Transforming Aluminum Extrusion: Advanced Computer Vision Solutions for Enhanced Quality Control and Industry Efficiency

Explore how advanced computer vision technology transforms quality control in metal manufacturing and why it represents the industry's future.

Introduction

Aluminum extrusion is a vital manufacturing process that shapes aluminum into components used in aerospace, automotive, and construction industries. Driven by its lightweight, strength, and recyclability, the global market for aluminum extrusion was valued at $93.4 billion in 2023 and is projected to reach $198.1 billion by 2033, reflecting its growing importance in sustainable and innovative application. However, despite its efficiency, the process faces challenges such as speed tears, which are small fractures that can compromise product integrity and lead to increased costs and material waste.

In today's competitive manufacturing landscape, traditional manual inspection methods for aluminum extrusion are increasingly inadequate due to their time-consuming nature, susceptibility to human error, and inability to detect defects like speed tears in real-time. As the demand for high-quality aluminum products grows, manufacturers increasingly turn to advanced technologies like artificial intelligence (AI) and computer vision to streamline operations.

Matroid, a leader in AI-powered computer vision solutions, has emerged as a leader in this field. Their automated speed tear detection system offers a cutting-edge solution to one of the most pressing challenges in aluminum extrusion. This article explores how Matroid’s technology transforms quality control in metal manufacturing and why it represents the industry's future.

The Challenges of Quality Control in Aluminum Extrusion

The aluminum extrusion process is complex, with quality influenced by factors such as alloy composition, temperature regulation, extrusion speed, and die design. Maintaining uniform quality is challenging due to defects like surface scratches, die lines, and, most critically, speed tears. These tears are caused by excessive friction or localized stress during extrusion. They are particularly problematic as they can develop unexpectedly and spread rapidly, leading to significant material loss if not identified promptly. The fast pace of production lines and the subtle nature of these defects further complicate detection efforts.

Historically, manual inspection has been the primary method for identifying defects. However, this approach is labour-intensive, prone to human error, and inconsistent due to operator fatigue and subjective judgment. Traditional methods also struggle with false positives and lack systematic data collection to correlate defects with process parameters, making it difficult to identify root causes and implement preventative measures. These limitations increase production costs and highlight the need for more robust quality control systems to ensure high-quality aluminum extrusion products while minimizing waste and inefficiencies.

Matroid’s AI-Powered Solution: Redefining Defect Detection for Modern Manufacturing

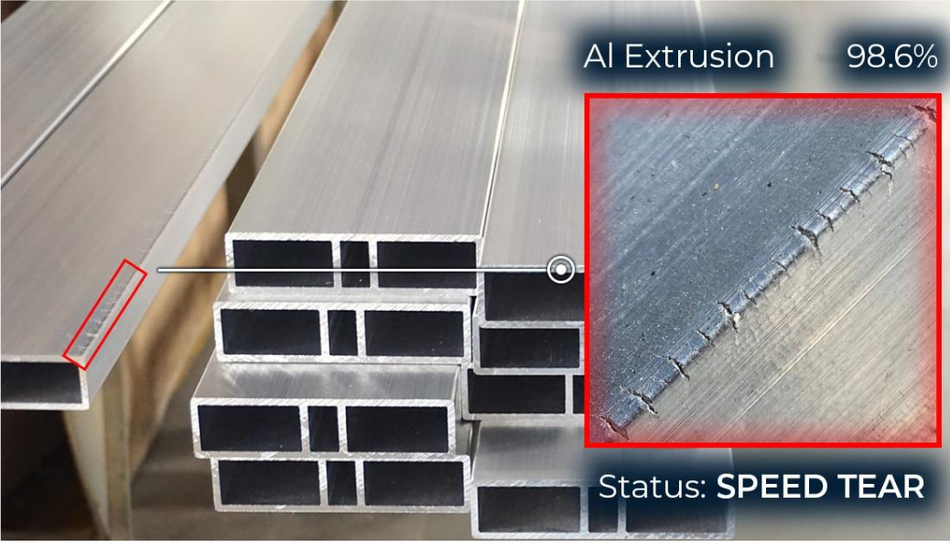

Matroid, a leader in computer vision solutions, collaborated with a leading aluminum extruder and offered an innovative approach to speed tear detection using artificial intelligence. The AI-powered speed tear detection system is a prime example of how computer vision can address the challenges of aluminum extrusion. The system analyses real-time video footage of the extrusion process, identifying speed tears as they occur. This real-time capability is critical for minimizing waste and identifying defects before they escalate into more significant issues.

Optimized lighting techniques were implemented to enhance the system’s effectiveness and improve defect contrast, making it easier for AI to detect even subtle imperfections. Additionally, Matroid collaborated closely with the aluminum extruder to capture operator expertise. Sourcing and defining various speed and hot tear profiles created a plant-wide standard for all packaging operators, metallurgists, and process engineers. This collaboration ensured the AI system was trained on accurate and representative data.

One of the standout features of Matroid’s solution is its adaptive AI detector. The system was trained on a diverse dataset encompassing various extrusion profiles, ensuring it could adapt to different shapes and configurations. This adaptability is crucial for manufacturers dealing with various product types. Furthermore, Matroid employed a smart annotation strategy, distinguishing between actual defects and non-defect patterns using newly created “tear definitions.” This approach allowed the detector to quickly differentiate critical tears with minimal training data, significantly speeding up the implementation process.

Matroid’s solution's accuracy is one of its key advantages. The system can detect even the most minor defects, ensuring that only high-quality products move forward in the production line. Additionally, the system is highly scalable, making it suitable for manufacturers of all sizes. Matroid’s system is also designed with ease of integration in mind. The solution can be seamlessly incorporated into existing production lines, minimizing disruption and maximizing Region of Interest (ROI). This makes it an attractive option for manufacturers looking to modernize their operations without overhauling their infrastructure. By utilizing Matroid's computer vision technology, manufacturers can improve product quality, achieve substantial cost savings, and enhance operational efficiencies.

Conclusion

Matroid’s AI-powered computer vision solution marks a significant advancement in quality control for aluminum extrusion manufacturing. The system’s ability to detect speed tears in real time, combined with optimized lighting techniques and adaptive AI algorithms, addresses long-standing challenges in the industry. Its seamless integration into existing production lines, scalability, and user-friendly design make it a powerful tool for manufacturers seeking to reduce waste, cut costs, and enhance product quality.

AI and computer vision are poised to play a transformative role in manufacturing in the coming years. As Industry 4.0 evolves, integrating predictive analytics and Internet of Things (IoT) technologies will significantly enhance defect detection and prevention. These advancements will enable manufacturers to transition from reactive quality control to proactive strategies, effectively minimizing defects before they occur.

Additionally, as global emphasis on sustainability increases, technologies like Matroid’s will become indispensable in reducing material waste and optimizing resource efficiency. Leveraging AI-driven solutions allows manufacturers to improve operational efficiency while contributing to a more sustainable and innovative manufacturing ecosystem. Matroid’s pioneering approach is solving current challenges and setting the stage for a smarter, more efficient future in aluminum extrusion.

To learn more about how Matroid’s AI-driven solutions can enhance your manufacturing operations, visit Matroid’s website.

References:

https://simmal.com/the-advantages-of-aluminium-extrusion-in-manufacturing/

https://vocal.media/01/aluminum-extrusion-a-vital-manufacturing-process-driving-innovations

https://www.verifiedmarketresearch.com/product/aluminum-extrusion-market/

https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

https://aimlprogramming.com/services/ai-enabled-aluminum-extrusion-monitoring/

https://www.matroid.com/computer-vision-in-metal-forming-precision-efficiency-and-roi/

https://www.matroid.com/case-studies/how-matroids-ai-computer-vision-can-transform-workplace-safety/

https://aluminumextrusions.net/aluminum-extrusion-quality-control/

https://globalaluminium.com/quality-of-aluminium-extrusion-manufacturing/

https://www.chaluminium.com/common-aluminum-extrusion-defects-causes-and-solutions