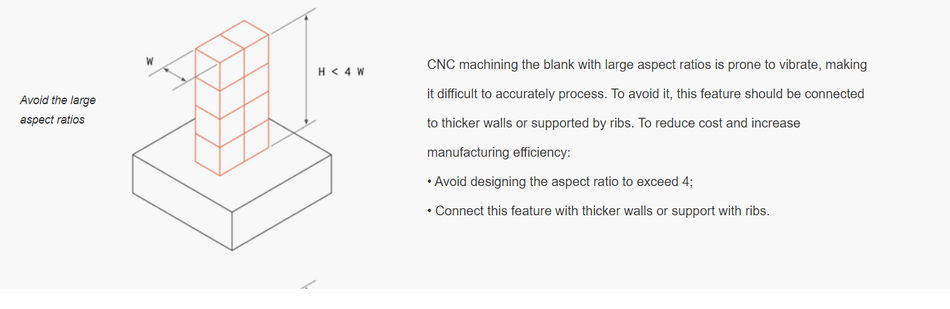

3. Avoid the large aspect ratios

3. Avoid the large aspect ratios

4. Take the processability of materials into consideration

The better the processability of a material, the easier the CNC machining of parts and the lower the manufacturing cost. The processability of the material depends on the physical properties of material. Generally speaking, the softer the material and the better the ductility, the easier it is to process.

For example, brass C360 has the best processability and can be rapid machined; Aluminum alloy (aluminum 6061 and 7075) also can be easily machined. The processability of steel is not quite good. Compared with aluminum alloy, steel requires more than twice the processing time. Certainly, the processability of different steels is different, for example the processability index of stainless steel 304 is 45%, while the index of stainless steel 303 is 78%. The latter is easier to process.

The processability of plastic materials depends on its rigidity and thermal properties. Plastic materials are easily melted and deformed at high temperatures during CNC Machining.

POM is the easiest material to be CNC machined, followed by ABS; PEEK and nylon are common engineering plastic materials that are difficult to process.

To reduce cost and increase manufacturing efficiency:

• Try to choose the materials with good processability, if allows.

5. Consider the price of raw materials

The price of raw material is the key factor in the cost of CNC machining products.The following shows the price ranking of common metal and plastic raw material blanks. For reference only, sort by price from low to high.

▲ Aluminum 6061 is obviously an ideal material, for its better processability and lower price. It is suitable for producing prototypes.

▲ The processability of both stainless steel 303 and brass C360 are good, and could be time-efficient in manufacturing. However, the price of raw materials is high. So, they are only suitable for mass production, which will balance the high price through short manufacturing time.

▲ As for the plastic materials, the price of ABS, nylon and POM is similar to that of aluminum 6061. However, plastic materials are more difficult to be CNC machined, and they are far from cost-efficient. To reduce cost and increase manufacturing efficiency:

• Choose the materials with lower price, especially for low-volume products.