Drywise In-Line Filament Dryer

An in-line filament dryer that continuously and reliably removes excess moisture from the filament during FDM/FFF 3D printing.

Technical Specifications

| Device | |

| Technology | |

| Interface | |

| Filament Path | |

| Filament Diameter | 2.85 |

| Compatible Materials | |

| Operating Sound | |

| Connectivity | |

| Dimensions and Weight | |

| Dryer with Desiccant Container | 590*500*145 |

| 0,5 | |

| Dryer with Packaging | 690*620*240 |

| 13,5 | |

| Warranty |

Overview

Problem

Different 3D printing materials are Hygroscopic to varying degrees with some absorbing moisture more readily than others. If moisture is present inside the filament at the time of printing, the results obtained will not be satisfactory. The moisture present will quickly evaporate and try to escape, creating voids and bubbles in the filament and affecting the flow out of the nozzle. This results in 3D prints which present visible artifacts and poor surface appearance. Furthermore, moisture present negatively affects color appearance, dimensional accuracy, and mechanical properties. A drying method, therefore, becomes necessary to appropriately treat these filaments, not only before printing but also during printing, especially for very sensitive materials or longer prints.

Solution

The Drywise Dryer is specially built for FDM/FFF 3D printing to remove excess humidity from filaments before and during printing. The novel in-line drying technology only dries the specific part of the filament needed during the printing process instead of as conventionally normal drying the entire spool. With Drywise there is virtually no downtime or pre-planning, as you dry as you print, resulting in huge time and effort savings, allowing you to focus on what really matters to you. Pre-calibrated profiles for specific filaments eliminate the guesswork and ensure the results are reliable and consistent.

Design

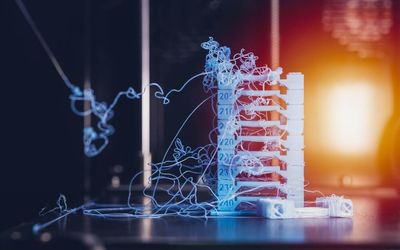

Main Components

The Drywise Dryer measures 520x500x145mm and extends to 620x500x145mm with the add-on and the drying capsule attached. For comparison it is roughly the same height as an Ultimaker S5 when standing side by side. It weighs around 12 kilograms with an additional half a kilo with the drying capsule connected.

On the front panel of the Drywise device there is a 4.3” capacitive touchscreen, USB type C port, a logo power switch and a functional LED logo are present. On the back panel meanwhile, one finds the input port, with a replaceable cover that can be switched to the add-on, the output port which houses a filament movement sensor and guiding LEDs, a fan (internal), a power socket (IEC C14), and the quick connectors for the drying capsule.

Features

The user-friendly UI guides the user all the way throughout the process. Interaction with the device happens via a 4.3” capacitive touch panel with guiding LED lights present at the front and back panels of the device. The filament path has clearly marked input and output ports and currently the system is designed to support only 2.85mm diameter filaments. A Drywise version for 1.75mm diameter filament is currently being developed and should be available in 2023. Device operates at 100-240V AC at 50-60Hz depending on the region and factory setting. Device operation is pretty straightforward, and a USB-C port is present for future system updates. Maximum rated power consumption is 350W.

Compatible Materials

Currently Drywise is calibrated for Nylon materials. Profiles for filaments from the main brands are already created and present on the device ready for use. Some of the brands include Luvocom, BASF, Covestro, Polymaker, Matterhackers, Jabil, Ultimaker, Radilon, Taulmann and many more. For compatibility with reinforced nylons and PAHT resin-based filaments, a specific add-on (sold-separately) is required. This ensures operation at the same level of satisfaction. The Drywise UI will guide the user towards which specific materials need this add-on. The updated list of all compatible materials can be found at drywise.co/materials.