The Victoria Hand Project Expands Prosthetics Access in Ukraine

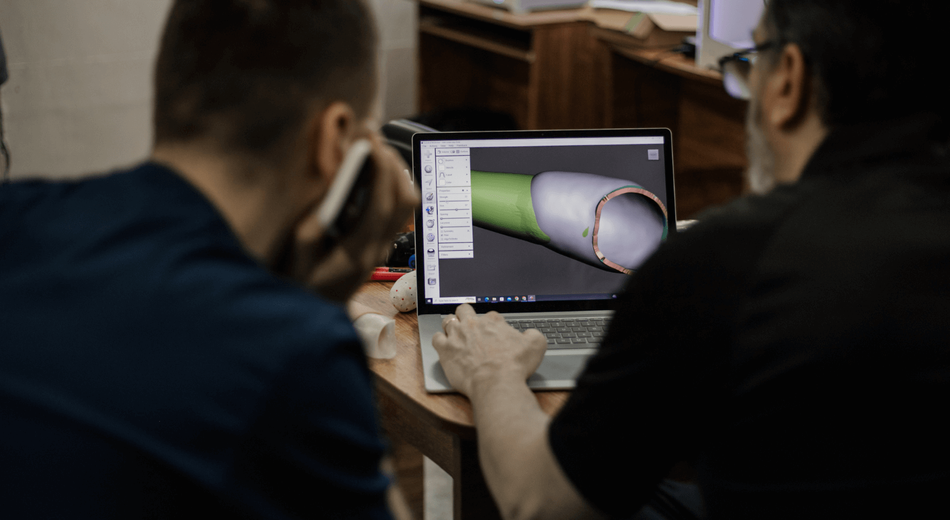

With amputees in war-torn Ukraine nearing half million, the Canadian non-profit organization Victoria Hand Project (VHP) is combining innovative materials from BASF Forward AM with UltiMaker 3D Printers’ robust construction to provide high-performance prosthetics to those in urgent need.

Source: Victoria Hand Projects

This article was first published on

forward-am.comWith amputees in war-torn Ukraine nearing half million, the Canadian non-profit organization Victoria Hand Project (VHP) is combining innovative materials from BASF Forward AM with UltiMaker 3D Printers’ robust construction to provide high-performance prosthetics to those in urgent need.

Victoria Hand Project seeks to fundraise $200,000 to support their “Hands for Ukraine” campaign

With the launch of this campaign, VHP will raise funds to support on-demand prosthetic care for individuals living in Ukraine. According to reliable news sources, as of January 30, 2023, over 40,000 Ukrainians have been injured in the war. Experts estimate between 25% and 35% of that number are amputees who will need specialized medical support. This is in addition to the already 400,000 existing amputees in the region, most of which have little no access to prosthetic care and these numbers are predicted to grow in the future.

In January of 2023, through the help of donations from generous supporters, VHP completed a successful pilot project in Ukraine. A team member traveled to two partner sites to conduct initial training, set up equipment, and demonstrate fittings by providing five in-need amputees with prosthetic arms. VHP now seeks to makes these partnerships in Ukraine permanent and on-going by training local prosthetists and technology experts to 3D print, assemble, and provide Victoria Hands on-demand to those who need them.

The full expansion into Ukraine will include:

- Fully equipping two partner sites in Lviv and Vinnytsia with 3D printing and scanning tools

- Fully equipping both partner sites with supplies for prosthetic fittings

- Fully funding high-quality prosthetic care for 100 Ukrainian amputees and laying groundwork for many more to receive care

- If the fundraising efforts exceed the initial goal set, additional monies will be added to increase the number of prosthetic arms being produced.

Donations can be made at: Victoria Hand Project

“By harnessing the print quality and mechanical properties of Forward AM Ultrafuse® PLA PRO1 in addition to the exceptional dependability from UltiMaker, Victoria Hand Project creates prosthetic hands that not only meet functional requirements, but also empower users. These hands are not just tools; they become symbols of resilience, self-assurance, and durability in the daily lives of amputees.” – Michael Peirone, CEO of Victoria Hand Project.

Established in July of 2015, VHP has formed clinical partnerships in 11 countries and created a network of compassionate professionals who rely on the patronage of generous donors to continue to spread hope and restore independence to individuals facing limb loss.

By utilizing innovative 3D printing technology and materials, VHP works with unwavering dedication to create affordable and customizable prosthetic arms — the Victoria Hands. As they continue to expand, VHP depends on trusted Additive Manufacturing collaborators like BASF Forward AM and UltiMaker to provide the needed support to facilitate long-term, sustainable prosthetic care around the globe.

Tapping into the strength, versatility and consistency of Forward AM’s Ultrafuse® PLA PRO1

BASF Forward AM began supporting Victoria Hand Project in early 2022 when VHP started using Ultrasfuse® PLA PRO1 for its superior durability and repeatability as well as the ability to provide users with a simple and easy printing experience. This innovative material delivers precise and detailed prosthetic components, not only enhancing the aesthetics of the prosthesis but more importantly contributing to the functionality of the hand itself as the material is optimized for quality, speed, strength, and reliability resulting in performance levels which exceed those of traditional filaments.

This aligns with VHP’s commitment to excellence as they recognize the significance of creating prosthetic hands that not only function well, but also inspire beauty and confidence in their users. The outstanding mechanical properties of Ultrafuse® PLA ensure reliability, longevity and durability, enabling prosthetic hands to withstand the daily challenges they face and the smooth and polished finish elevates the overall aesthetics, instilling self-confidence and empowering recipients with a profound sense of pride.

“As an industry leader in 3D printing, we strive to consistently provide best-in-class materials and solutions for applications limited only by our customers’ imaginations. But the opportunity to support VHP — an organization using Additive Manufacturing to reshape the lives of amputees around the world — is something that goes beyond the day-to-day tasks of doing business. It adds a feeling of deep purpose and a stronger sense of why we do what we do. It’s not just printed plastic. It’s hope, independence, and a better quality of life.” – Martin Back, CEO and Managing Director of Forward AM

Building on the trusted reliability and performance of UltiMaker 3D Printers

With their robust construction and stable functionality, UltiMaker printers and software provide users with comprehensive engineering solutions and consistent 3D printing. These state-of-the-art machines are also easy to operate, which is crucial for clinicians who may be inexperienced with this pioneering technology.

As a 3D printing partner for VHP for the past 7 years, UltiMaker is an ardent supporter of the organization’s mission to deliver prosthetic care to more people in need worldwide. UltiMaker 3D printers offer reliability and flexibility in compact, low-maintenance, and easy-to-use machines, allowing local clinicians to design and create custom prosthetic arms faster and more efficiently. By working closely together to ensure a seamless printing experience, the collaborative results of UltiMaker FFF printers along with Forward AM’s PLA PRO1 provide the ideal combination for producing dependable, long-lasting 3D printed prosthetic hands in challenging locations. This partnership is vital for achieving the proper fit, functionality, and aesthetics of the prosthetic hands created resulting in a seamless workflow and effectively supporting clinicians by helping fulfill their mission of providing life-changing prosthetic hands to as many individuals as possible.

“We are thrilled to be a long-term partner of Victoria Hand Project and continue to support its mission to deliver prosthetic hands to people in need. With the UltiMaker 3D printing ecosystem on location, clinicians can print parts on-demand, providing better prosthetic support to their communities. By expanding access to prosthetic care with 3D printing, we believe we can help address the needs of individuals with limb loss or limb differences, promoting empowerment, inclusivity, and overall well-being.” – Nadav Goshen, CEO of UltiMaker.

Receiving a Victoria Hand is transformative; a functional prosthetic arm is an incredible tool to help amputees regain independence, hope, and embrace opportunities to live more fulfilling and happier lives. The positive impact a prothesis can have goes far beyond the recipient alone. It’s life-changing effects ripple throughout families, caretakers, the community and beyond.